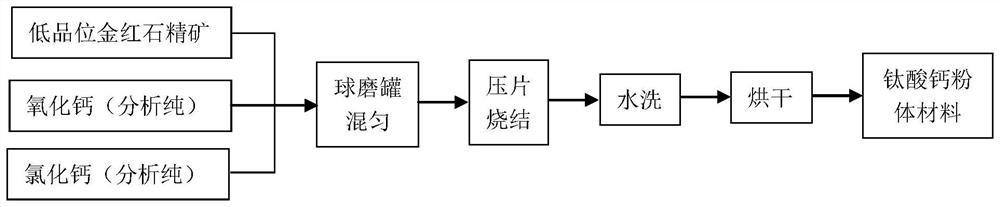

A method for preparing calcium titanate adsorption material by using low-grade rutile concentrate

An adsorption material, low-grade technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc. problems, to achieve the effect of solving ecological environment problems, reducing temperature, and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

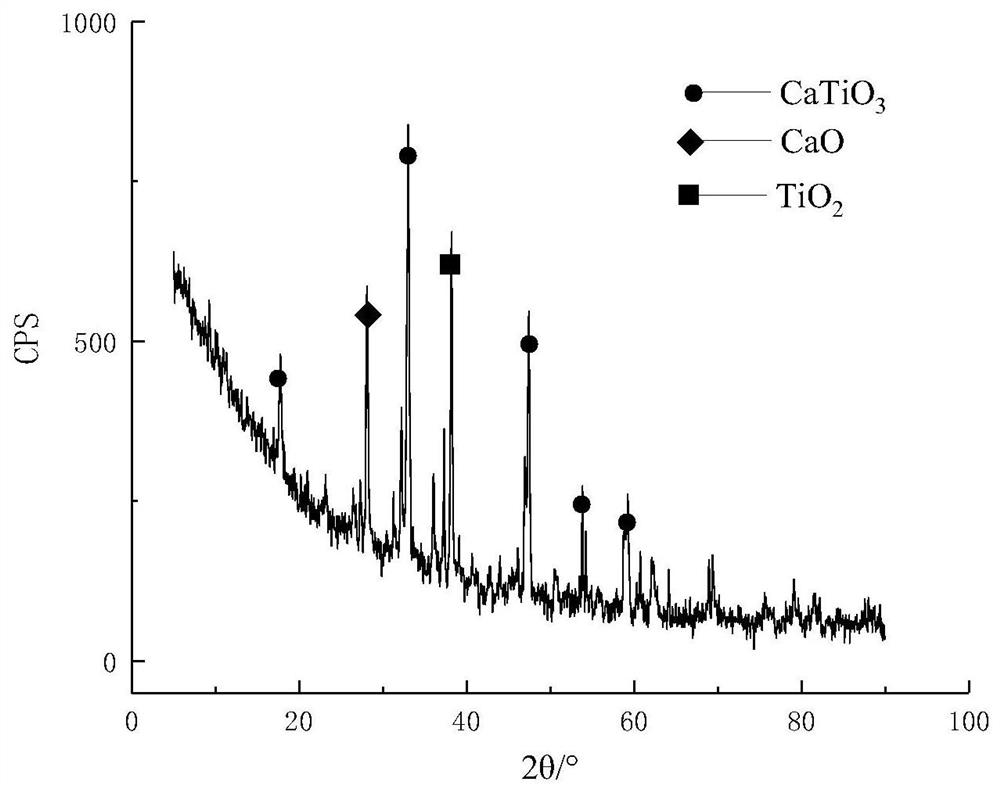

[0027] Mix 4 g of low-grade rutile concentrate with a particle size of 70 μm, 2.8 g of analytically pure calcium oxide, 1 g of analytically pure calcium chloride, and 1 g of analytically pure potassium silicate, and put it into a ball mill for grinding for 1 hour; pass the mixture through a tablet machine, Press the material sheet with a diameter of 20mm and a height of 10mm under the pressure of 30Mpa; put the material sheet into a muffle furnace at 750°C for 2 hours, and cool it naturally with the furnace, and wash the roasted material repeatedly with deionized water until no Cl - exist and dry to obtain calcium titanate powder material.

[0028] Take 1g of calcium titanate powder material and add it to 250mL of heavy metal ion solution containing copper (300mg / L), lead (600mg / L) and cadmium (300mg / L), perform magnetic stirring, take samples at regular intervals, filter, take solution, and the content of heavy metal ions in the solution was measured by atomic absorption spec...

Embodiment 2

[0033] Mix 4 g of low-grade rutile concentrate with a particle size of 70 μm, 2.8 g of analytically pure calcium oxide, 1 g of analytically pure calcium chloride, and 1 g of analytically pure potassium silicate, and put it into a ball mill for grinding for 1 hour; pass the mixture through a tablet machine, Pressed into material pieces with a diameter of 20mm and a height of 10mm under a pressure of 30Mpa; put the material pieces into a muffle furnace at 800 ° C for 3 hours, and cooled naturally with the furnace. - exist and dry to obtain calcium titanate powder material.

[0034] Take 1g of calcium titanate powder material and add it to 250mL of heavy metal ion solution containing copper (400mg / L), lead (800mg / L) and cadmium (400mg / L), carry out magnetic stirring, take samples at regular intervals, filter, take solution, and the content of heavy metal ions in the solution was measured by atomic absorption spectrophotometer to obtain the adsorption amount of heavy metal ions ad...

Embodiment 3

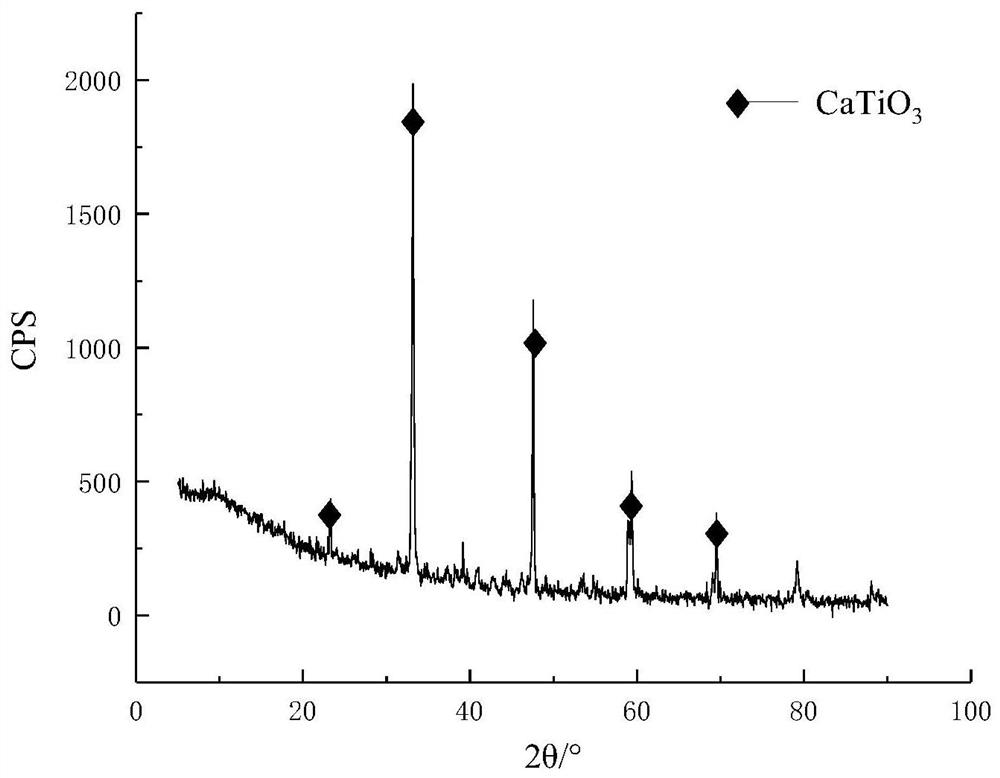

[0039] Mix 5g of low-grade rutile concentrate with a particle size of 70μm, 3g of analytically pure calcium oxide and 2.4g of analytically pure calcium chloride, and put it into a ball mill for grinding for 2 hours; pass the mixture through a tablet machine and press it under a pressure of 30Mpa. A material piece with a diameter of 20mm and a height of 10mm; put the material piece into a muffle furnace at 900°C for 3 hours, and cool it naturally with the furnace. That is, the calcium titanate powder material is obtained.

[0040] Take 1g of calcium titanate powder material and add it to 250mL of heavy metal ion solution containing copper (350mg / L), lead (700mg / L) and cadmium (350mg / L), carry out magnetic stirring, take samples at regular intervals, filter, take solution, and the content of heavy metal ions in the solution was measured by atomic absorption spectrophotometer to obtain the adsorption amount of heavy metal ions adsorbed by calcium titanate.

[0041] The scanning ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com