Magnesium-lithium alloy surface electrocoppering solution and magnesium-lithium alloy surface electrocoppering treatment method

A magnesium-lithium alloy and electroplating copper technology, which is applied in the electroplating solution of magnesium-lithium alloy surface treatment, and in the field of electroplating copper treatment on the surface of magnesium-lithium alloy, can solve the problems of low efficiency and slow reaction rate, and achieve improved corrosion resistance and anti-corrosion. Corrosion improvement and speed improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The formula of copper plating solution is: copper pyrophosphate 60g / L; potassium pyrophosphate 300g / L; potassium dihydrogen phosphate 40g / L; potassium sodium tartrate 40g / L; citric acid 0.1g / L; Lansu 0.02g / L. Electroplating conditions: electroplating temperature is 30°C; current density is 1A / dm 2 ; pH is 9; electroplating time 30min.

[0033] Specific steps of electroplating copper process:

[0034] Grinding: Grinding the sample, grinding it with 320# and 1500# sandpaper, washing it frequently with distilled water during the grinding process, putting it into acetone for ultrasonic cleaning after grinding, and then drying it with cold air.

[0035] Alkali washing: mix 1g of NaOH, 1.5g of Na 3 PO 4 and 0.5g of Na 2 SiO 3 Add it into 50ml of distilled water, stir it and put it into a water bath at 60°C, then put the polished sample into it, time it for 10 minutes, take it out, wash it in hot water, and then put it into cold distilled water for ultrasonic cleaning ....

Embodiment 2

[0045] The formula of copper plating solution is: copper pyrophosphate 60g / L; potassium pyrophosphate 300g / L; potassium dihydrogen phosphate 40g / L; potassium sodium tartrate 40g / L; citric acid 0.1g / L; Lansu 0.02g / L. Electroplating conditions: electroplating temperature is 40°C; current density is 1A / dm 2 ; pH is 9; electroplating time 40min.

[0046] The specific steps of the copper electroplating process are the same as those in Example 1, except that the copper electroplating temperature is 40° C. and the plating time is 40 minutes.

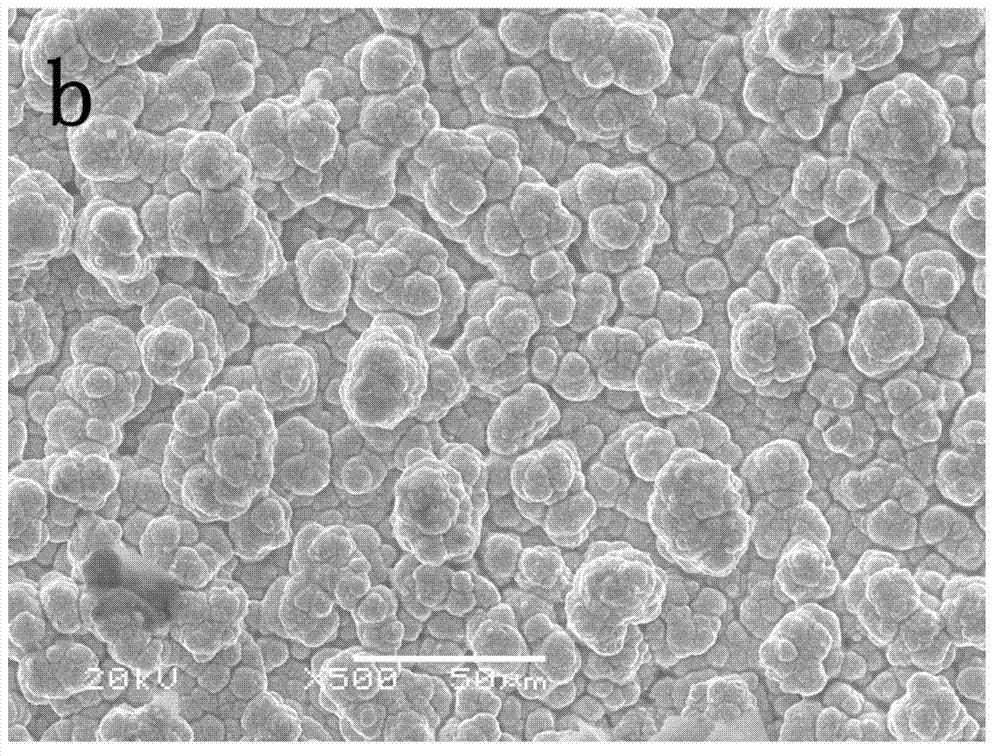

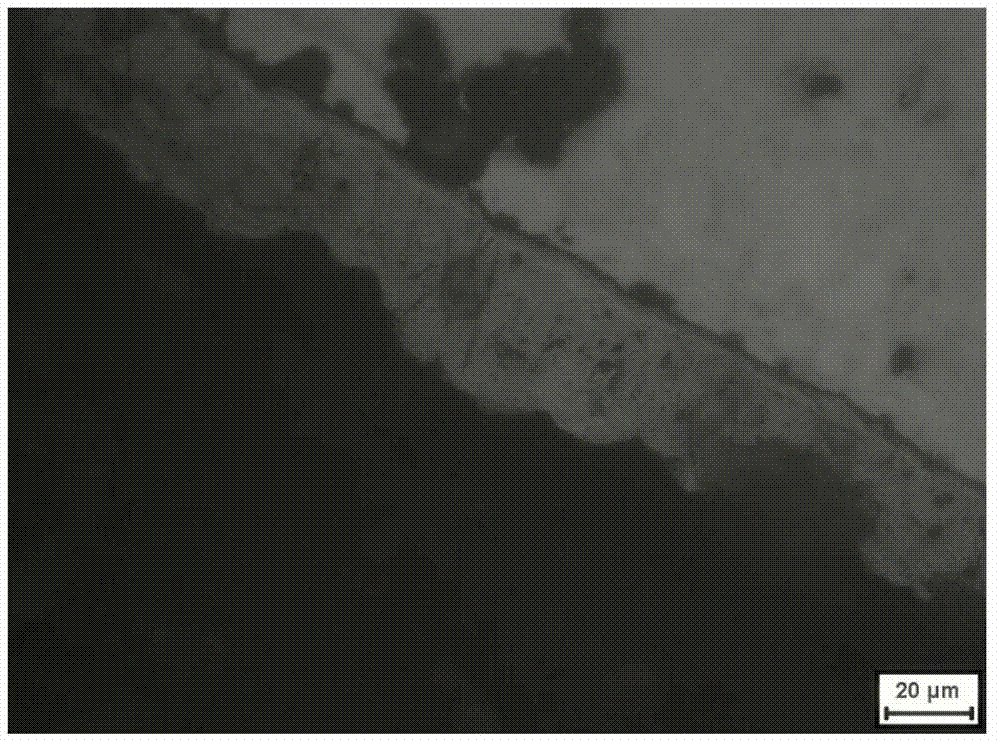

[0047] The copper coating on the surface of the magnesium-lithium alloy obtained in this embodiment is uniform and compact from a microscopic observation.

Embodiment 3

[0049] The copper plating solution formula is: copper pyrophosphate 50g / L; potassium pyrophosphate 300g / L; dipotassium hydrogen phosphate 40g / L; potassium sodium tartrate 40g / L; citric acid 0.1g / L; Lansu 0.02g / L. Electroplating conditions: electroplating temperature is 30°C; current density is 2A / dm 2 ; pH is 9; electroplating time 40min.

[0050] The specific steps of the copper electroplating process are the same as in Example 1. In this embodiment, the copper electroplating time is 40 minutes, the electroplating temperature is 30° C., and the current is adjusted to 0.04A.

[0051] The copper coating on the surface of the magnesium-lithium alloy obtained in this example is microscopically observed to be uniform and dense on the surface of the copper coating, and has no obvious defects.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com