Spring seat mounts for shock absorbers

A technology of fixing devices and spring seats, applied in the direction of shock absorbers, springs, spring/shock absorber design features, etc., can solve problems such as failure to meet safety requirements, loss of car control, traffic accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

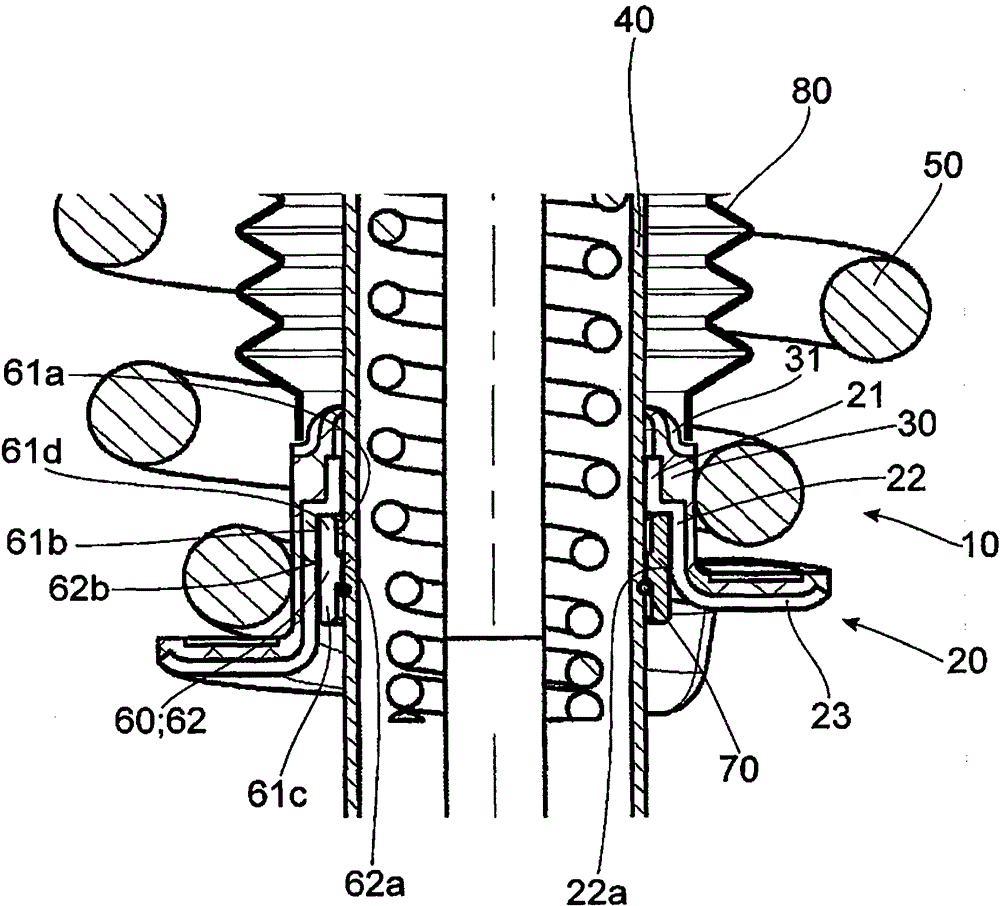

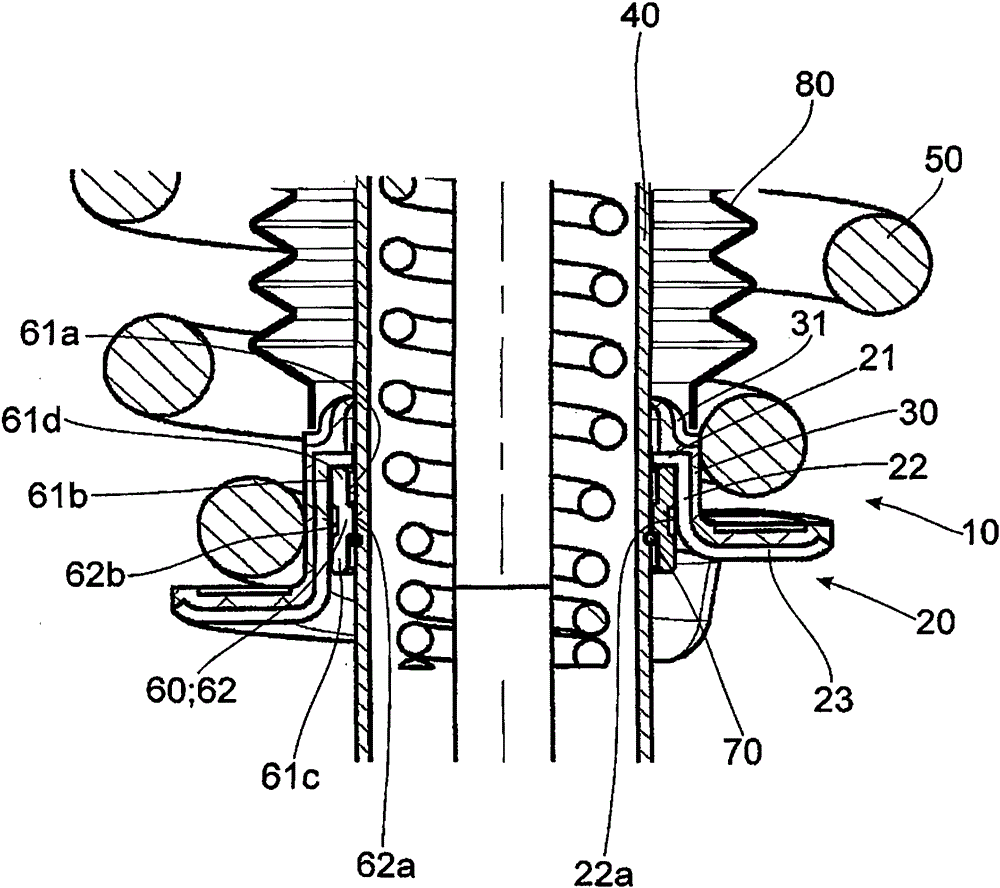

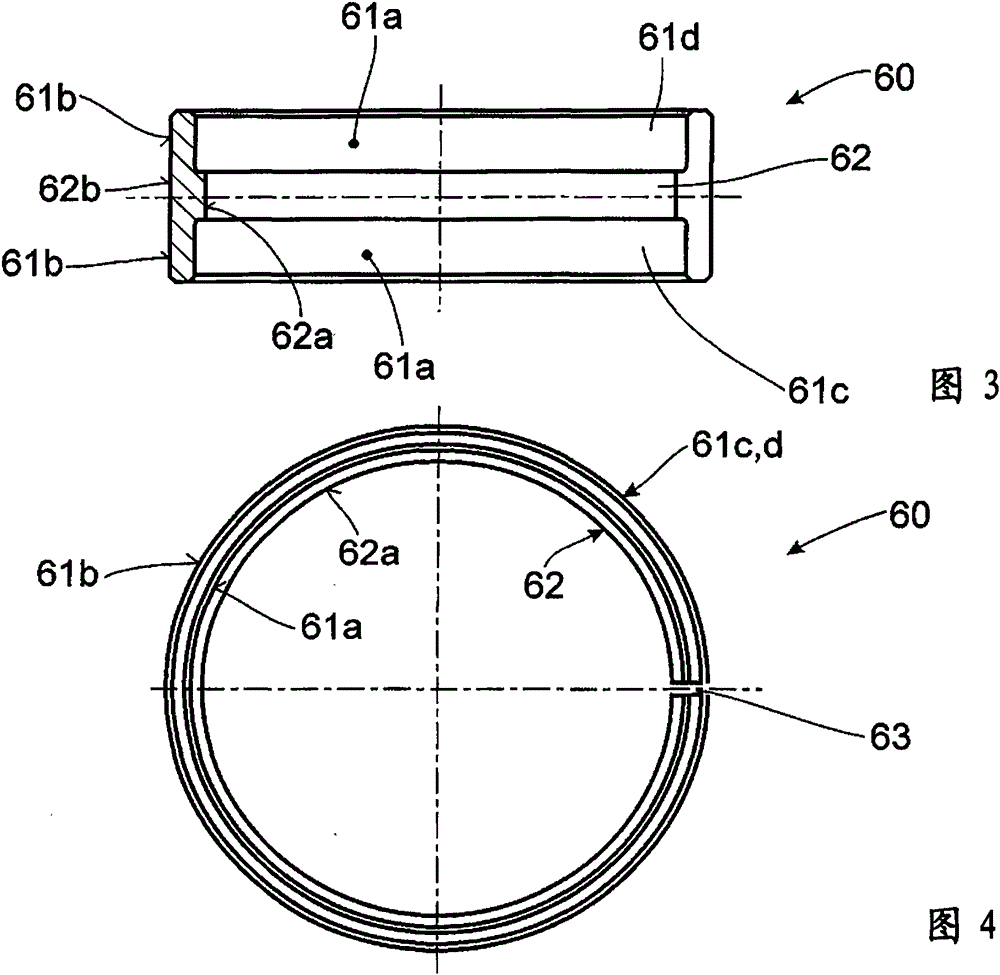

[0027] figure 1 A spring seat fixing device 10 for a shock absorber according to the present invention is shown. The spring seat fixing device includes a spring seat 20 having a contact section 21 that surrounds the vibration damping tube 40 in the circumferential direction. In addition, the spring seat 20 further has a receiving section 22 spaced from the contact section 21 in the axial direction and in the radial direction, and a support section 23 spaced from the contact section 21 in the axial direction. The support section 23 here supports the suspension spring 50 in the axial direction via its substantially disk-shaped radial extension. In addition, in figure 1 as well as figure 2 Shown therein is an isolation element 60 implemented as a one-piece, which also encloses the damping tube 40 and is arranged inside the receiving section 22 of the spring seat 20. figure 2 with Figure 5 The insulation element 60 shown is embodied as a thin sheet metal molded part.

[0028] in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com