Method for electroplating shaft bushing antifriction layer by metilsulfate plating bath

A methanesulfonate and electroplating shaft technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of difficult emission standards, low yield, and environmental hazards, and achieve uniform coating thickness and fine coating crystallization , The effect of simple electroplating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

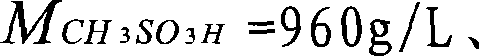

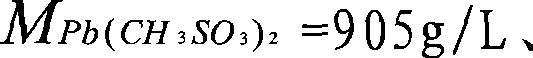

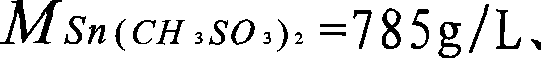

Embodiment 1

[0012] Double-sided electroplating of lead-tin-copper alloy plating on a platinum sheet with a specification of 3×4cm after degreasing and weighing. Activate with dilute hydrochloric acid prepared from 1 volume of concentrated hydrochloric acid to 3 volumes of water for 1 to 2 minutes, wash the activated platinum sheet with water, and then use the above-mentioned methanesulfonate plating solution at room temperature. The anode is a lead-tin alloy containing 10% tin. , cathode current density 2.5A / dm 2 , double-sided electroplating for 20 minutes on the platinum sheet to obtain a uniform, smooth and dense lead-tin-copper coating on the surface. The thickness of the prepared lead-tin-copper coating on the platinum sheet was measured to be 22 μm, and the content of the lead-tin-copper coating was dissolved by acid and analyzed by volume: 7.8% tin, 2.3% copper, and 89.9% lead.

Embodiment 2

[0014] Electroplate lead-tin-copper plating on the inner surface of 15 copper-lead alloy bearing bushes with specifications of 490QZL at the same time. The bearing bush first uses NaOH containing 12g / L, containing Na 2 CO 3 25g / L, containing Na 3 PO 4 12H 2 O is 60g / L, containing Na 2 SiO 3 It is a 12g / L degreasing liquid, and ultrasonic degreasing is carried out at a temperature of 50°C for 5 minutes; after the ultrasonic degreasing of bearing bushes, the NaOH content of 12g / L and Na 2 CO 3 25g / L, containing Na 3 PO 4 12H 2 O is 35g / L, containing Na 2 SiO 3 It is 7g / L electrolytic degreasing fluid, use steel plate as anode at room temperature, and the cathode current density is 2.5A / dm 2 Conduct electrolytic degreasing for 4 minutes; after the second degreasing and cleaning of the bearing bush, activate it with dilute hydrochloric acid with a volume ratio of 1:3, that is, dilute hydrochloric acid composed of 1 volume of concentrated hydrochloric acid and 3 volumes...

Embodiment 3

[0017] Electroplate lead-tin-copper coatings on the inner surfaces of 45 copper-lead alloy bearing bushes whose specifications are 490QZL at the same time. The bearing bush first uses NaOH containing 12g / L, containing Na 2 CO 3 25g / L, containing Na 3 PO 4 12H 2 O is 60g / L, containing Na 2 SiO 3 It is a 12g / L degreasing liquid, and ultrasonic degreasing is carried out at a temperature of 60°C for 5 minutes; after the bearing bush is ultrasonically degreased, the NaOH containing 12g / L and NaOH are used for hanging. 2 CO 3 25g / L, containing Na 3 PO 4 12H 2 O is 35g / L, containing Na 2 SiO 3 It is 7g / L electrolytic degreasing fluid, use steel plate as anode at room temperature, and the cathode current density is 2.5A / dm 2 Carry out cathodic electrolytic degreasing for 5 minutes; after the second degreasing and cleaning of the bearing bush, activate it with dilute hydrochloric acid with a volume ratio of 1:3 for 2 minutes; put the activated bearing bush into 60 liters of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com