Method for manufacturing autoclaved bricks by utilizing contaminated acid sludge

A technology of polluted acid residue and autoclaved brick, which is applied in the field of resource recycling and reuse and building materials, can solve the problems of rising pollutant concentration, the advent of treatment technology, and irregular construction, so as to achieve social and economic harmony, a wide range of raw material sources, and technological progress. Technically simple and practical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

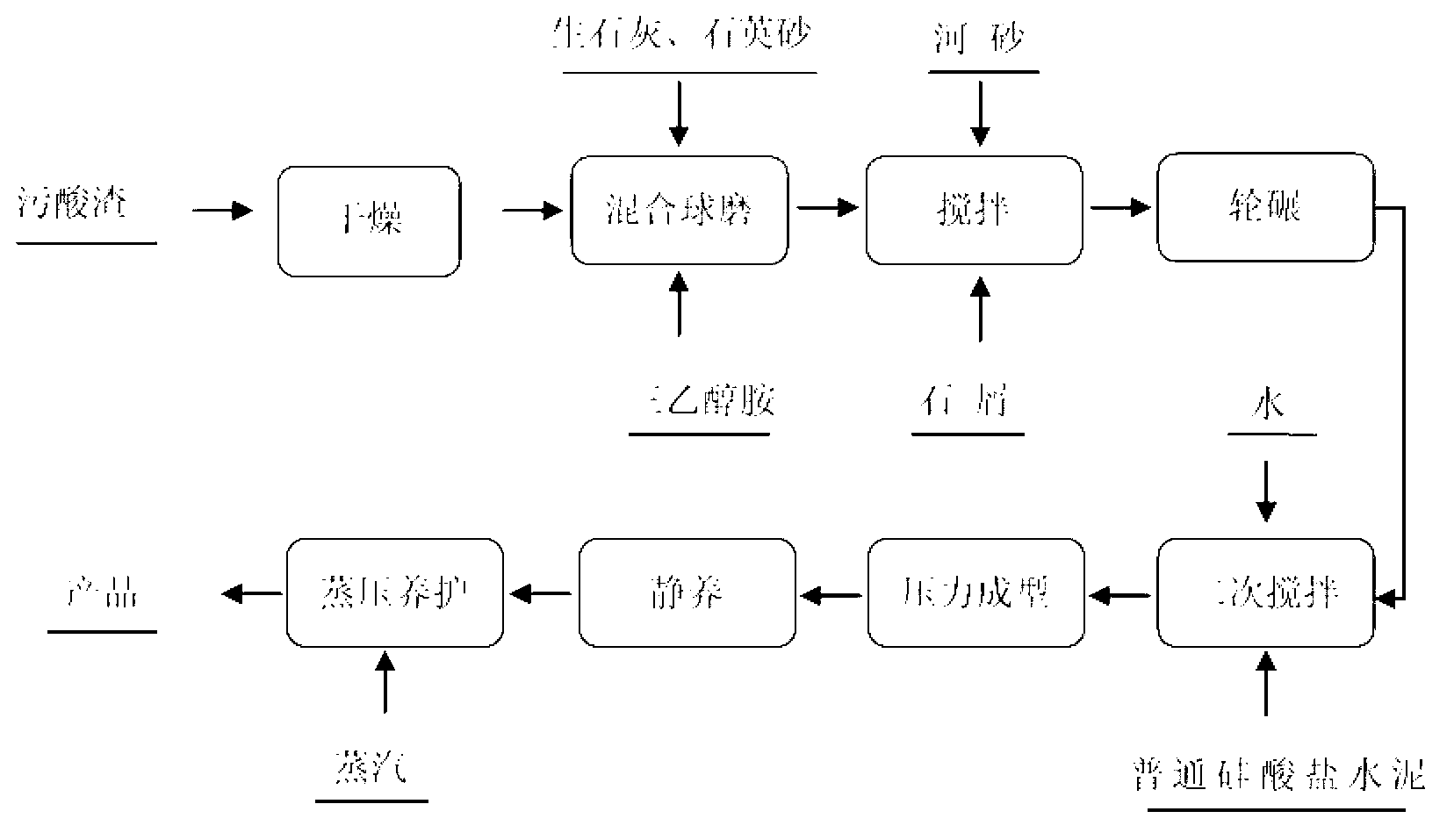

[0036] A method for preparing autoclaved bricks from dirty acid slag, comprising the steps of:

[0037] Step 1, drying: collect the dirty acid slag and put it in an oven, and dry it at 50°C;

[0038] Step 2, ball milling: Put the dried dirty acid slag into the ball mill, add triethanolamine after running for 10 minutes, the amount added is 0.02% of the mass of the dried dirty acid slag, continue to run for 15 minutes, then add quicklime and quartz sand, add The amount is respectively 2% and 3% of the mass of the dirty acid slag, run for 10 minutes;

[0039]Step 3. Stirring: Add the ball-milled material to the mixer, add river sand and stone chips for pre-mixing for 8 minutes, slowly add water to moisten, control the moisture content to 11%, and stir for 10 minutes; the added amount of the river sand is the ball-milled material 30% of the mass, the particle size is 0.5mm, and its silica content is greater than 70%, and the mud content is less than 2%; the addition of the stone...

Embodiment 2

[0046] A method for preparing autoclaved bricks from dirty acid slag, comprising the steps of:

[0047] Step 1, drying: collect the dirty acid slag and put it in an oven, and dry it at 60°C;

[0048] Step 2, ball milling: Put the dried dirty acid slag into the ball mill, and add triethanolamine after running for 12 minutes, the addition amount is 0.1% of the mass of the dried dirty acid slag, continue to run for 20 minutes, then add quicklime and quartz sand, add The amount is respectively 2.5% and 5% of the mass of dirty acid slag, run for 15 minutes;

[0049] Step 3. Stirring: Add the ball-milled material to the mixer, add river sand and stone chips for pre-mixing for 10 minutes, slowly add water to moisten, control the moisture content to 13%, and stir for 15 minutes; the added amount of the river sand is the ball-milled material The mass is 45%, the particle size is 2.0mm, and its silica content is greater than 70%, and the mud content is less than 2%; the added amount of...

Embodiment 3

[0056] A method for preparing autoclaved bricks from dirty acid slag, comprising the steps of:

[0057] Step 1, drying: collect the dirty acid slag and put it in an oven, and dry it at 55°C;

[0058] Step 2, ball milling: Put the dried dirty acid slag into the ball mill, add triethanolamine after running for 11 minutes, the addition amount is 0.06% of the mass of the dried dirty acid slag, continue to run for 18 minutes, then add quicklime and quartz sand, add The amount is respectively 2.3% and 4% of the mass of the dirty acid slag, running for 12 minutes;

[0059] Step 3. Stirring: Add the ball-milled material to the mixer, add river sand and stone chips for pre-mixing for 9 minutes, slowly add water to moisten, control the moisture content to 12%, and stir for 12 minutes; the added amount of the river sand is the ball-milled material The mass is 38%, the particle size is 1.2mm, and its silicon dioxide content is greater than 70%, and the mud content is less than 2%. The ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com