Semi-integral safety box and manufacturing method thereof

A semi-integral, safe technology, applied in safes, building structures, buildings, etc., can solve the problems of affecting the service life of safes, the overall strength of safes, and the deformation of safe boxes, so as to avoid the decline of overall strength , Eliminate welding and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

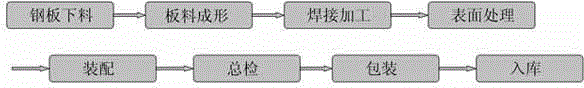

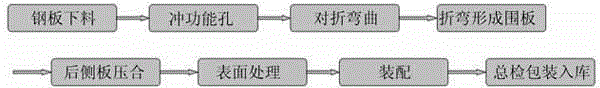

[0045] Such as Figure 3-5 Shown, a kind of manufacturing method of semi-integral safe, this method comprises the steps:

[0046] (1) Steel plate blanking: use the first press 12 and the blanking mold to blank the steel coil 7 to form a steel plate blank, the thickness of the steel plate is 6mm, the material of the steel plate is 304 stainless steel, and the steel plate is made of steel The coil 7 is formed by uncoiling and blanking by the uncoiler 8. Before uncoiling, the steel coil is subjected to surface brightening treatment. After the steel coil 7 is uncoiled by the uncoiler 8, it bypasses the tension wheel 9 and enters the protective film covering machine 10. The steel coil passes through the protective film. The covering machine 10 covers the surface of the steel coil with a layer of protective film, and the steel coil covered with the protective film enters the first press 12 for stamping and blanking to form a steel plate blank;

[0047](2) Punching functional holes:...

Embodiment 2

[0055] Such as Figure 3-5 Shown, a kind of manufacturing method of semi-integral safe, in this embodiment, the difference compared with embodiment 1 is: the steel plate thickness that adopts is 4mm, and the material of steel plate is Q460 high-strength steel plate, because thickness is thinner, in steel coil Before entering the stamping blanking, it is straightened by a straightener 11.

[0056] The method comprises the steps of:

[0057] (1) Steel plate blanking: Use the first press 12 and the blanking mold to blank the steel coil 7 to form a steel plate blank. The thickness of the steel plate is 4 mm. The steel plate is formed by uncoiling and blanking the steel coil 7 through the uncoiler 8 , before uncoiling, the steel coil is subjected to surface brightening treatment. After the steel coil 7 is uncoiled by the uncoiler 8, it bypasses the tension wheel 9 and enters the protective film covering machine 10. The steel coil passes through the protective film covering machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com