Wire continuous connector

A technology of connectors and wires, which is applied in the field of electric wires, can solve the problems of easy falling off of insulating tape, potential safety hazards of large power consumption, and easy slipping of insulating sleeves, etc., and achieve the effect of strong overall insulation performance, high work efficiency, and firm combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

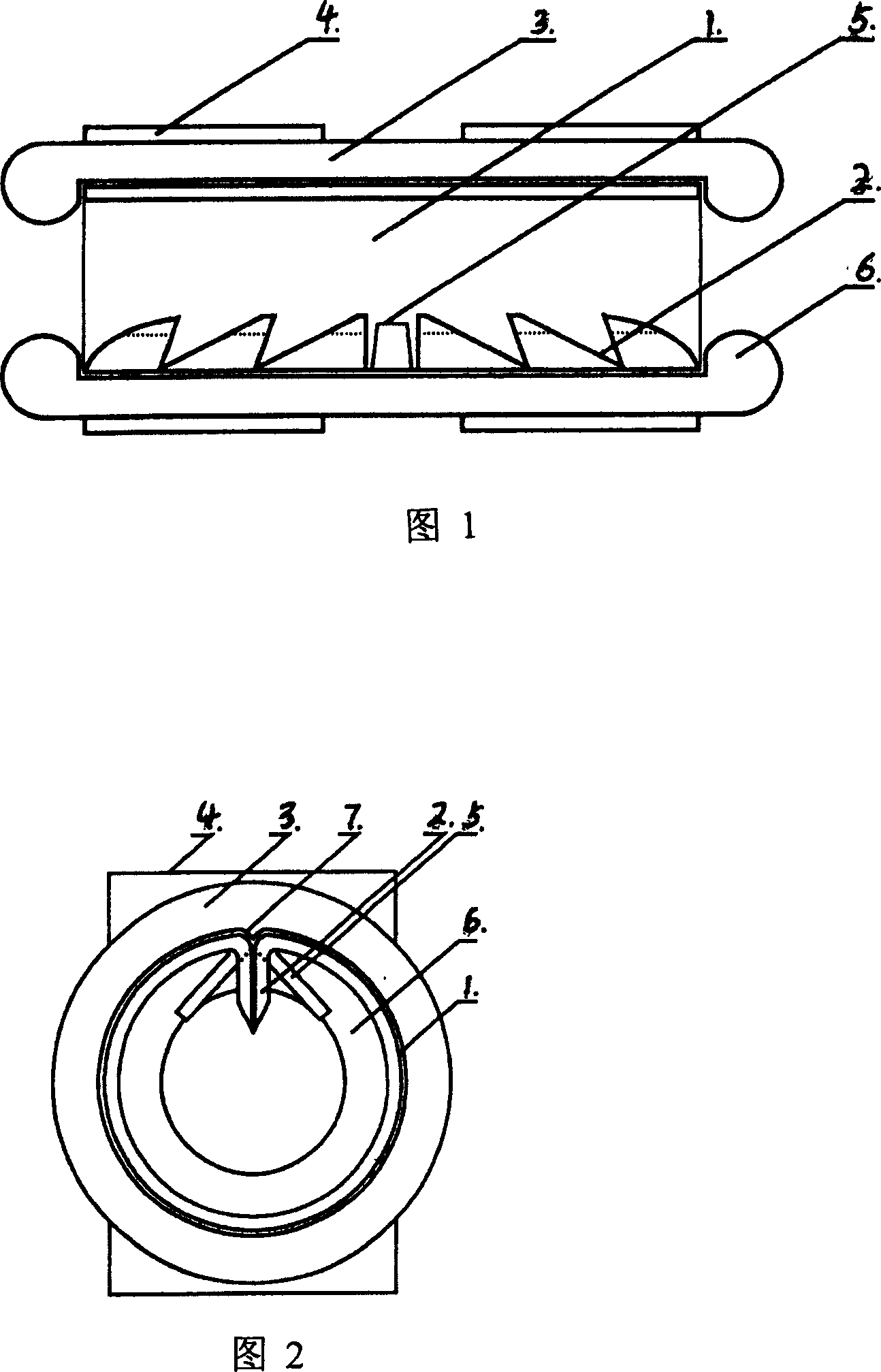

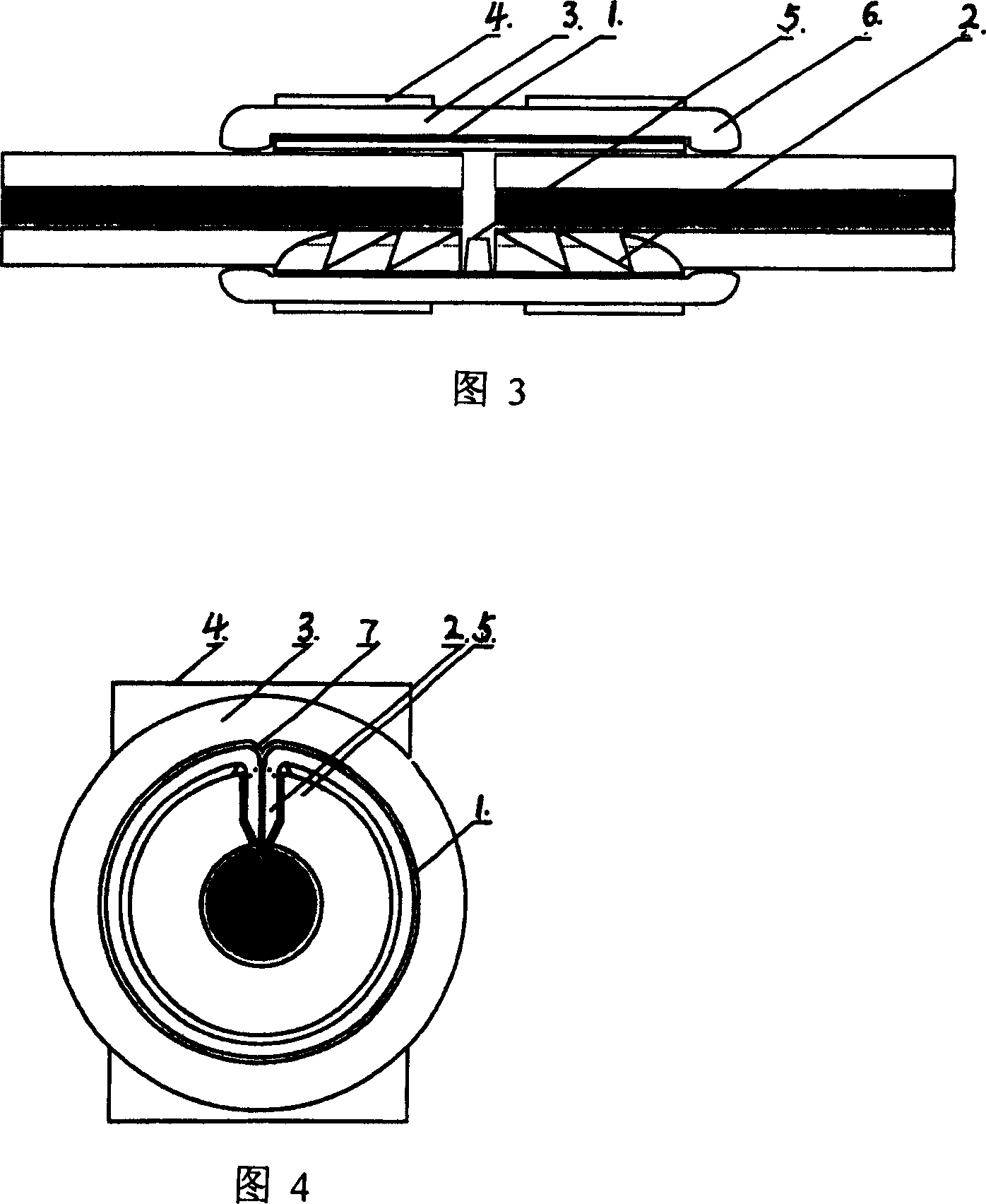

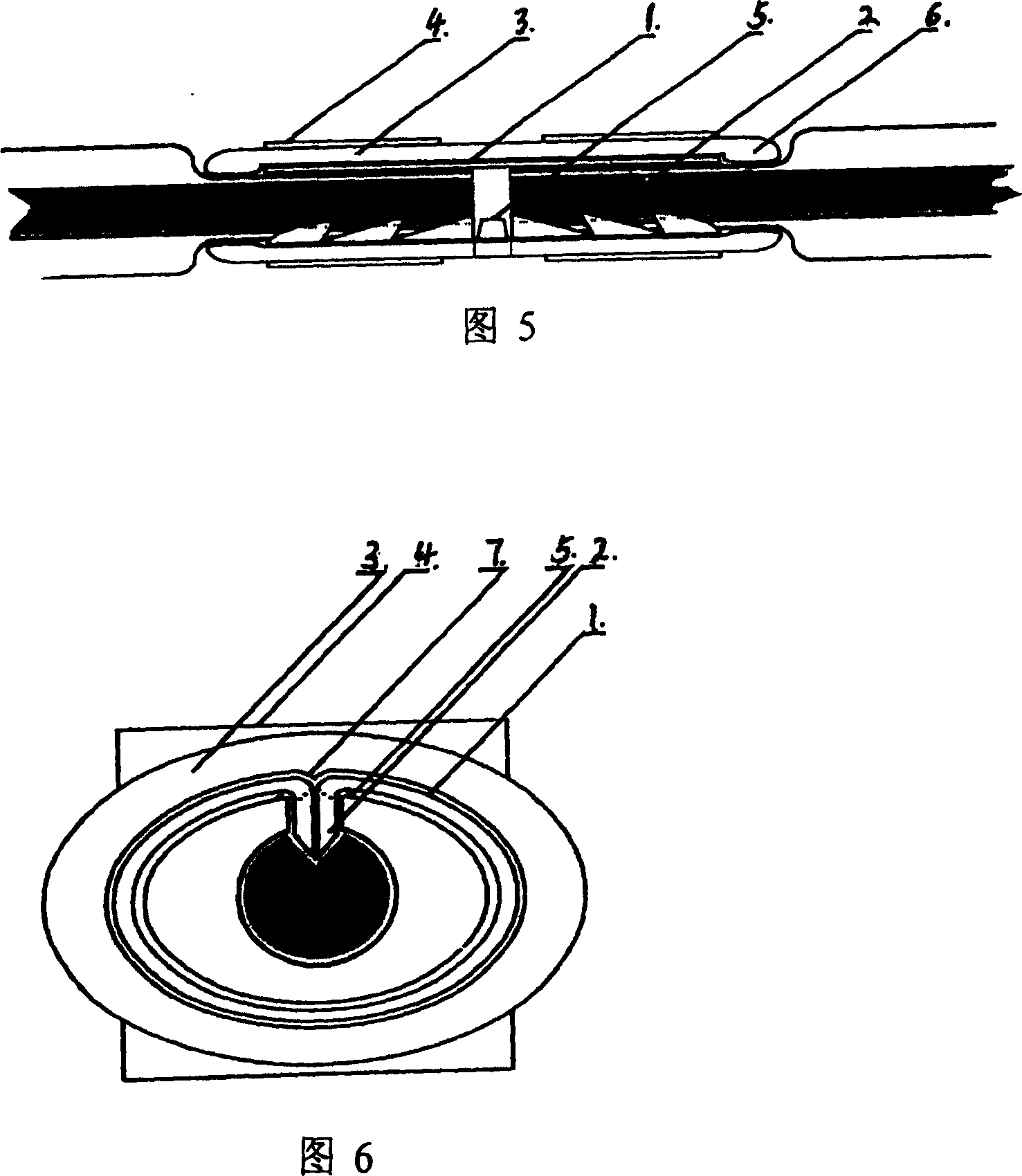

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0010] As shown in the accompanying drawings, the present invention is a special connection piece for electric wires, which is mainly composed of a metal ring sleeve 1 , an insulating sleeve 3 and a crimping pad 4 . The metal ring sleeve 1 is a cylindrical sleeve formed by curling metal sheets with good conductivity and ductility such as copper and aluminum, and the two butt edges respectively extend into the metal ring sleeve 1 to form a V-shaped angled protrusion On the inner surface of the metal ring sleeve 1, the raised part of the butt joint is cut into a zigzag shape to form two evenly distributed crimping teeth 2; a certain gap is left at the crimp joint of the metal ring sleeve 1 as a strip groove . The middle position in the metal ring sleeve 1 is also provided with a cable positioning tooth 5 protruding from the inner surface. The cable posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com