Rare earth modified brushing electroplating silver plating solution and preparing technology and use method of solution

A technology of electric brush plating and electric brush, which is applied in the field of electrochemistry, can solve the problems of plating solution stability, affect the concentration of silver ions, pollute the plating solution, etc., achieve uniform and compact appearance, avoid discoloration of the plating layer, and standardize the silver plating process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The invention provides a rare earth improved electric brush plating silver plating solution, comprising the following components and their mass concentrations: silver nitrate 15g / L, modifier rare earth cerium nitrate 1g / L, complexing agent sulfosalicylic acid 150g / L, Imidazole 100g / L, protective agent hexamethylenetetramine 0.5g / L, additive N,N-dimethylformamide 0.05g / L, polyethylene glycol 10g / L, ammonia water 20g / L, stabilizer ammonium acetate 30g / L, potassium pyrophosphate 15g / L, and adjust the pH value to 7.1 by dilute sodium hydroxide solution.

[0036] The invention provides a rare earth improved electric brush plating silver plating solution, the preparation process comprising the following steps:

[0037] (1) Prepare a mixed solution of improver, complexing agent, protective agent and stabilizer, and stir fully to make the dispersion uniform;

[0038] (2) Add N,N-dimethylformamide to the mixed solution in step (1) under stirring;

[0039] (3) under stirring, s...

Embodiment 2

[0051] The invention provides a rare earth improved electric brush plating silver plating solution, comprising the following components and their mass concentrations: silver nitrate 16g / L, modifier rare earth cerium nitrate 1.2g / L, complexing agent sulfosalicylic acid 140g / L , imidazole 110g / L, protective agent hexamethylenetetramine 0.6g / L, additive N,N-dimethylformamide 0.07g / L, polyethylene glycol 12g / L, ammonia water 18g / L, stabilizer acetic acid Ammonium 28g / L, potassium pyrophosphate 17g / L, and the pH value of the solution was adjusted to 6.9 by dilute nitric acid and dilute sodium hydroxide.

[0052] The preparation process and application method of this embodiment are the same as that of Embodiment 1.

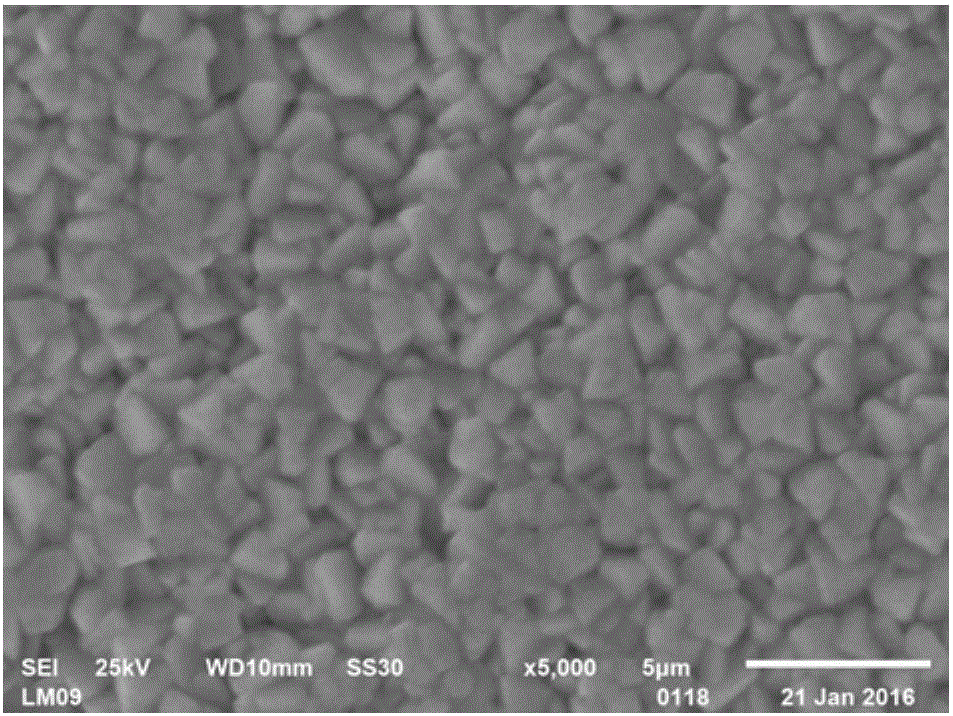

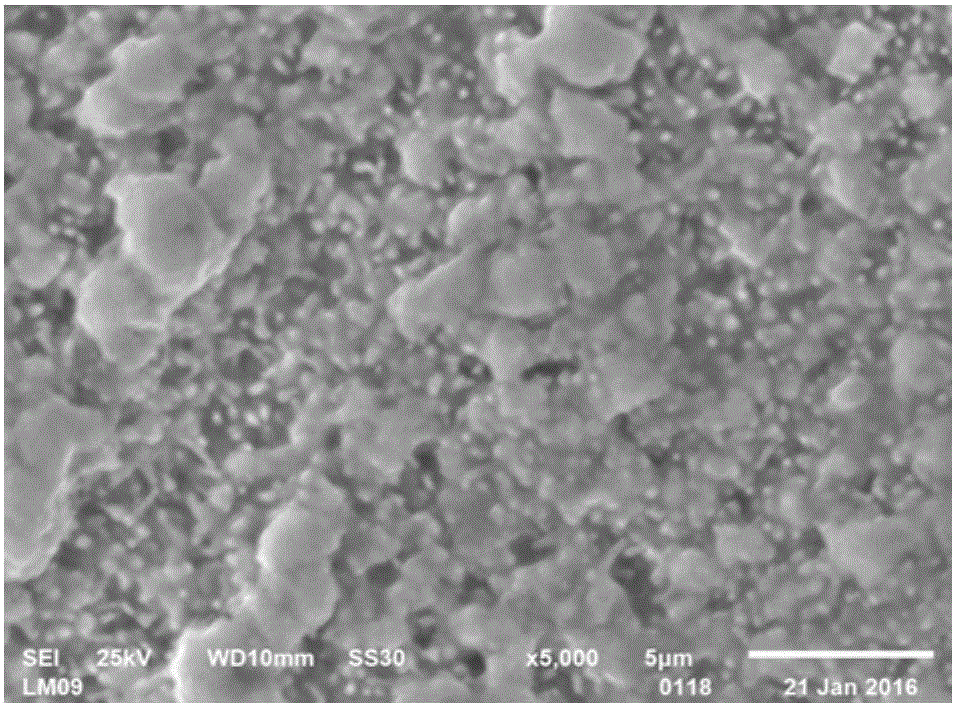

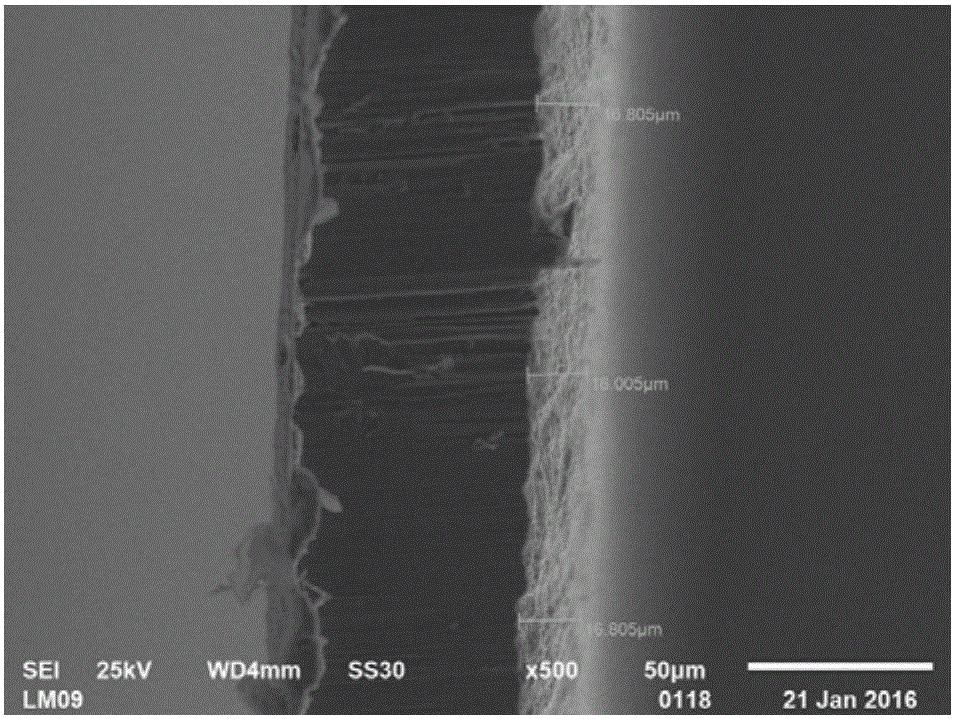

[0053] After a long time of sealing and standing (temperature 20-30°C), test the coating properties of the products of this embodiment at 0 months, 5 months, and 10 months of storage respectively after electroplating. The coating numbers are 1- number 3. The thickness...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com