Method for installing rail steel backing plate by transplanting technique

A technology for steel backing plates and tracks, which is applied to tracks, track laying, and track maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

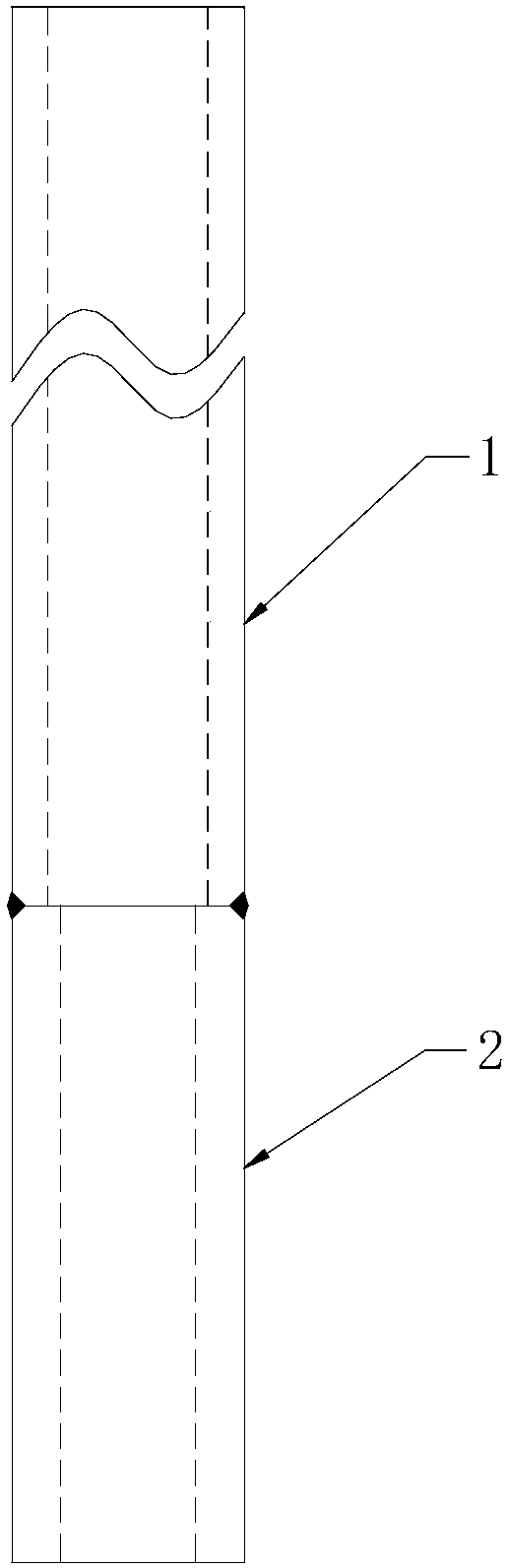

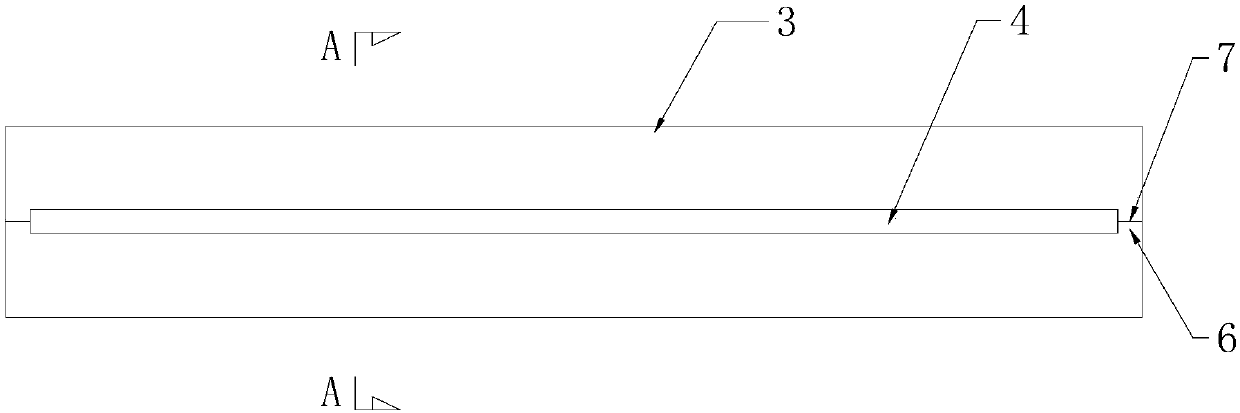

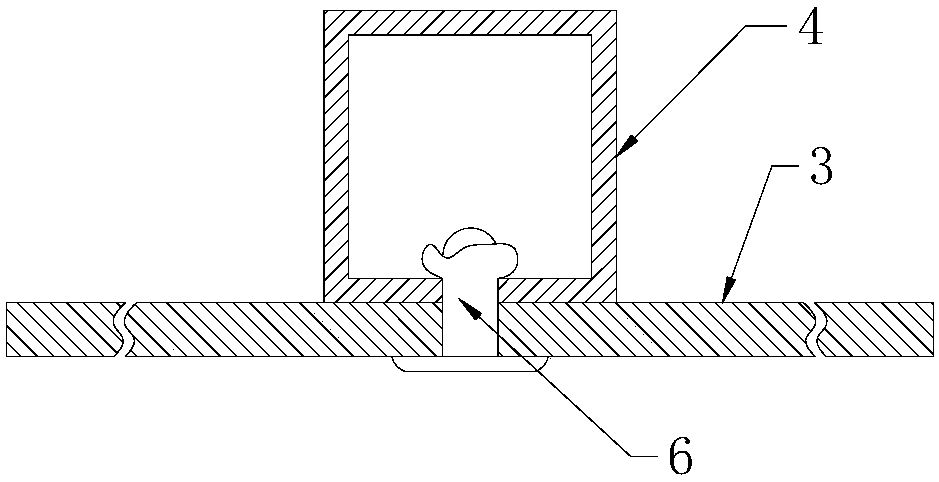

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0028] The method for installing the track steel backing plate using the value-shifting technology includes the following specific steps:

[0029] a. Clean the track groove, and straighten the embedded bolts through the straightening device, so that the inclination between the embedded bolts and the horizontal plane is not more than 1 degree, and prepare for the subsequent installation of the steel backing plate;

[0030] b. Erection of the center line of the track groove;

[0031] c. Use a 3-4mm thick transparent hard plastic plate to make the grafting plate, preferably a 3mm thick transparent hard plastic plate. The length of the transplanting plate is consistent with the length of a single track steel backing plate, and the width is the same as the width of the track steel backing plate consistent;

[0032] d. Lay the transplant plate on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com