Raw material ratio design method for semi-rigid base layer of cement stabilized steel slag

A semi-rigid base and cement-stabilized technology, applied in the direction of ratio control, instruments, control/regulation systems, etc., can solve problems such as restrictions on large-scale popularization and application, large differences in steel slag composition, and unstable material properties, so as to improve the utilization rate and Applicability, cost reduction, and the effect of solving ecological and environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

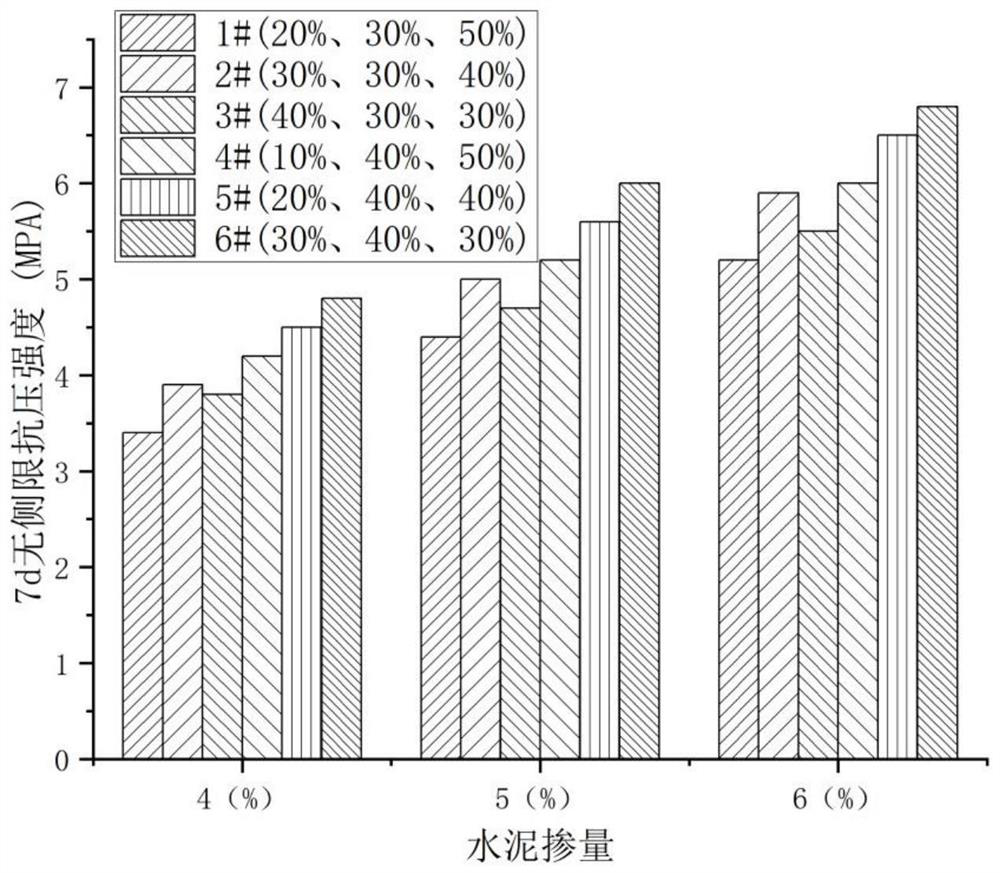

[0022] The present invention will be further described below in conjunction with a specific example, but the content of the present invention is not limited to the following examples. The purpose is to verify through experiments that the design method of the raw material ratio of a semi-rigid base layer with cement-stabilized steel slag proposed by the invention can meet the requirements of the "Highway Pavement Base Construction Technical Specifications" (JTG / TF20-2015) with the lowest cost raw material ratio. The requirement for 7d unconfined compressive strength to be greater than 4Mpa under heavy traffic on medium-highway and first-class highway base. Specific examples are as follows.

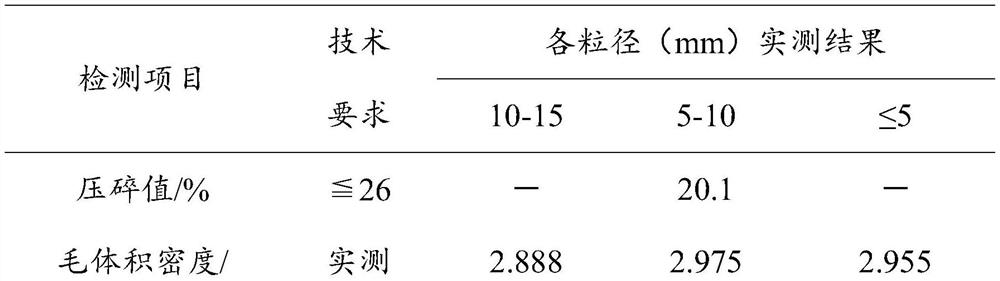

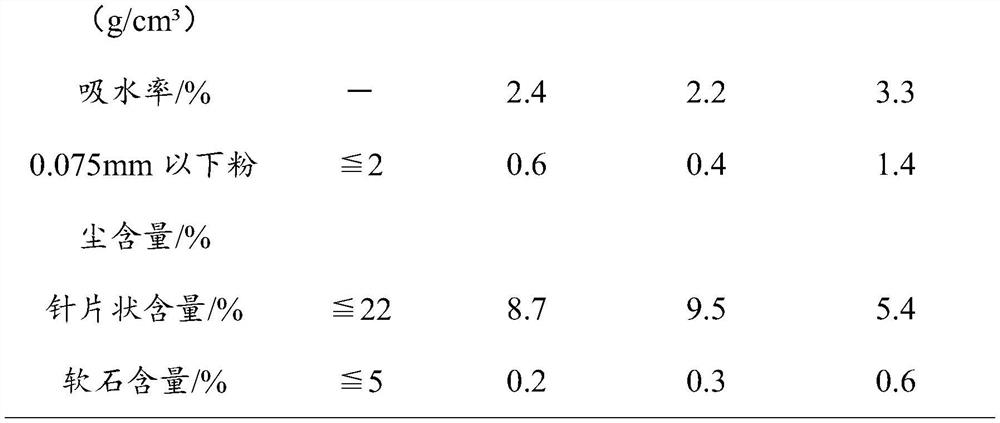

[0023] 1. Perform screening test on steel slag and test the basic properties of steel slag material

[0024] (1) First, use crushing equipment to crush the steel slag aggregate into steel slag with a particle size of less than 15mm, and then use a screening test to screen the steel slag ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com