Permeation corrosion inhibition type rusty antirust primer and preparation method and application thereof

A rust-proof and primer technology, applied in primers, anti-corrosion coatings, coatings, etc., can solve the problems of difficult to meet the actual needs of anti-corrosion life, poor corrosion inhibition ability, and insufficient quality of anti-corrosion engineering.

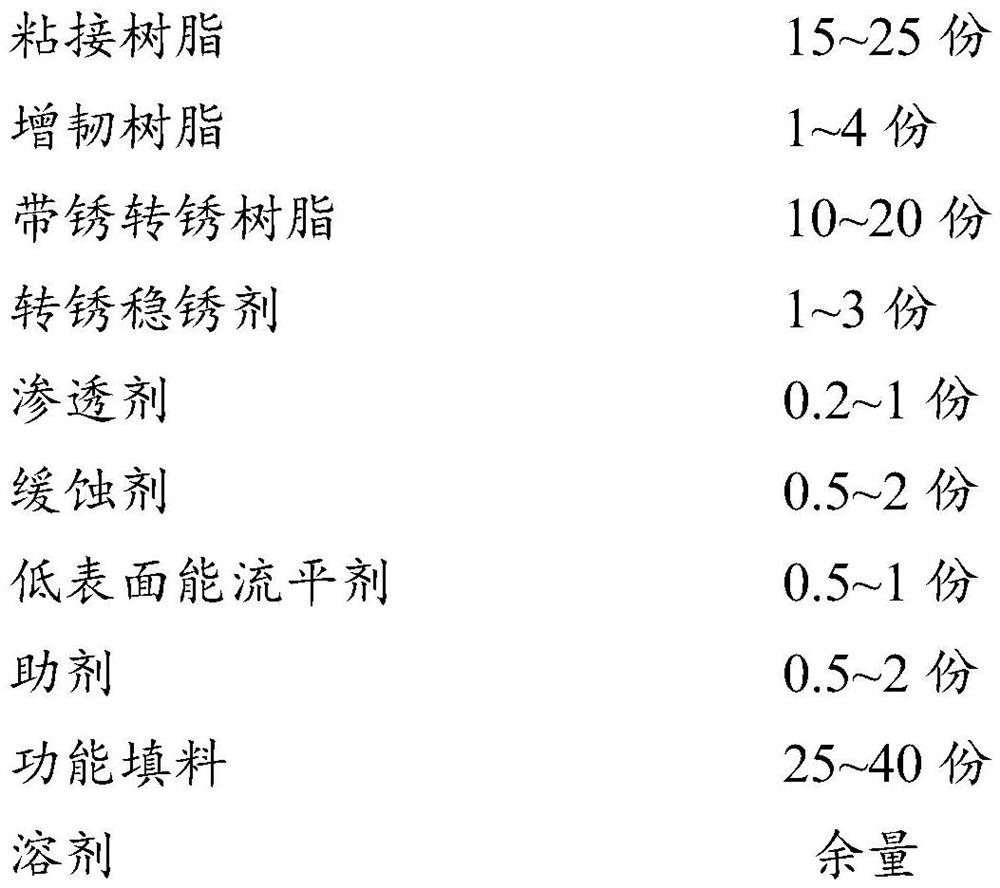

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

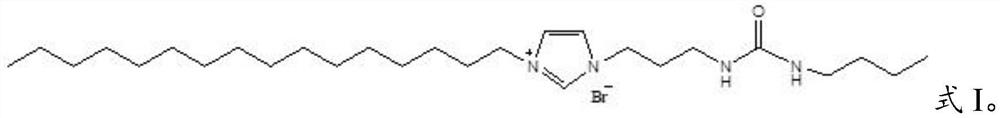

[0059] In the dispersion tank, add 20.5 parts by mass of Nanya 901 epoxy resin, 2 parts by mass of 102C-4L polyurethane modified epoxy resin, 16 parts by mass of X800-1 rust-reversing resin with rust, 14 parts by mass of xylene, 6 parts by mass of normal Butanol, 6 parts by mass of ethanol, mix well; add 0.8 parts by mass of low surface energy leveling agent AC-8700, 0.25 parts by mass of Tiger 386N defoamer, 0.5 parts by mass of BYK104S wetting and dispersing agent, 0.25 parts by mass of BYK410 anti-settling Thixotropic agent, stir and disperse at a speed of 300r / min for 30min; add 2 parts by mass of diphenylguanidine chromate, 0.5 parts by mass of docusate sodium, 1 part by mass of high-performance corrosion inhibitor M16, 14.2 parts by mass of iron oxide red, 5 Parts by mass of zinc phosphate, 5 parts by mass of aluminum tripolyphosphate, 5 parts by mass of sericite, and 1 part by mass of organic bentonite, stirred and dispersed at a speed of 300r / min for 30 minutes, then gr...

Embodiment 2

[0063] In the dispersion tank, add 21 parts by mass of Nanya 901 epoxy resin, 2.1 parts by mass of 102C-4L polyurethane modified epoxy resin, 16.6 parts by mass of X800-1 rust-removing resin with rust, 13 parts by mass of xylene, 6 parts by mass of normal Butanol, 6 parts by mass of ethanol, mix well; add 0.9 parts by mass of low surface energy leveling agent AC-8700, 0.25 parts by mass of Tiger 386N defoamer, 0.5 parts by mass of BYK104S wetting and dispersing agent, 0.25 parts by mass of BYK410 anti-settling Thixotropic agent, stir and disperse at a speed of 300r / min for 30min; add 2.1 parts by mass of diphenylguanidine chromate, 0.5 parts by mass of docusate sodium, 0.8 parts by mass of high-performance corrosion inhibitor M16, 14 parts by mass of iron oxide red, 5 Parts by mass of zinc phosphate, 5 parts by mass of aluminum tripolyphosphate, 5 parts by mass of sericite, and 1 part by mass of organic bentonite, stirred and dispersed at a speed of 300r / min for 30 minutes, the...

Embodiment 3

[0067] In the dispersion tank, add 20 parts by mass of Nanya 901 epoxy resin, 2 parts by mass of linear SBS resin, 17 parts by mass of X800-1 rust-removing resin with rust, 14 parts by mass of xylene, 6 parts by mass of n-butanol, 6 parts by mass of Parts of ethanol, mix well; add 0.8 parts by mass of low surface energy leveling agent BYK333, 0.25 parts by mass of Tiger 386N defoamer, 0.5 parts by mass of BYK104S wetting and dispersing agent, 0.25 parts by mass of BYK410 anti-sedimentation thixotropic agent, at 300r / Min speed stirring dispersion 30min; Add 2.5 parts by mass of diphenylguanidine chromate, 0.5 parts by mass of docusate sodium, 1.2 parts by mass of high-performance corrosion inhibitor M16, 13 parts by mass of iron oxide red, 5 parts by mass of zinc phosphate, 5 parts by mass of 1 part of aluminum tripolyphosphate, 5 parts by mass of sericite, 1 part by mass of organic bentonite, stirred and dispersed at a speed of 300 r / min for 30 minutes, then ground to a finene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com