Aerosol-generating article and method for manufacturing aerosol-generating articles

An aerosol generation and aerosol technology, which can be used in the manufacture of paper cigarettes, cigars, and applications, and can solve problems such as the impact of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

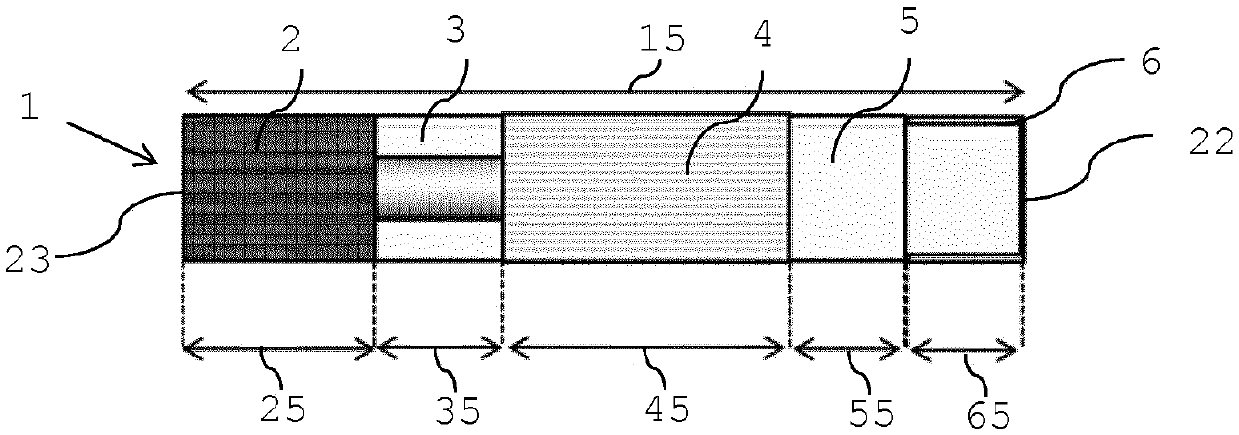

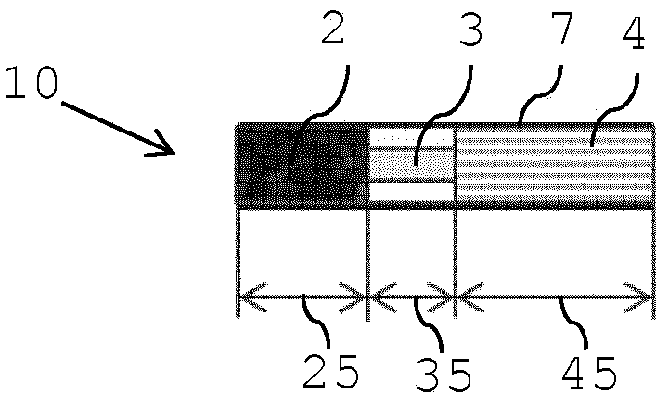

[0065] figure 1 (as well as Figure 4c , see below) illustrates an aerosol-generating article 1 comprising the following five elements: an aerosol-forming substrate 2, a support element in the form of a hollow cellulose acetate tube 3, an aerosol cooling element 4, a mouthpiece filter 5 and a cardboard tube 6 . These five elements are arranged sequentially and coaxially aligned, passing through the cigarette paper 7 and passing through the tipping paper 8 ( Figure 4c shown in ) are assembled to form strips. The strip has an oral end 22 which a user inserts into his or her mouth during use, and a distal end 23 at the opposite end of the strip opposite the oral end 22 . Elements located between the oral end 22 and the distal end 23 may be described as upstream of the oral end 22 , or alternatively as downstream of the distal end 23 . The cardboard tube 6 is located at the mouth end 22 of the aerosol-generating article 1 and the aerosol-forming substrate 2 is located at the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com