Installation and construction method of assembly type house building composite slabs

A construction method and technology of laminated board, applied in the direction of building, building components, building structure, etc., can solve the problems of reducing the tensile capacity of anchoring steel bars, the overall instability of beam steel bars, affecting the quality of the structure, etc., so as to shorten the construction period and achieve tight connection , to ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

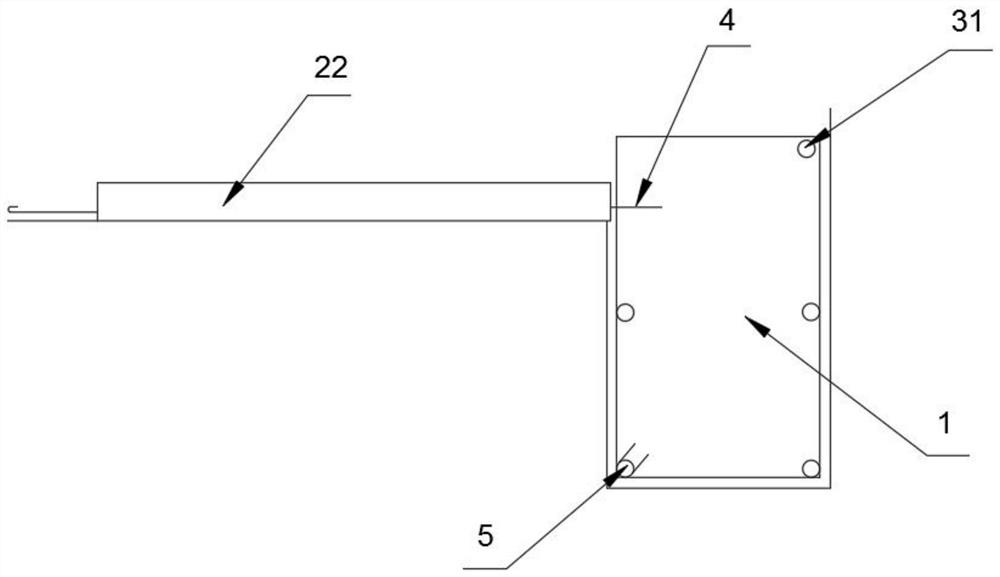

[0042] like figure 1 As shown, a prefabricated building construction method for installing laminated panels, when only one side of the beam 1 needs to be provided with laminated panels, includes the following steps:

[0043] Step 1: Binding the steel bars of the beam 1, temporarily fixing the first upper steel bar 31 of the beam 1 on the first side of the upper part of the beam 1, and setting the stirrup hook 5 at the bottom of the beam 1 or on the first side of the upper part of the beam 1;

[0044] Step 2: hoisting the second laminated plate 22 on the second side of the upper part of the beam 1, the first side and the second side are respectively located on both sides of the beam 1;

[0045] Step 3: Restoring the temporarily fixed first upper steel bar 31 and then fixing and binding it.

[0046] The first upper steel bar 31 is a corner bar.

[0047] Since the first upper reinforcement bar 31 and the second laminated plate 22 are located on different sides of the upper part...

Embodiment 2

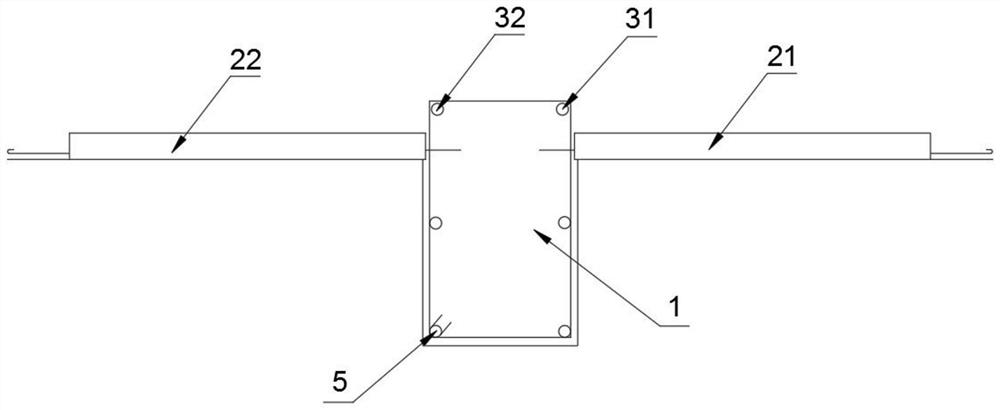

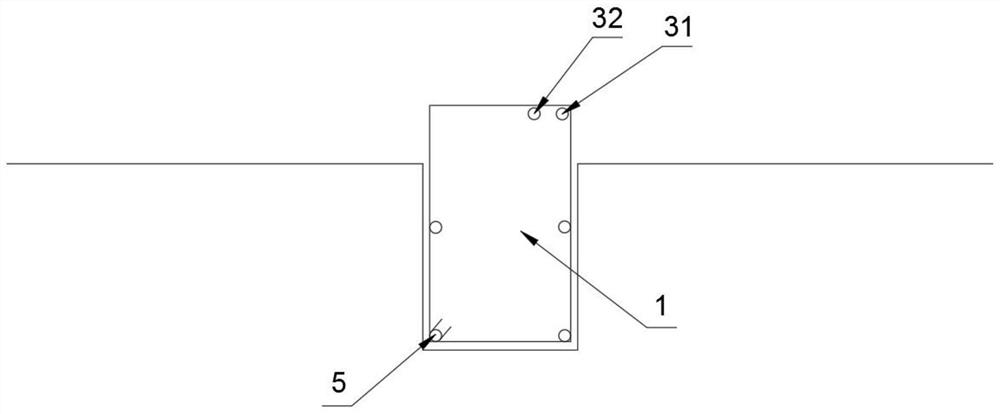

[0049] like Figure 2-Figure 7 As shown, a prefabricated building construction method for installing laminated panels, when the laminated panels are provided on both sides of the beam 1, includes the following steps:

[0050] Step 1: Temporarily fix the first upper steel bar 31 and the second upper steel bar 32 of the beam 1 on the first side of the upper part of the beam 1, and set the stirrup hook 5 at the bottom of the beam 1;

[0051] Step 2: hoisting the second laminated plate 22 on the second side of the upper part of the beam 1, the first side and the second side are respectively located on both sides of the beam 1;

[0052] Step 3: remove the first upper reinforcing bar 31 and the second upper reinforcing bar 32, temporarily fix the first upper reinforcing bar 31 on the second side of the upper part of the beam 1, and fix and bind the second upper reinforcing bar 32 on the second side of the upper part of beam 1;

[0053] Step 4: hoisting the first laminated plate 21 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com