Process for treating surface of austenitic stainless steel equipment at normal temperature

A technology for austenitic stainless steel and equipment, which is applied in the field of anti-corrosion treatment process for the surface of austenitic stainless steel equipment. the effect of the requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

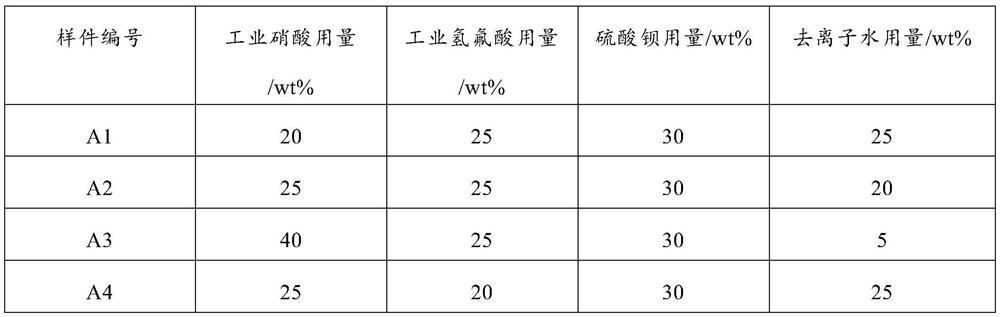

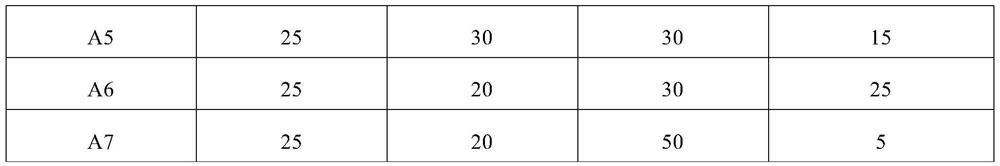

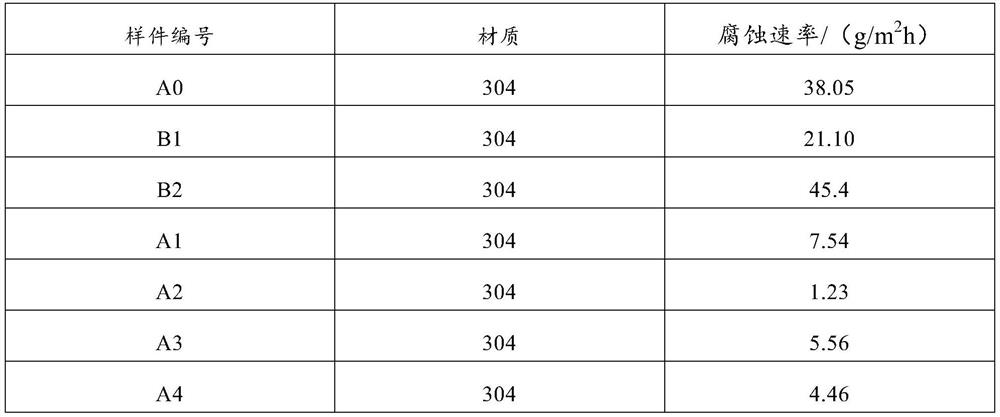

[0032] Embodiment 1: Acidification ointment formula optimization experiment

[0033] The product specification of 304 workpiece: 0.2*50*50mm (thickness*length*width), the residual martensite on the surface is 4.05%. The formula of acidifying cream is shown in Table 1. The experimental method is as follows:

[0034] (1) brushing the acidifying paste of formula shown in table 1 to the thickness of 2mm on the surface of 304 workpieces, carrying out acidizing treatment for 80 minutes, then washing with water for 3 minutes;

[0035] (2) Then carry out brush plating to the workpiece after step (1) processing, 304 workpieces are connected power supply negative pole, brush plating pen is connected power supply positive pole, and the brush plating nib adopts graphite material outsourcing anode cloth; Brush plating liquid composition comprises CrO 3 100g / L, Na 2 MoO 4 100g / L, H 3 PO 4 200g / L; brush plating current density 600A / m2 , When brush plating, put the brush plating hea...

Embodiment 2

[0040] Embodiment 2: acidification process parameter optimization experiment

[0041] The product specification of 304 workpiece: 0.2*50*50mm (thickness*length*width), the residual martensite on the surface is 4.05%. Acidification was carried out according to the process parameters shown in Table 2. The experimental method is as follows:

[0042] (1) brushing the acidifying paste consisting of 25% industrial nitric acid, 25% industrial hydrofluoric acid, 30% barium sulfate and 20% deionized water to the surface of 304 workpieces for acidification, and then washing for 3 minutes;

[0043] (2) Then carry out brush plating to the workpiece after step (1) processing, 304 workpieces are connected power supply negative pole, brush plating pen is connected power supply positive pole, and the brush plating nib adopts graphite material outsourcing anode cloth; Brush plating liquid composition comprises CrO 3 100g / L, Na 2 MoO 4 100g / L, H 3 PO 4 200g / L; brush plating current d...

Embodiment 3

[0047] Embodiment 3: brush plating process parameter optimization experiment

[0048] The product specification of 304 workpiece: 0.2*50*50mm (thickness*length*width), the residual martensite on the surface is 4.05%. The experimental method is as follows:

[0049] (1) Brush the acidizing paste consisting of 25% industrial nitric acid, 25% industrial hydrofluoric acid, 30% barium sulfate and 20% deionized water to a thickness of 2mm on the surface of the 304 workpiece, and carry out acidizing treatment for 80 minutes , then wash with water for 3 minutes;

[0050] (2) Then the 304 workpiece is connected to the negative pole of the power supply, the brush plating pen is connected to the positive pole of the power supply, and the brush plating pen head is made of graphite material to outsource the anode cloth; the composition of the brush plating solution includes CrO 3 100g / L, Na 2 MoO 4 100g / L, H 3 PO 4 200g / L; Carry out brush plating according to the parameter shown ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com