Preparation method of biochar

A biochar and filtrate technology, applied in the field of biomass resource utilization, can solve the problems of limited adsorption performance and stability, few surface functional groups, and limited adsorption sites on the surface of biochar, and achieve rich pore structure and stability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

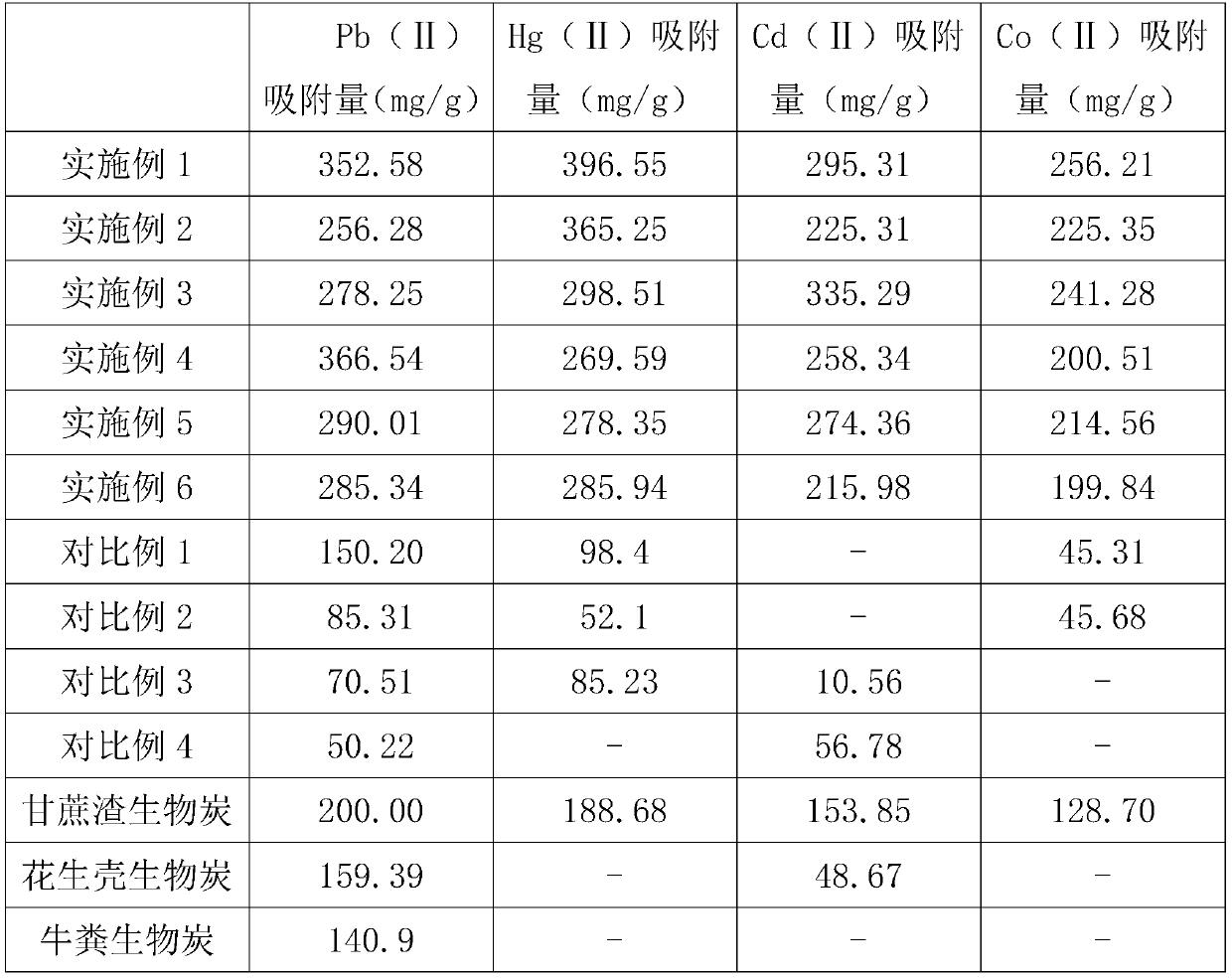

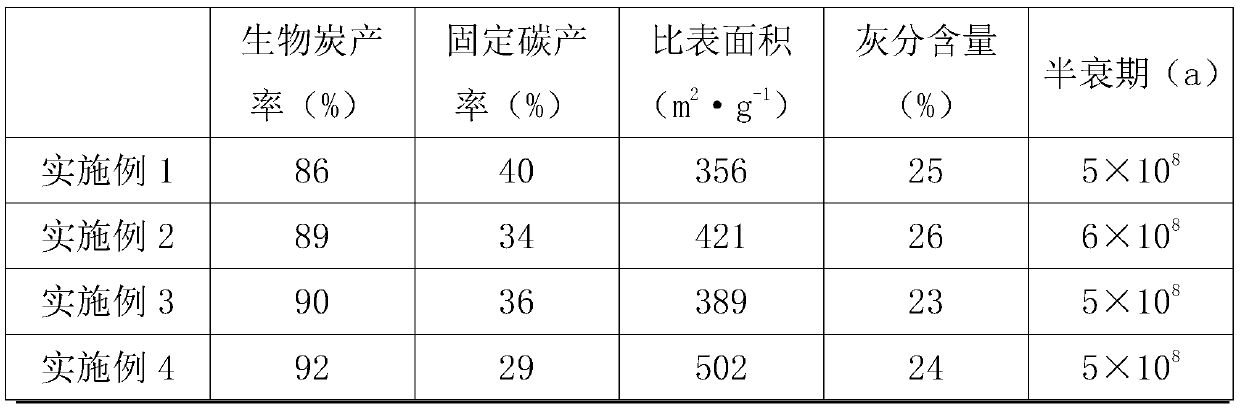

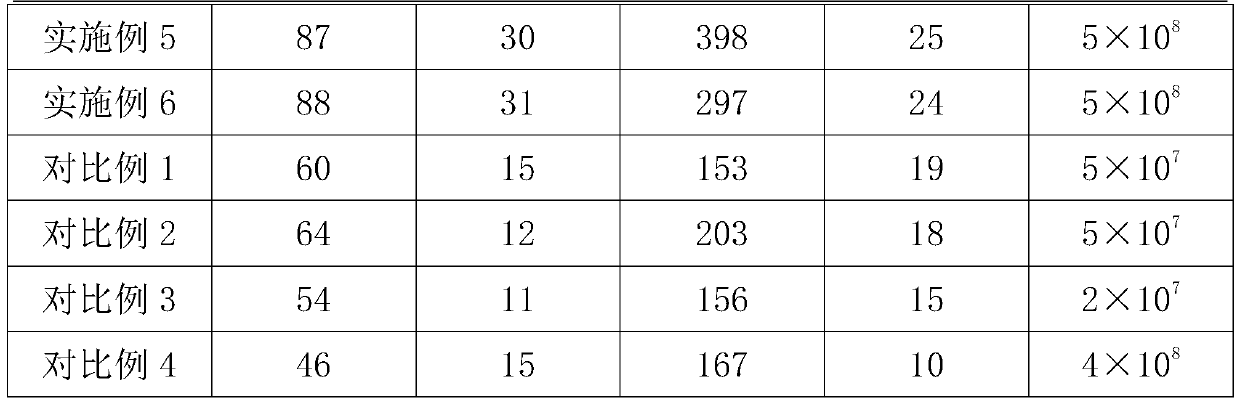

Examples

Embodiment 1

[0031] (1) Mix the fallen leaves and branches of trees produced in the process of greening waste urban landscaping and suburban forestry tending, fruit tree pruning, dry, and crush to 100 mesh, then put it into a container, and add a mass fraction of 30% Hydrochloric acid solution, the addition is 2wt% of the greening garbage particles, soak the greening garbage particles, stir, the stirring speed is 200r / min, and the stirring time is 30min, the greening garbage particles soaked in hydrochloric acid are put into the microwave reactor, and the greening garbage particles are heated at 300W / min m 2 React under the power of 15min, after the reaction is over, take out the reactant and set aside;

[0032] (2) Filter the above reactant under reduced pressure, collect the filtrate in a container, add amylase to the filtrate, the mass ratio of the filtrate to amylase is 60:1, add deionized water with 3 times the mass of the filtrate , add hydrochloric acid solution, adjust the pH to 8...

Embodiment 2

[0036] (1) Mix the fallen leaves, tree branches, fallen leaves and dead branches in the process of urban greening and landscaping, suburban forestry tending, fruit tree pruning, drying, and crushing to 100 meshes, then put them into a container, add The mass concentration is 30% hydrochloric acid solution, the addition amount is 2wt% of the green garbage particles, soak the green garbage particles, stir, the stirring speed is 250r / min, and the stirring time is 30min, put the green garbage particles soaked in hydrochloric acid into the microwave reaction In kettle, at 300W / m 2Under the power of the reaction for 20min, after the reaction, take out the reactant and set aside;

[0037] (2) Filter the above reactant under reduced pressure, collect the filtrate in a container, add amylase to the filtrate, the mass ratio of the filtrate to amylase is 60:1, add deionized water with 3 times the mass of the filtrate , add hydrochloric acid solution, adjust the pH to 8, add fresh chicke...

Embodiment 3

[0041] (1) Mix the fallen leaves, tree branches, fallen leaves and dead branches in the process of urban greening and landscaping, suburban forestry tending, fruit tree pruning, drying, and crushing to 110 mesh, then put it into a container, add The hydrochloric acid solution with a mass fraction of 30% is added in an amount of 2wt% of the greening garbage particles, soaked in the greening garbage particles, and stirred at a stirring rate of 200r / min for 30min, and the greening garbage particles soaked in hydrochloric acid are put into the microwave reaction In kettle, at 300W / m 2 Under the power of the reaction for 20min, after the reaction, take out the reactant and set aside;

[0042] (2) Filter the above reactant under reduced pressure, collect the filtrate in a container, add amylase to the filtrate, the mass ratio of the filtrate to amylase is 60:1, add deionized water with 3 times the mass of the filtrate , add hydrochloric acid solution, adjust the pH to 9, add fresh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com