Addition-type mold rubber and preparation method thereof

A technology of mold glue and addition molding, applied in the field of addition molding mold glue and addition molding mold glue for making crystal drills, can solve the problems of low brightness of crystal drills, affecting the service life of mold glue, short service life, etc. The effect of improved brightness, long service life and high economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

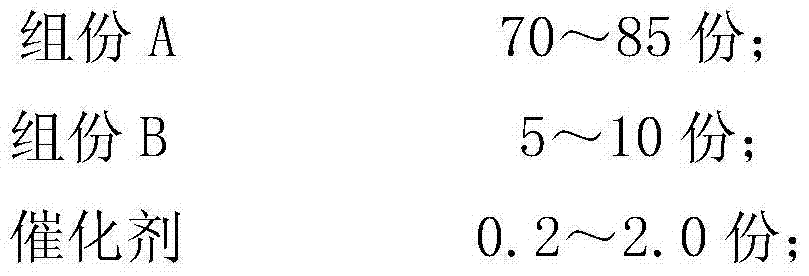

[0037] A kind of addition mold glue of the present embodiment, its raw material formula is made up of each component of following parts by weight:

[0038]

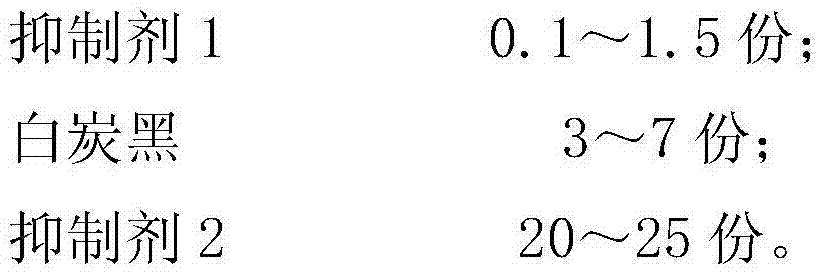

[0039] The structural formula of the above-mentioned component A is shown in the general formula (I):

[0040]

[0041]

[0042] In the above formula (I), a=90;

[0043] The structural formula of the above-mentioned component B is shown in the general formula (II):

[0044]

[0045] In the above formula (II), b=10 and c=12.

[0046] The above-mentioned catalyst is a Castel platinum catalyst with a platinum content of 3000 pmm; the white carbon black is commercially available white carbon black, and the inhibitor 1 is 3,5-dimethyl-1-hexyn-3-ol.

[0047] The structural formula of the above-mentioned inhibitor 2 is shown in the general formula (III):

[0048]

[0049] In the above formula (III), d=12.

[0050] The preparation method of above-mentioned addition mold glue comprises the steps:

[0051] Accor...

Embodiment 2

[0053] A kind of addition mold glue of the present embodiment, its raw material formula is made up of each component of following parts by weight:

[0054]

[0055]

[0056] The structural formula of the above-mentioned component A is shown in the general formula (I):

[0057]

[0058] In the above formula (I), a=98;

[0059] The structural formula of the above-mentioned component B is shown in the general formula (II):

[0060]

[0061] In the above formula (II), b=5 and c=14.

[0062]The above-mentioned catalyst is a Castel platinum catalyst with a platinum content of 3000 pmm; the white carbon black is commercially available white carbon black, and the inhibitor 1 is 2-propyn-1-ol.

[0063] The structural formula of the above-mentioned inhibitor 2 is shown in the general formula (III):

[0064]

[0065] In the above formula (III), d=10.

[0066] The preparation method of above-mentioned addition mold glue comprises the steps:

[0067] According to the ab...

Embodiment 3

[0069] A kind of addition mold glue of the present embodiment, its raw material formula is made up of each component of following parts by weight:

[0070]

[0071] The structural formula of the above-mentioned component A is shown in the general formula (I):

[0072]

[0073] In the above formula (I), a=95;

[0074] The structural formula of the above-mentioned component B is shown in the general formula (II):

[0075]

[0076] In the above formula (II), b=13 and c=15.

[0077] The above-mentioned catalyst is a Castel platinum catalyst with a platinum content of 3000 pmm; the white carbon black is commercially available white carbon black, and the inhibitor 1 is 3,5-dimethyl-1-hexyn-3-ol.

[0078] The structural formula of the above-mentioned inhibitor 2 is shown in the general formula (III):

[0079]

[0080] In the above formula (III), d=15.

[0081] The preparation method of above-mentioned addition mold glue comprises the steps:

[0082] According to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com