Modified wire adapting piece

A technology for wire connection and electrical conductivity, which is applied to the needle tip/slotted plate contact used to penetrate the insulated wire/cable core wire, etc., which can solve the problems of high production process requirements, easy falling off of insulating tape, and high operation accuracy. , to achieve the effect of strong operability, simple production and simplified connection steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

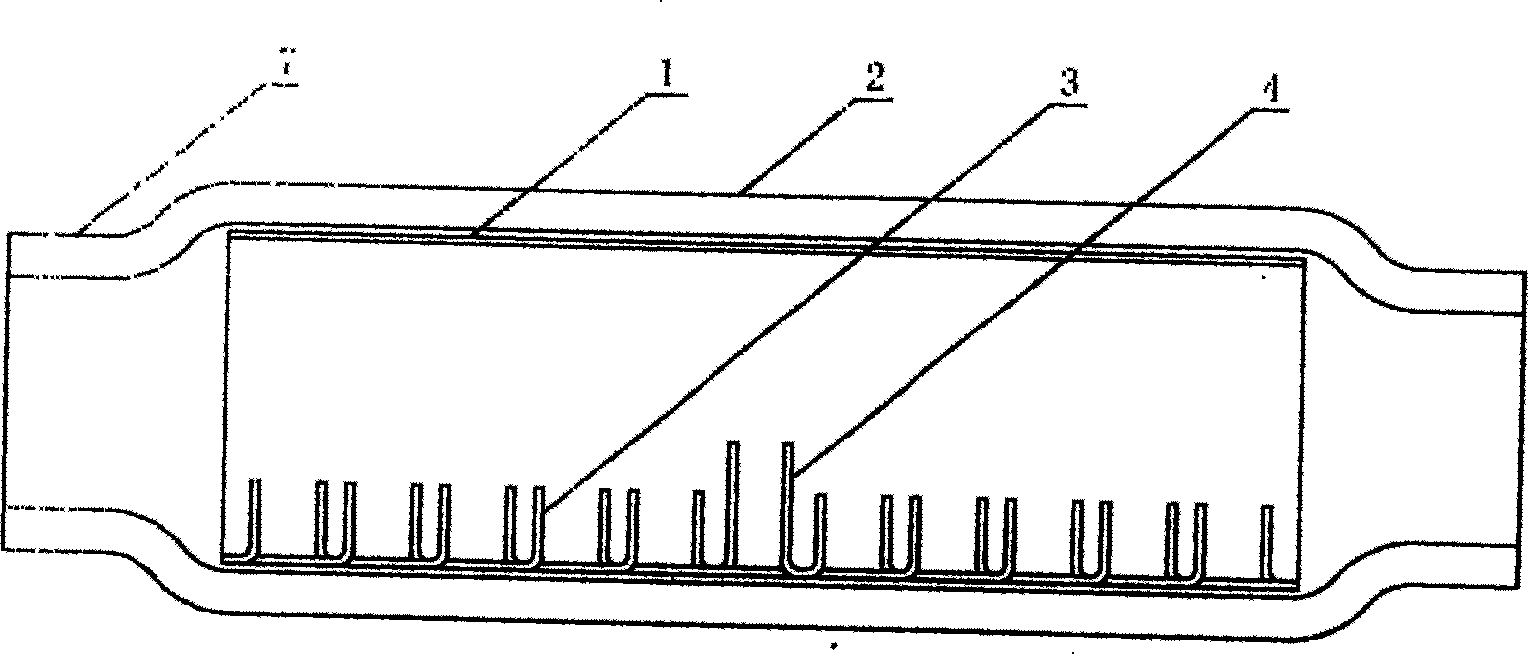

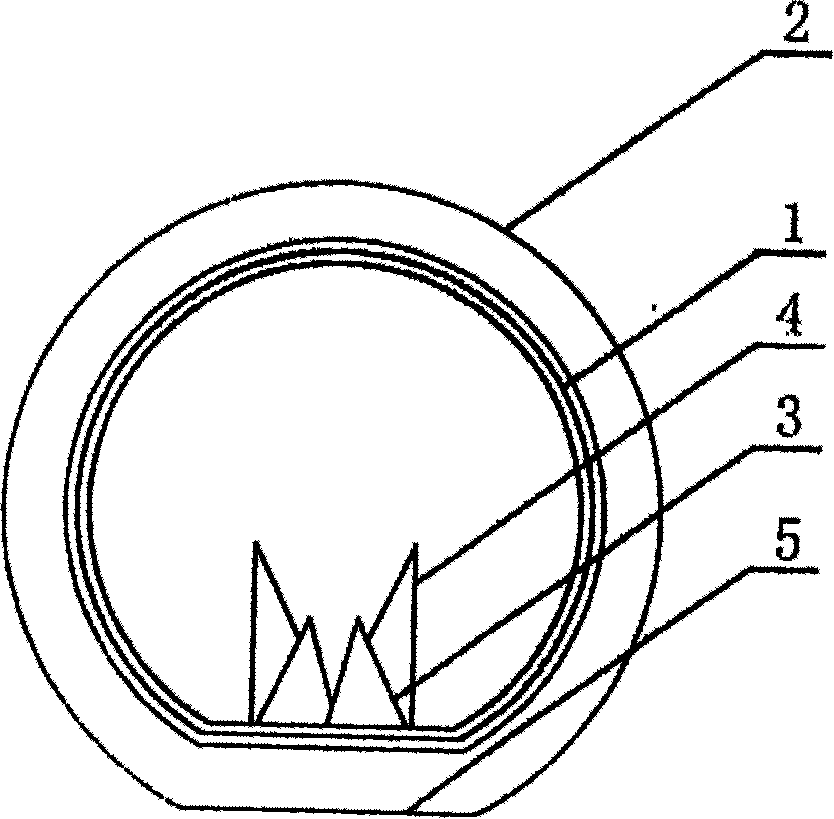

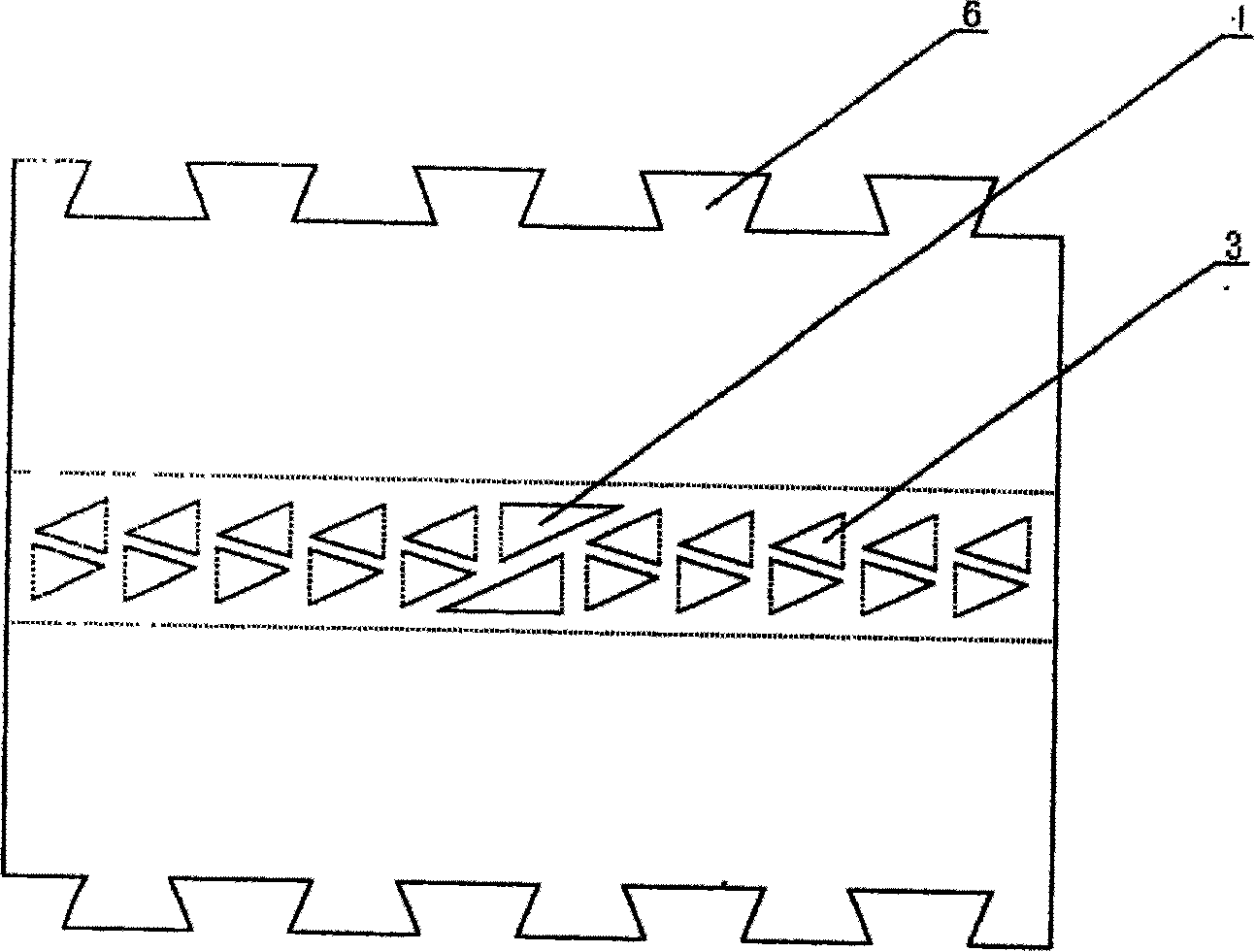

[0011] The invention is an improved wire connector, which includes a metal sleeve 1 and an insulating sleeve 2 . Such as image 3 As shown, the metal sleeve 1 is made by bending a square metal plate with good electrical conductivity. A plurality of triangular metal plate blocks are folded horizontally in the middle of the inner side of the metal plate, and after being folded, they are perpendicular to the inner surface of the metal sleeve 1. The crimping tooth 3 is formed, and the tooth end of the crimping tooth 3 is pointed, which is beneficial to penetrate the insulating layer of the wire. The above-mentioned multiple crimping teeth 3 form a crimping tooth row, which is generally designed as two rows, and the crimping teeth 3 in each row are arranged in reverse. In the middle of each row of crimping teeth 3, there is a positioning tooth 4 that is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com