Inner spray welding anticorrosive wear resistant oil pipe and machining method and machining device

A technology for anti-corrosion and wear-resistant processing equipment, applied in the field of deep-hole processing, can solve the problems of falling off, no deep-hole processing, easy peeling of the coating, etc., and achieves the effect of simple structure, improved anti-corrosion effect, and good anti-corrosion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

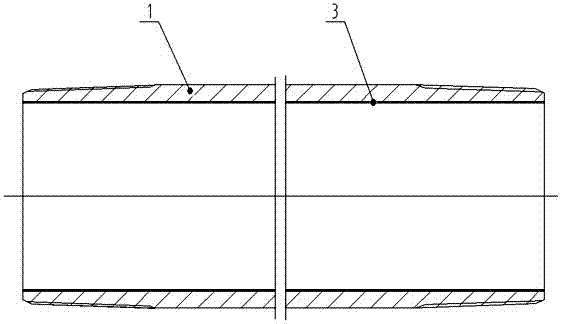

[0027] Reference figure 1 , The internal spray-welded anti-corrosion and wear-resistant pipe includes a pipe body 1 and an anti-corrosion and wear-resistant alloy layer 3 spray-welded on the inner hole wall of the pipe body 1. The processing method: clean the inner hole of the pipe body 1, spray-weld a layer of anti-corrosion and wear-resistant alloy 3 on the inner hole, and then process the threads, and connect with the ordinary coupling to form an anti-corrosion and wear-resistant oil pipe. This structured product has simple processing technology and low cost, and is suitable for oil wells with severe partial wear and less corrosiveness. Of course, the above-mentioned processing method is also suitable for the processing of deep-hole parts such as oil well pump barrel and long cylinder liner.

Embodiment 2

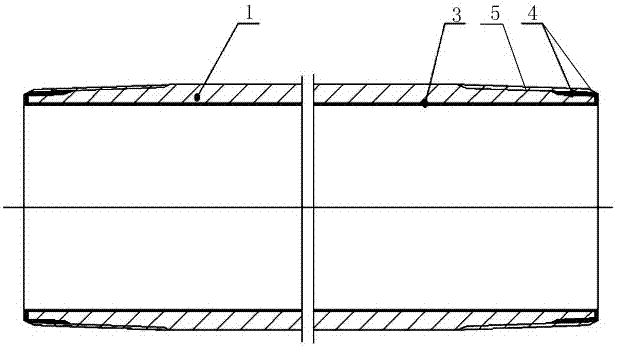

[0029] Such as figure 2 As shown, the processing technology: rough machining the end face and front end of the pipe body 1 (5mm-10mm from the end face), spray welding or surfacing the first corrosion-resistant alloy layer 4 at the rough machining part, clean the inner surface of the pipe body 1, and The surface of the hole is spray-welded with corrosion-resistant alloy layer 3 and threaded. Through the first corrosion-resistant alloy layer 4, the connection part of the pipe body 1 can be located here, which prevents the connection part from contacting corrosive liquid.

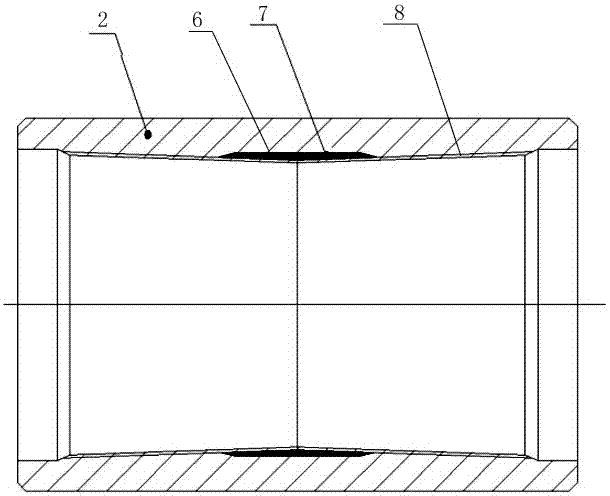

[0030] Such as image 3 As shown, a groove 6 is provided on the inner wall of the coupling 2, a second corrosion-resistant alloy layer 7 is sprayed or built-up welded in the groove 6, and the internal thread 8 is processed and connected.

[0031] Such as Figure 4 As shown, the pipe body 1 and the coupling 2 can be connected by connecting the external thread 5 and the connecting internal thread 8, and since their ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com