Current collector etched foil and preparation method thereof, electrode and lithium battery

A technology for current collectors and lithium batteries, applied in the direction of electrode carriers/collectors, secondary batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of increased electrode interface impedance, powdered electrode materials, and battery performance degradation The effect of increased force, increased mechanical flexibility, and light weight ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

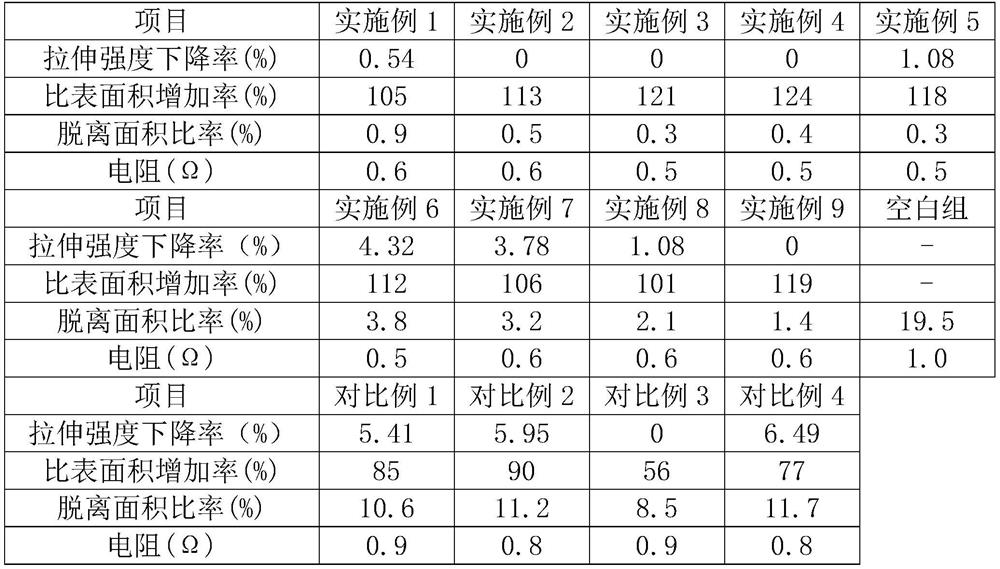

Examples

preparation example Construction

[0027] The application provides a preparation method of a current collector etched foil, comprising the following steps:

[0028] S1. Provide metal foil;

[0029] In the present application, the thickness of the metal substrate is preferably 10 to 20 μm. In other embodiments of the present application, the thickness of the metal substrate may also be less than 10 μm or greater than 20 μm.

[0030] The metal substrate of the present application is aluminum foil or copper foil, but is not limited thereto. Due to the serious corrosion problem of aluminum foil at low potential, it is mainly used for positive current collectors. Among them, the impure composition of aluminum foil will cause the surface oxide film to be not dense and cause pitting corrosion, and even LiAl alloy will be formed.

[0031] In order to effectively remove impurities, oil stains and oxide layers on the aluminum foil or copper foil, improve the cleanliness and surface wetting tension of the current collec...

Embodiment 1

[0064] A preparation method of a current collector etched foil, comprising the following steps:

[0065] S1. Provide an aluminum foil substrate with a thickness of 12 μm;

[0066] S2. The unwinding machine is used to release the rolled aluminum foil substrate to the tension roller, and the aluminum foil substrate is transported to the pickling tank, alkali cleaning tank, pickling tank and Cleaning tank; wherein, the pickling solution in the pickling tank includes 1.1wt% HF and 2.9wt% H 2 SO 4 , the alkaline washing solution in the alkaline washing tank includes 0.8wt% Ca(OH) 2 and 3.2wt% LiOH, the cleaning tank contains deionized water at a temperature of 50 °C;

[0067] S3, drying the aluminum foil substrate at a speed of 130 m / min after the etching process in step S2 at 130° C. to obtain a current collector etched aluminum foil.

Embodiment 2

[0069] A preparation method of a current collector etched foil, comprising the following steps:

[0070] S1. Provide an aluminum foil substrate with a thickness of 12 μm;

[0071] S2. The unwinding machine is used to release the rolled aluminum foil substrate to the tension roller, and the aluminum foil substrate is transported to the pickling tank, alkali cleaning tank, pickling tank and Cleaning tank; wherein, the pickling solution in the pickling tank includes 1.2wt% HF and 3.3wt% H 2 SO 4 , the alkaline washing solution in the alkaline washing tank includes 1wt% Ca(OH) 2 and 3.5wt% LiOH, the cleaning tank contains deionized water at a temperature of 55 °C;

[0072] S3, drying the aluminum foil base material after the etching treatment in step S2 at 140° C. to obtain a current collector etched aluminum foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com