Composite silver plating solution as well as preparation method thereof and electrodeposition process

A technology of electrodeposition and mixed solution, applied in the direction of electrolytic coating, coating, etc., can solve the problems of easy interface reaction, poor performance of silver-graphene composite coating, poor dispersion of graphene, etc., to achieve wear resistance and contact Improved properties such as resistance, low production equipment requirements, and good dispersion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

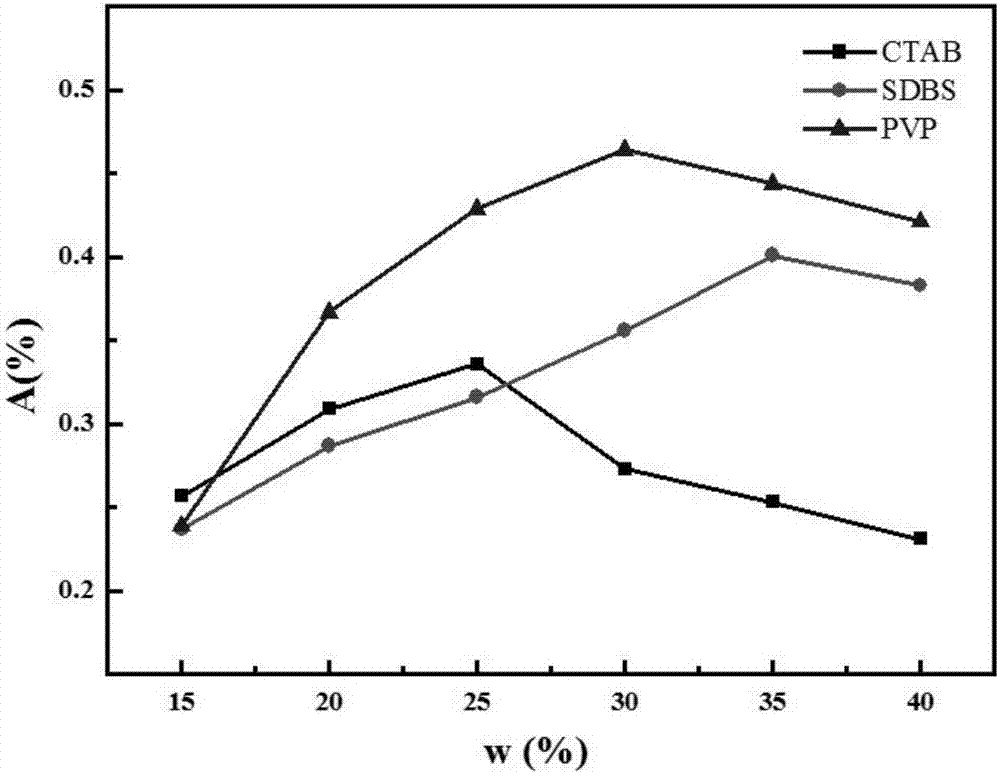

[0056] Test group 1: 1g / L graphene, PVP of 0.15~0.4g / L, make graphene-PVP aqueous solution, wherein, the mass percent of PVP in graphene-PVP aqueous solution is 15%, 20%, 25%, 30% %, 35%, 40%;

[0057] Test group 2: 1g / L graphene, 0.15~0.4g / L CTAB, prepared graphene-CTAB solution, wherein, the mass percentage of CTAB in the graphene-CTAB aqueous solution is 15%, 20%, 25%, 30% , 35%, 40%;

[0058] Test group 3: 1g / L graphene, 0.15~0.4g / L SDBS, make graphene-SDBS solution, make graphene-SDBS solution, wherein, the mass percentage of CTAB in graphene-SDBS aqueous solution is 15%, 20%, 25%, 30%, 35%, 40%.

[0059]The solutions of test group 1 to test group 3 were ultrasonically dispersed for 1 hour and then allowed to stand for 24 hours, then a certain amount of composite silver plating solution was taken, and the absorbance was measured by an ultraviolet spectrophotometer. The result is as figure 1 shown. From figure 1 It can be seen that the absorbance of the three graphen...

Embodiment 2

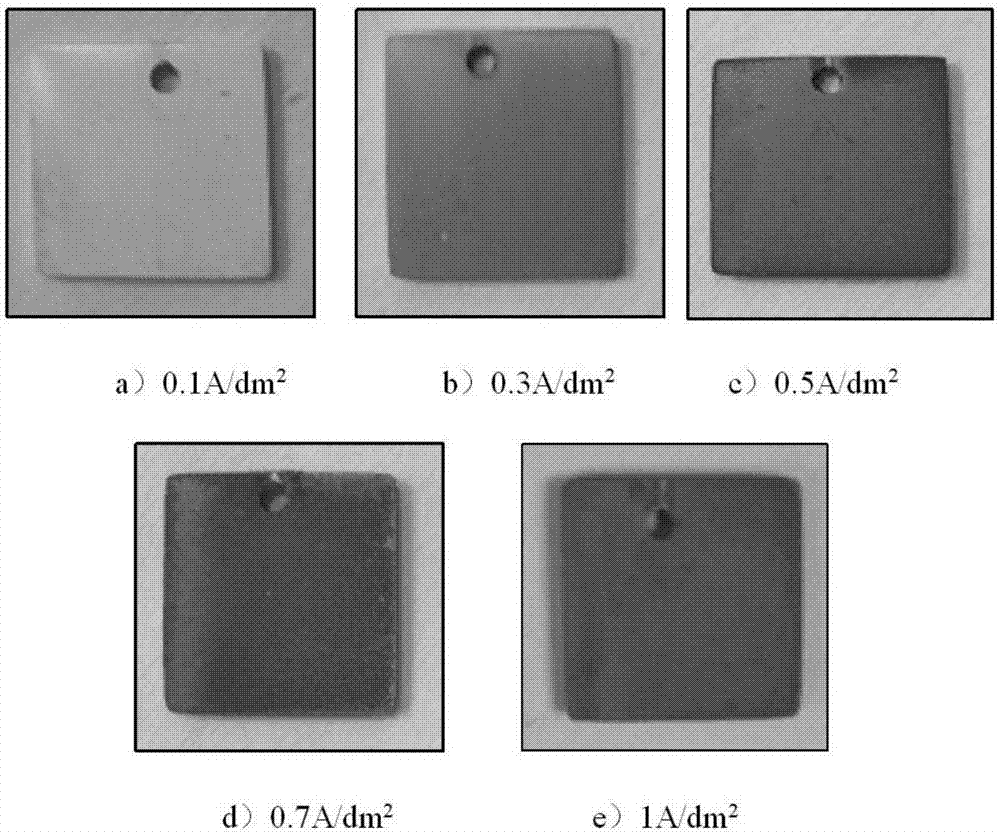

[0061] Test group 1 to test 5: 40g / L silver nitrate, 90g / L succinimide, 90g / L potassium pyrophosphate, 1g / L graphene, 0.3g / L PVP, potassium hydroxide: 40g / L, After fully stirring, sonicate for 1 h to prepare a composite silver plating solution.

[0062] After degreasing, grinding, ultrasonic cleaning, alkali cleaning and pickling, the copper substrate and silver sheet were placed in the composite silver plating solution of the above-mentioned test group 1 to test group 5, and then composite electrodeposition was carried out to prepare the silver-graphene composite plating.

[0063] The parameters of composite electrodeposition are set as:

[0064] Test group 1: current density: 0.1A / dm 2 ; Stirring speed: 1000r / min; Plating temperature: 40°C, electrodeposition time 60min;

[0065] Test group 2: current density: 0.3A / dm 2 ; Stirring speed: 1000r / min; Plating temperature: 40°C, electrodeposition time 60min;

[0066] Test group 3: current density: 0.5A / dm 2 ; Stirring speed...

Embodiment 3

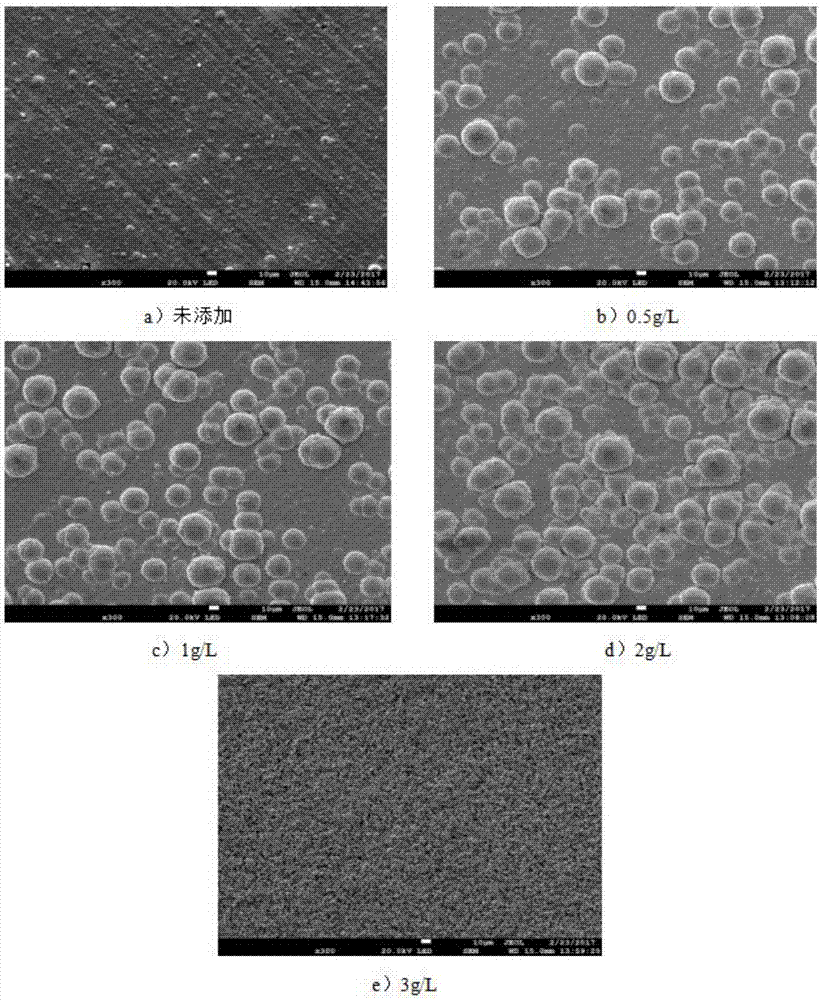

[0072] Wherein, the other parameters of the silver-graphene composite coating preparation process are kept unchanged, and the amount of graphene added is changed.

[0073] Test group 1: 40g / L silver nitrate, 90g / L succinimide, 90g / L potassium pyrophosphate, 0g / L graphene, 0g / L PVP, potassium hydroxide: 40g / L, to prepare composite silver plating solution;

[0074] Test group 2: 40g / L silver nitrate, 90g / L succinimide, 90g / L potassium pyrophosphate, 0.5g / L graphene, 0.15g / L PVP, potassium hydroxide: 40g / L, prepared Composite silver plating solution;

[0075] Experimental group 3: 40g / L silver nitrate, 90g / L succinimide, 90g / L potassium pyrophosphate, 1g / L graphene, 0.3g / L PVP, potassium hydroxide: 40g / L, the compound Silver plating solution;

[0076] Test group 4: 40g / L silver nitrate, 90g / L succinimide, 90g / L potassium pyrophosphate, 2g / L graphene, 0.6g / L PVP, potassium hydroxide: 40g / L, the compound Silver plating solution;

[0077] Test group 5: 40g / L silver nitrate, 90g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

| Absorbance | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com