Local granule reinforced piston and its manufacture method

A particle reinforcement and piston technology, which is applied to pistons, machines/engines, mechanical equipment, etc., can solve the problems of local reinforcement parts falling off, rapid performance changes, complex process, etc., to achieve low manufacturing cost, increase wear resistance, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

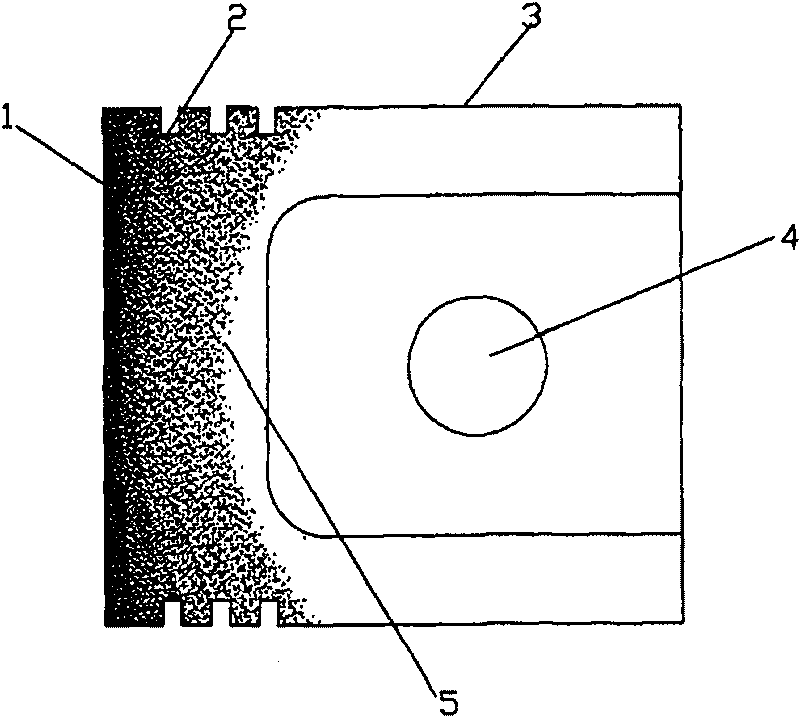

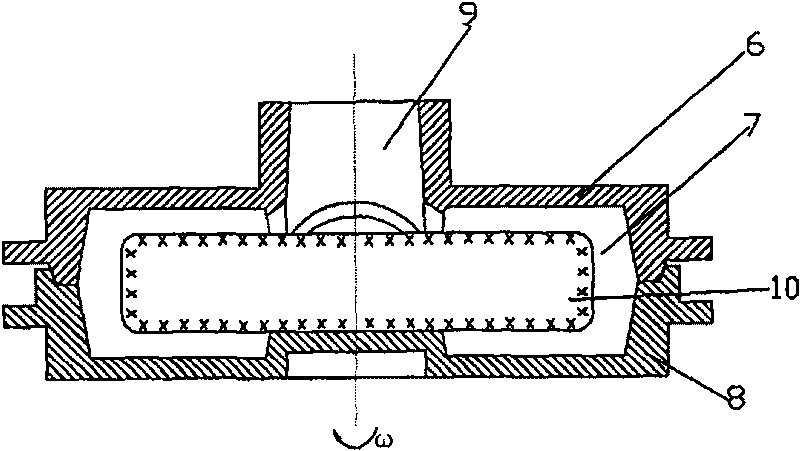

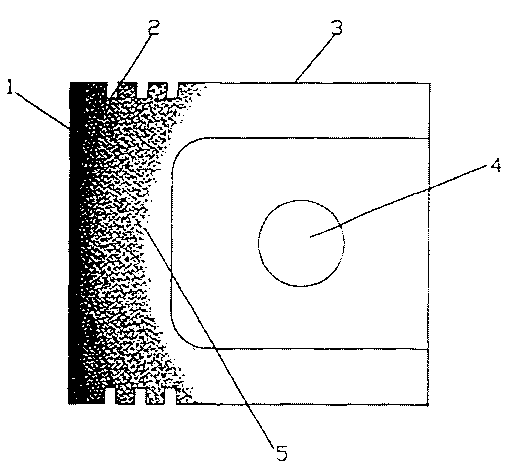

[0023] The reinforcement particles at the interface between the reinforcement region and the transition layer are greater than or equal to 10% by volume; the reinforcement particles are SiC ceramic reinforcement particles with a particle size of 10-50 μm, and the piston base material is aluminum or aluminum-based alloy.

Embodiment 2

[0025] The reinforcing particles at the interface between the reinforcing region and the transition layer are 20% by volume; the reinforcing particles are SiC ceramic reinforcing particles with a particle size of 10-50 μm, and the volume percent of reinforcing particles at the interface between the reinforcing region and the transition layer in this embodiment is The thermal expansion performance of the reinforced area of the piston, the wear resistance and the overall tensile performance of the piston are better than those of the first embodiment.

Embodiment 3

[0027] The reinforcing particles at the interface between the reinforcing area and the transition layer are 25% by volume; the reinforcing particles are SiC ceramic reinforcing particles with a particle size of 10-50 μm, and the volume percentage of the reinforcing particles at the interface between the reinforcing area and the transition layer in this embodiment is The thermal expansion performance of the reinforced area of the piston, the wear resistance and the overall tensile performance of the piston are better than those of the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com