Decorative lamp tinting processing method

A processing method and a technology for decorating lamps, which are applied to components of lighting devices, lighting devices, non-electric lighting devices, etc., can solve the problems of long processing cycle, cumbersome process, and high cost, so as to simplify the surface treatment process and reduce costs , Improve the effect of surface treatment quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Make a decorative lamp with a silver frame and a white decorative patch:

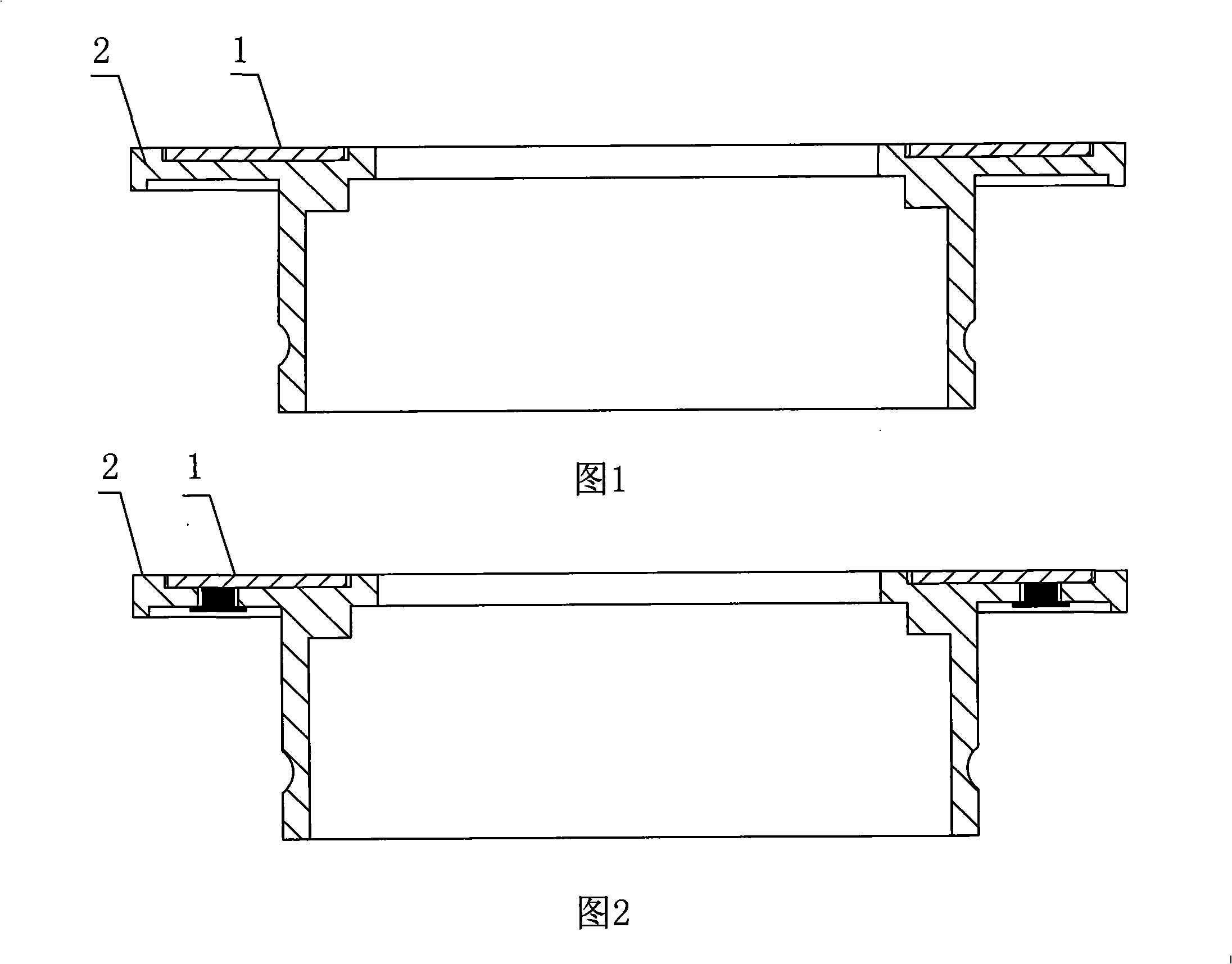

[0012] 1) Perform silver electroplating surface treatment on the finished lamp holder, the process steps are: lamp holder surface polishing - degreasing and rust removal - washing - perchromic acid - washing - passivation - washing - drying - silver electroplating;

[0013] 2) Carry out the white spraying treatment process on the prepared decorative surface, the process steps are: cleaning, degreasing, rust and decontamination of the decorative surface-drying-spraying white material;

[0014] 3) Adhering the light frame and the decorative surface sheet after the above steps 1) and 2) with an adhesive, to obtain a colorful decorative lamp with the decorative surface 1 being white and the light frame 2 being silver (see Figure 1).

Embodiment 2

[0016] Make a decorative lamp with a gold frame and a silver trim:

[0017] 1) Carry out gold electroplating surface treatment on the prepared lamp holder, the process steps are: lamp holder surface polishing - degreasing and rust removal - washing - perchromic acid - washing - passivation - washing - drying - electroplating gold material;

[0018] 2) Perform silver electroplating surface treatment on the prepared decorative surface. The process steps are: surface polishing of decorative surface - degreasing and rust removal - water washing - perchromic acid - water washing - passivation - water washing - drying - electroplating silver material;

[0019] 3) Correspondingly riveting and affixing the lamp holder and the decorative surface after the above steps 1) and 2) to obtain a colorful decorative lamp with the decorative surface 1 being silver and the lamp holder 2 being golden (see Figure 2). Show).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com