Preparation method for titanium pyrophosphate with flower-like micron/nanometre structure

A nanostructure, titanium pyrophosphate technology, applied in the direction of nanotechnology, chemical instruments and methods, phosphorus compounds, etc., can solve problems that have not been reported, and achieve the effects of reducing production costs, protecting the environment, and simple processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Under the condition of 200r / min stirring, 0.68mmol phytic acid and 2mmol tetrabutyl titanate were added to 80mL absolute ethanol, after stirring evenly, the resulting mixture was transferred to a polytetrafluoro container with a volume of 95mL, and then polytetrafluoroethylene The PTFE container was placed in a stainless steel reaction kettle, and the kettle was sealed; the reaction kettle was kept at 180°C for static heat preservation for 12 hours to obtain a reaction solution. The obtained reaction solution was subjected to solid-liquid separation, and the liquid was recovered for use; the solid was washed with water and alcohol, and dried in an air atmosphere at 60°C for 10 hours to obtain the target product precursor.

[0028] The target product precursor obtained in the above steps was calcined at 680°C for 6 hours to prepare flower-like micro / nanostructured titanium pyrophosphate (sample S-1).

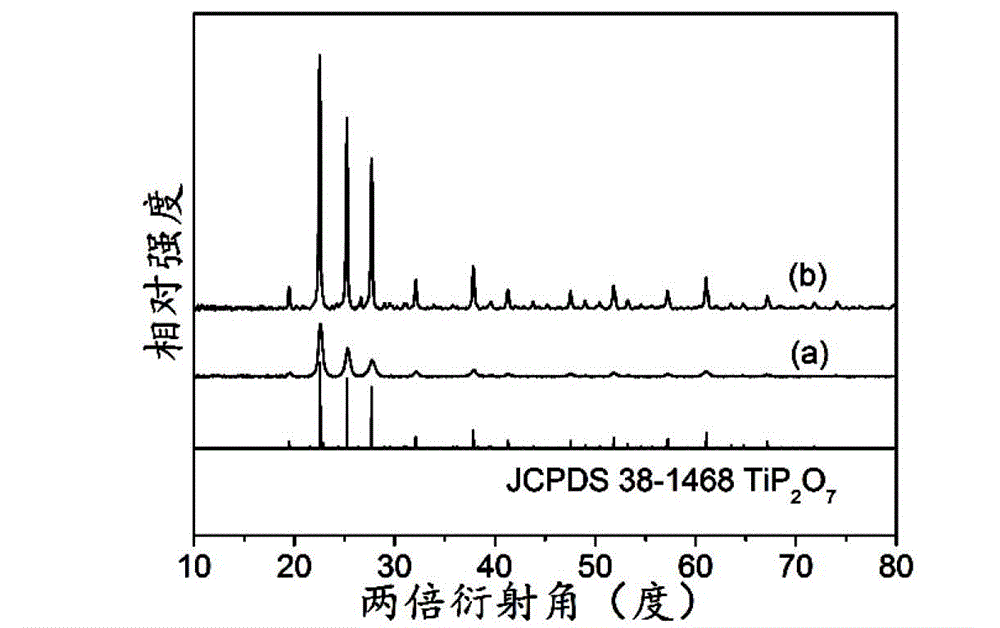

[0029] The XRD result of prepared sample S-1 ( figure 1 , curve (a))...

Embodiment 2

[0032] Under the stirring condition of 400r / min, 2.52mmol of phytic acid and 6mmol of isopropyl titanate were added to 30mL of absolute ethanol. The PTFE container was placed in a stainless steel reaction kettle, and the kettle was sealed; the reaction kettle was kept at 220°C for static heat preservation for 6 hours to obtain a reaction solution. The obtained reaction solution was subjected to solid-liquid separation, and the liquid was recovered for use; the solid was washed with water and alcohol, and dried in an air atmosphere at 120° C. for 6 hours to obtain the target product precursor.

[0033] The target product precursor obtained in the above steps was calcined at 800°C for 1 h to prepare flower-like micro / nanostructured titanium pyrophosphate (sample S-2).

[0034] The XRD result of prepared sample S-2 ( figure 1 , curve (b)) shows that sample S-2 is pure titanium pyrophosphate (JCPDS no.38-1468).

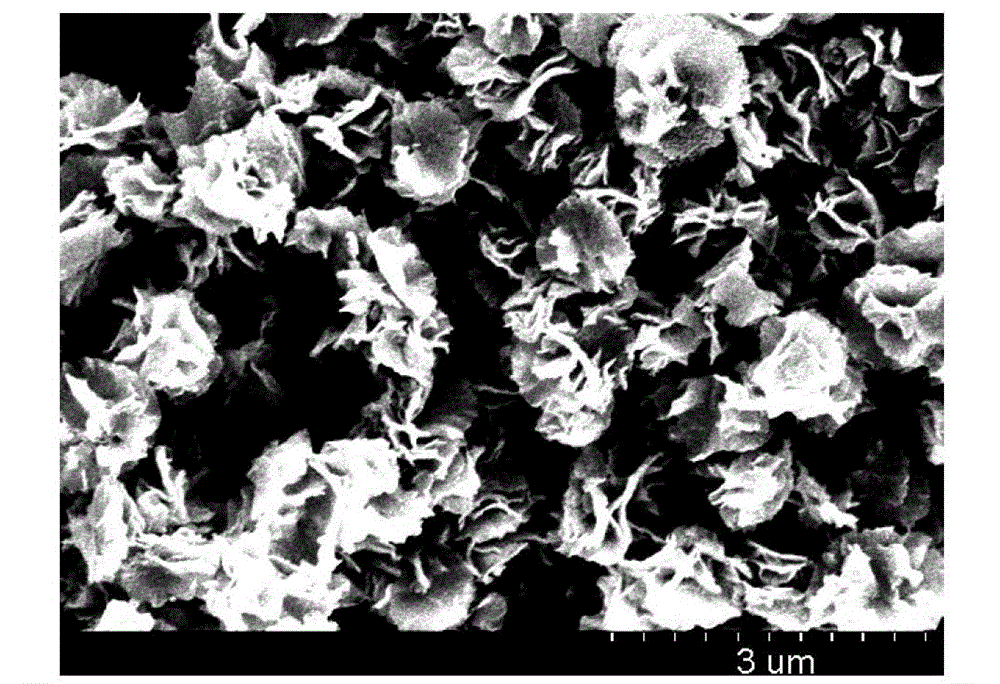

[0035] The scanning electron micrograph of prepared sample S-2 is ...

Embodiment 3

[0037] A preparation method of flower-like micro / nanostructure titanium pyrophosphate, comprising the steps of:

[0038] Under the condition of stirring at 300r / min, 1.4mmol phytic acid and 4mmol titanium tetrachloride were added to 70mL of absolute ethanol, after stirring evenly, the resulting mixture was transferred to a polytetrafluoro container with a volume of 95mL, and then the polytetrafluoroethylene The fluorine container was placed in a stainless steel reaction kettle, and the kettle was sealed; the reaction kettle was kept at 190°C for static heat preservation for 6 hours to obtain a reaction solution. The obtained reaction solution was subjected to solid-liquid separation, and the liquid was recovered for use; the solid was washed with water and alcohol, and dried in an air atmosphere at 70°C for 10 hours to obtain the target product precursor.

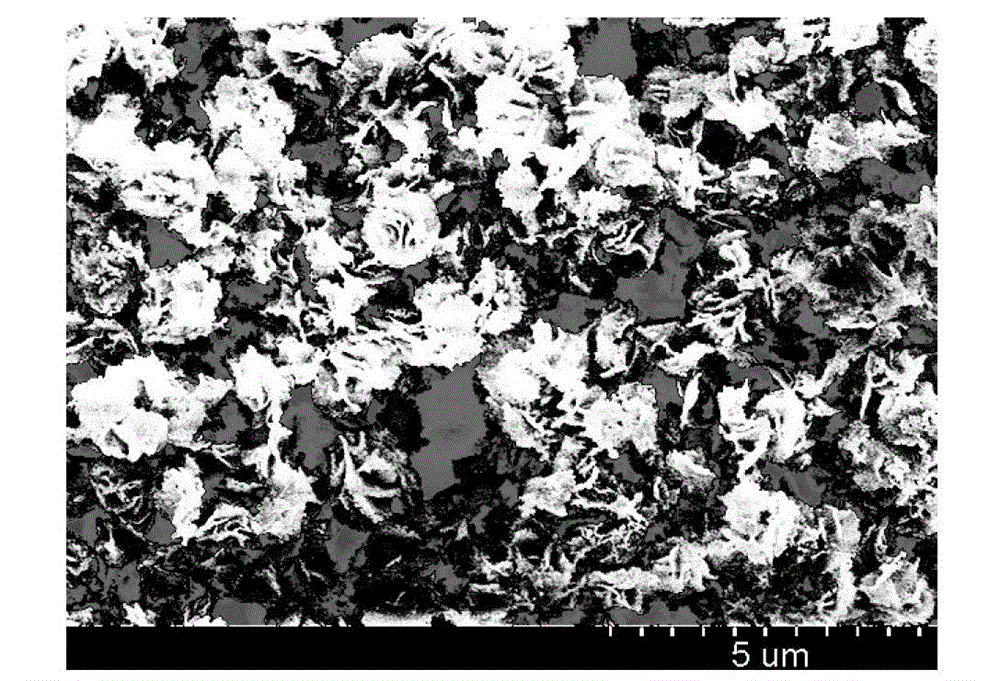

[0039]The target product precursor obtained in the above steps was calcined at 750° C. for 2 hours to prepare flower-like...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com