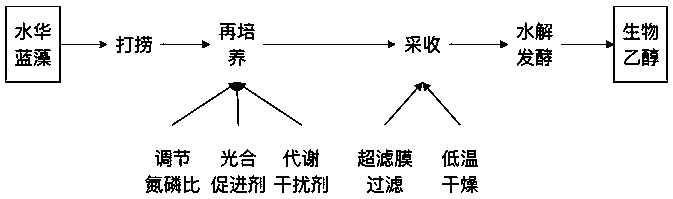

Method for preparing bioethanol from bloom-forming cyanobacteria

A technology of blooming cyanobacteria and bioethanol, which is applied in the fields of bioenergy technology and environmental protection to achieve the effects of increasing sugar content, increasing yield, and solving ecological and environmental problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Salvage and collect the cyanobacteria in the Yangwan area of Taihu Lake when the water blooms broke out. The absolute dominant species is Microcystis, and the impurities visible to the naked eye are removed. Inoculate the collected bloom cyanobacteria into the photobioreactor, add Taihu Lake water to make the chlorophyll concentration 2-4mg / L, add NaNO 3 and K 2 HPO 3 , placed at 6000 lx, and cultured at 28°C. Regularly measure the dry weight and soluble total sugar production to calculate the sugar content; measure the chemical oxygen demand (COD) and biochemical oxygen demand (BOD) of the algae cell contents, and calculate the BOD / COD to characterize its biodegradability.

[0029] Under the condition of nitrogen-phosphorus ratio of 10:1, adding 0.01-0.05‰ photosynthesis accelerator and 1-3‰ metabolism disruptor, the dry weight increased from 0.527 g / L to 1.758 g / L, and the total soluble sugar increased from 33.7 mg / L to 995.6 mg / L. Compared with uncultured cyano...

Embodiment 2

[0031] Dissolve 1.2 g of the recultivated algae powder directly in 40 ml of 2mol / L hydrochloric acid solution to prepare a 30 g / L algae solution. High temperature hydrolysis at 121°C for 30 min, and the hydrolyzate was filtered through a 0.45 μm filter membrane. The changes of soluble total sugar and reducing sugar before and after hydrolysis were measured. The soluble total sugar and reducing sugar of the recultivated algal flour before hydrolysis were 17.0 g / L and 1.9 g / L, accounting for 56.6% and 6.4% of the dry weight, respectively; after hydrolysis, they were 17.9 g / L and 17.3 g / L , accounting for 59.8% and 57.5% of the dry weight, respectively. After hydrolysis, the proportion of reducing sugar in total sugar increased from 10.9% to 96.2%.

[0032] At the same time, the uncultivated algal powder was treated under the same conditions, and it was found that the total soluble sugar and reducing sugar before hydrolysis were 1.9 g / L and 1.2 g / L, accounting for 6.2% and 4% o...

Embodiment 3

[0034] The hydrolyzed NaOH solid was adjusted to pH=6.5. When the OD value of the cultured yeast is about 2, centrifuge at 4000 r / min for 3 minutes, discard the supernatant, add pure water to shake well, centrifuge and discard the supernatant, and repeat twice. According to the inoculation amount of 150 ml of Saccharomyces cerevisiae (OD value about 2) per 1 g of algae powder, that is, 50 ml of 30 g / L algae liquid inoculates 225 ml of yeast. The hydrolyzate was added to a 100 ml airtight sample bottle and fermented at 35°C for 48 h at a speed of 150 r / min. Filter the fermentation broth through a 0.22 μm organic filter membrane, take 5ml of the filtrate and seal it in a 20ml headspace sampling bottle, and measure the ethanol content by sampling headspace gas chromatography.

[0035]30 g / L algae powder re-cultivated produced bioethanol with a concentration of 6.52 g / L and an ethanol yield of 21.7 %, while 30 g / L algae powder without re-cultured produced a bioethanol concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com