Preparation method of multi-element high-concentration liquid fertilizer with stable performance

A liquid fertilizer and multi-element technology, applied in fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of affecting crop absorption, affecting product properties and performance, and reducing the labeling of element content, so as to improve absorption efficiency and not easily be absorbed by water. The effect of scouring and inhibiting transpiration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

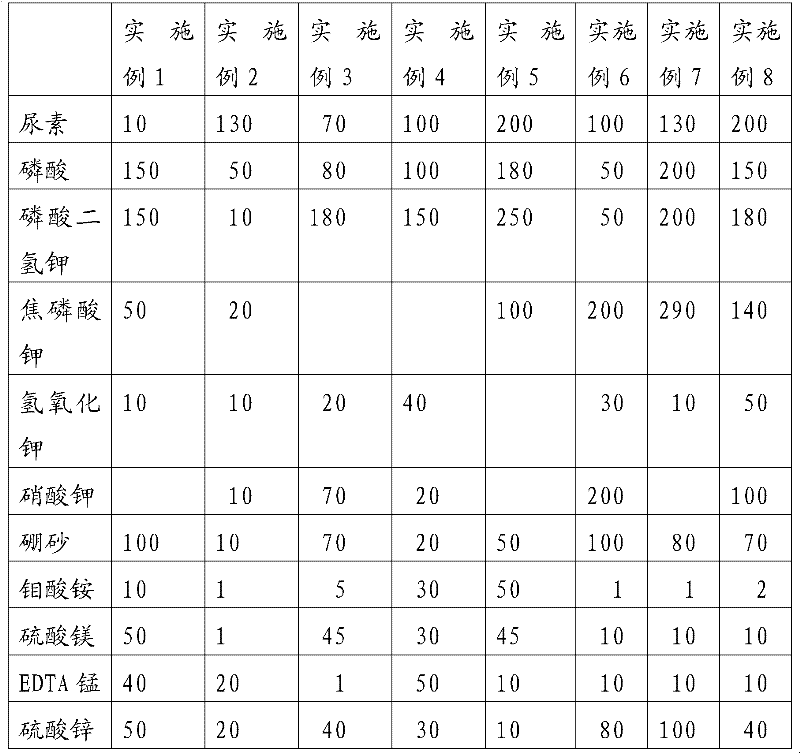

Examples

experiment example 1

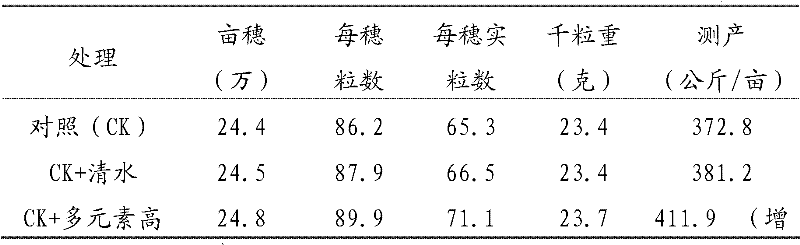

[0061] A early rice application multi-element high-concentration liquid fertilizer (embodiment 6) field fertilizer effect test

[0062] 1. Materials and methods

[0063] 1. Test fertilizer: the multi-element high-concentration liquid fertilizer obtained in Example 6.

[0064] 2. Test variety: conventional early rice "Zhong 86-44"

[0065] 3. Experimental design: There are three treatments in the experiment, namely:

[0066] Treatment ① customary fertilization (CK);

[0067] Treatment ② Habitual fertilization + spraying the same amount of water (CK + water);

[0068] Process 3. get used to fertilizing+spraying (CK+embodiment 6);

[0069] The experiment was repeated three times, the plots were randomly arranged, and the plot area was 2.5m×8m=20m 2

[0070] 4. Explanation of the experimental design: customary fertilization, which is the local average fertilization level, that is, 25 kg / mu of ammonium bicarbonate, 20 kg / mu of superphosphate, 5 kg / mu of potassium chloride, an...

experiment example 2

[0098] Effects of applying multi-element high-concentration liquid fertilizer on yield of A wheat at heading stage

[0099] The comparison test of different multi-element high-concentration liquid fertilizer spraying effects was arranged in the wheat experiment field of the students of the Department of Agronomy. The results showed that the multi-element high-concentration liquid fertilizer of the present invention can significantly increase the thousand-grain weight of wheat, which is 11.37% higher than that of the clean water control. , and also significantly increased the yield of wheat, which was 20.52% higher than that of the clear water control, but had no significant effect on the number of grains per panicle and the number of grains per mu. In this test, Green Fenway has no obvious effect on the traits.

[0100] 1. Materials and methods

[0101] 1.1 Crop varieties tested: Huamai 8910

[0102] 1.2 The ribs and application concentration of the tested foliar fertilizer:...

experiment example 3

[0123] 1. Basic conditions of the test

[0124] The experiment was carried out in Xiahuo Village, Jinshan Township, Tongcheng County. The soil type was gravel white mud field developed by river alluvial deposits, fluvo-aquic soil vegetable garden soil, and the soil fertility was medium. Adopt multi-element high-concentration liquid fertilizer (embodiment 8) to irrigate at the roots, and inject 5000ml of multi-element high-concentration liquid fertilizer into 500kg water successively per mu each time, be made into 1: 100 times of liquid, apply irrigation after mixing. Rapeseed has three groups: (1) clear water group: irrigate clear water once every 10 days; (2) experimental group: begin to irrigate and apply multi-element high-concentration liquid fertilizer (embodiment 8) at the root at the initial flowering stage, every 10 days Irrigate once again, repeat three times, the other time is the same as that of the water group, and irrigate with water once every 10 days: the dosage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com