Technology for surface treatment of double-layered stainless steel product

A surface treatment and stainless steel technology, which is applied in the surface treatment process of double-layer stainless steel products and the field of stainless steel products, can solve the problems of destroying the vacuum effect of the products, the appearance is dull and dull, and the cost is high, so as to achieve reasonable preparation, clean surface and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

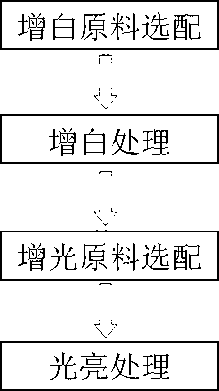

Image

Examples

Embodiment 1

[0015] The specific implementation steps are as follows:

[0016] a) Selection of whitening raw materials. The whitening raw materials selected for the surface treatment of the double-layer stainless steel products include: 400g / L sodium hydroxide solution, 80g / L nitric acid with a concentration of 63%, and 100g / L hydrofluoric acid with a concentration of 40%. , a concentration of 98% phosphoric acid 130g / L, a pickling corrosion inhibitor with a weight ratio of 0.1%; among them, the pickling corrosion inhibitor is a solid powder with stable performance, simple operation, small dosage, high efficiency, low cost, and no Toxic and odorless, no pollution to the environment; little corrosion to the metal substrate, high corrosion inhibition rate, safe to use.

[0017] b) Whitening treatment, whitening treatment includes the following steps: 1) Alkali washing treatment, the oxide film formed on the surface of the double-layer stainless steel product becomes loose after alkali washin...

Embodiment 2

[0021] The specific implementation steps are as follows:

[0022] a) Selection of whitening raw materials, the whitening raw materials selected for the surface treatment of the double-layer stainless steel products include: sodium hydroxide solution 500g / L, nitric acid with a concentration of 63% 120g / L, hydrofluoric acid with a concentration of 40% 150g / L , a concentration of 98% phosphoric acid 160g / L, a pickling corrosion inhibitor with a weight ratio of 0.2%; among them, the pickling corrosion inhibitor is a solid powder with stable performance, simple operation, small dosage, high efficiency, low cost, and no Toxic and odorless, no pollution to the environment; little corrosion to the metal substrate, high corrosion inhibition rate, safe to use.

[0023] b) Whitening treatment, the whitening treatment includes the following steps: 1) Alkali washing treatment, the oxide film formed on the surface of the double-layer stainless steel product becomes loose after alkali washin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com