Plasma treatment method for corrosion-proof turbine molecular pump blade

A turbomolecular pump and plasma technology, which is applied to the components, pumps, and pump components of the pumping device for elastic fluids, can solve the problems of affecting the mechanical strength of aluminum alloy blades, being easily corroded, damaged, etc. The effect of clean and environmentally friendly process, strong corrosion resistance and simple treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

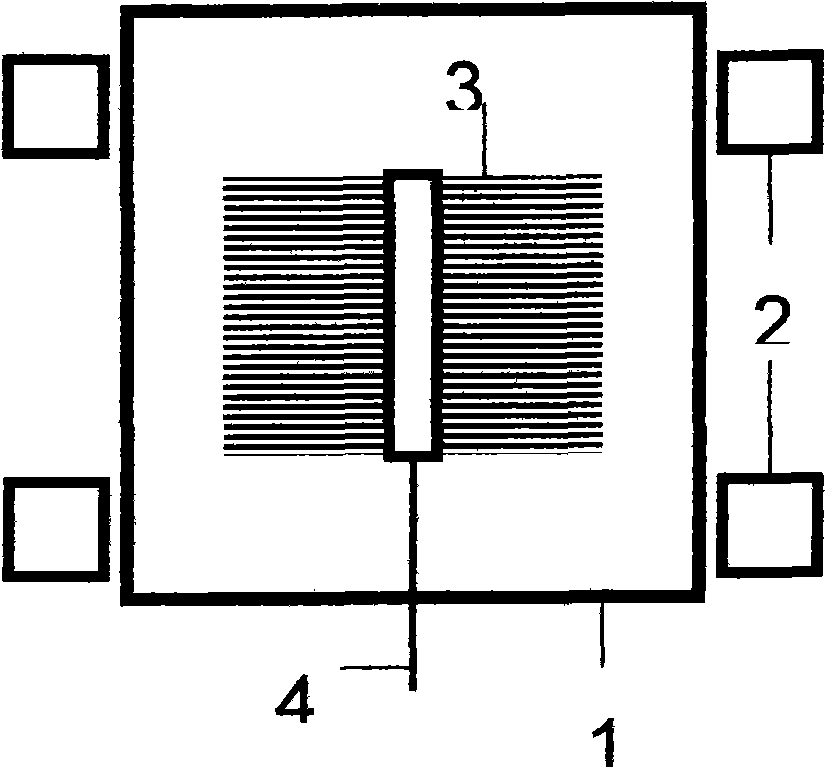

[0023] Using CCP plasma processing device, put the blade of the molecular pump into figure 1 In the vacuum chamber 1 shown, after the background vacuum in the vacuum chamber is evacuated to less than 1 Pa, 99.99% high-purity Ar is introduced at 100 sccm, and the pressure is maintained at 10 Pa, and the electromagnetic coil 2 outside the vacuum chamber 1 is added Electric current, the electromagnetic field generated is kept at 100 Gauss, and 800W of radio frequency power is applied to the blade 3 through the electrode 4 for 5 minutes, so that the surface of the blade is cleaned;

[0024] Then oxygen gas is introduced into the vacuum chamber 1, the flow of argon is adjusted to 10sccm, the flow of oxygen is 50sccm, the air pressure in the vacuum chamber is maintained at 50Pa, the RF power is 400W, the blade temperature is controlled at 400℃, after treatment for 3 hours, natural cooling Take it out to room temperature, so that about 30μm of aluminum oxide will be formed on the surfac...

Embodiment 2

[0026] Using CCP plasma processing device, put the blade of the molecular pump into figure 1 In the vacuum chamber 1 shown, after the background vacuum in the vacuum chamber is pumped to less than 1 Pa, 99.99% high-purity Ar is introduced at 100 sccm, the pressure is maintained at 10 Pa, and the electromagnetic coil 2 outside the vacuum chamber 1 is applied with current. To keep the generated electromagnetic field at 200 Gauss, add 800W of RF power to the blade 3 through the electrode 4 for 5 minutes to clean the surface of the blade;

[0027] Then pass nitrogen into the vacuum chamber 1, adjust the flow of argon to 10sccm, the flow of nitrogen to 100sccm, keep the air pressure at 30Pa, the RF power at 500W, and the blade temperature at 400℃. After treatment for 2 hours, cool to room temperature and take it out. In this way, aluminum nitride with a thickness of about 20μm will be formed on the surface of the aluminum alloy blade, which can play a role in corrosion resistance.

Embodiment 3

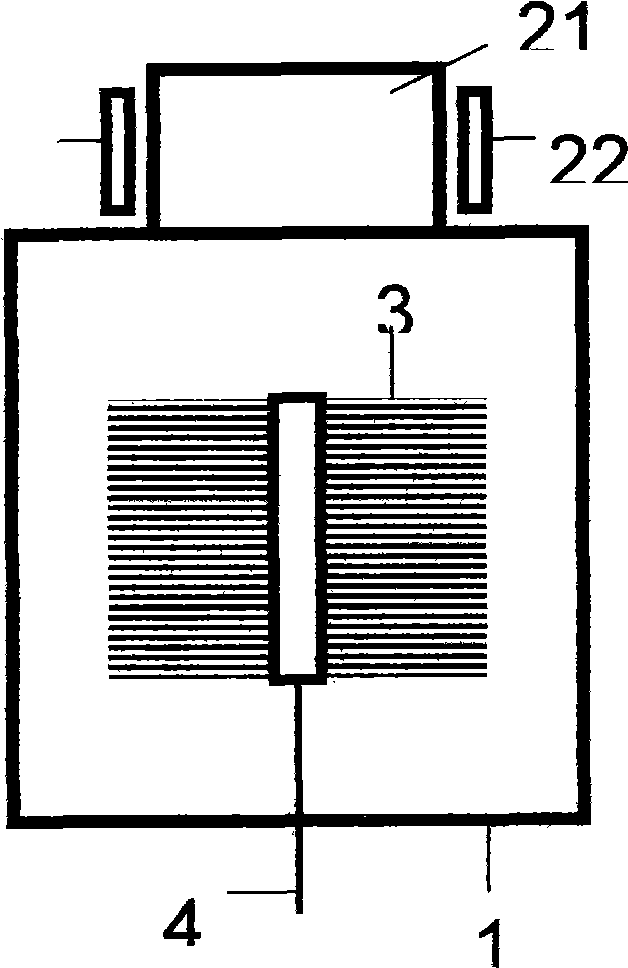

[0029] Using ICP plasma processing device, put the blade of the molecular pump into figure 2 In the vacuum chamber 1 shown, after the background vacuum of the vacuum chamber is evacuated to less than 1 Pa, 99.99% high-purity Ar is introduced at 50 sccm, the pressure is controlled at 5 Pa, and the coil 22 is placed outside the quartz window 21 through the radio frequency power supply. Apply 500W of radio frequency power, apply a negative bias voltage of 200V to the blade 3 through the electrode 4, and keep it for 5 minutes, so that the surface of the blade is cleaned;

[0030] Then pass oxygen at 50sccm into the vacuum chamber, the oxygen flow is 50sccm, the argon flow is adjusted to 5sccm, the air pressure is maintained at 5Pa, the RF power is adjusted to 400W, the blade temperature is controlled at 300℃, the negative bias voltage is 50V, and the treatment is 2 hours After that, it is naturally cooled to room temperature and taken out. In this way, aluminum oxide with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com