Carbon fiber/polyphenylene sulfide composite material and preparation method and application thereof

A polyphenylene sulfide and composite material technology, applied in the direction of additive processing, etc., can solve the problems of inability to accurately control the uniform content of carbon fibers, low bonding force between layers of printed parts, and complicated surface treatment of carbon fibers, and achieve low shrinkage. Mechanical properties, easy preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] One aspect of the embodiments of the present invention provides a method for preparing a carbon fiber / polyphenylene sulfide composite material, which includes:

[0027] Carry out surface pretreatment to carbon fiber to obtain pretreated carbon fiber;

[0028] Uniformly mixing the pretreated carbon fiber, carrier, dispersant and solvent and performing granulation treatment to obtain carbon fiber masterbatch;

[0029] And, uniformly mixing the carbon fiber masterbatch, polyphenylene sulfide, toughening agent and antioxidant, and then performing granulation treatment again to obtain a carbon fiber / polyphenylene sulfide composite material.

[0030] In some more specific embodiments, the mass ratio of the carbon fiber masterbatch, polyphenylene sulfide, toughening agent and antioxidant is (5~25):(65~90):(3~5):(2 ~5).

[0031] Further, the toughening agent includes ethylene-octene copolymer (POE), styrene-butadiene thermoplastic elastomer (SBS), acrylonitrile-butadiene-styr...

Embodiment 1

[0059] (1) Treat the carbon fiber (the length of the carbon fiber is 100 mesh) by plasma surface treatment technology for 10 minutes, and then use γ-aminopropyltriethoxysilane to carry out grafting treatment to obtain the pretreated carbon fiber;

[0060] (2) Mix the pretreated carbon fiber obtained in step (1), PEG-2000, sodium dodecylbenzene sulfonate and water to form a slurry, then dry the obtained slurry to a paste, and then use a single screw to make Granulator for granulation to produce carbon fiber masterbatch;

[0061] (3) Mix the carbon fiber masterbatch, polyphenylene sulfide (PPS pellets), ethylene-octene copolymer, and antioxidant 1010 in a mass ratio of 5:80:4:4, and input them into a twin-screw extruder Carry out mixing and granulation to obtain a carbon fiber / polyphenylene sulfide composite material for 3D printing;

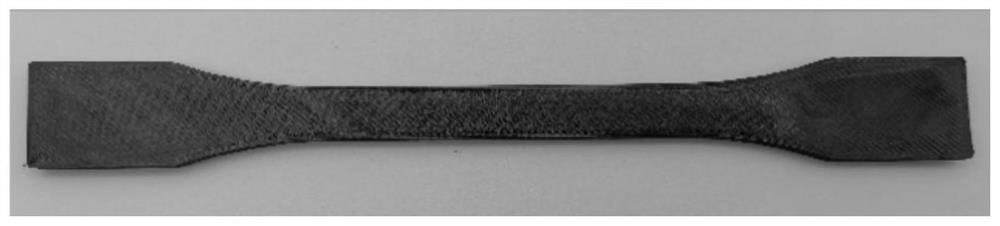

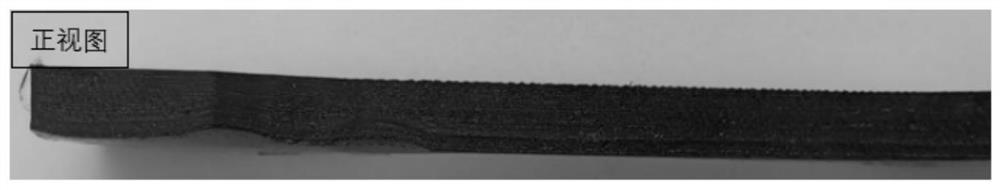

[0062] (4) Input the carbon fiber / polyphenylene sulfide composite material for 3D printing into a single-screw extruder for hopper extrusion, wi...

Embodiment 2

[0064] The method is the same as in Example 1, except that the mass ratio of carbon fiber masterbatch, polyphenylene sulfide (PPS pellets), toughening agent, and antioxidant is 10:80:4:4; the mechanical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com