Method for producing a vehicle traction battery

A technology for power batteries and vehicles, applied in battery/battery traction, batteries, manufacturing tools, etc., which can solve problems such as incorrect placement of battery modules and damage to battery module performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

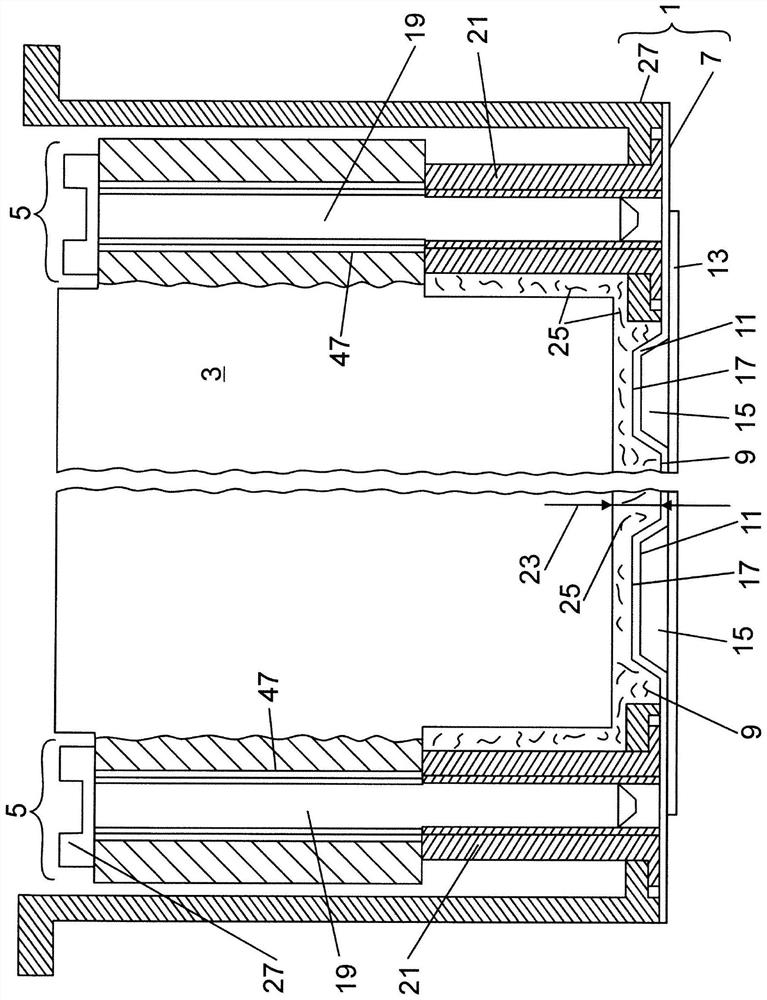

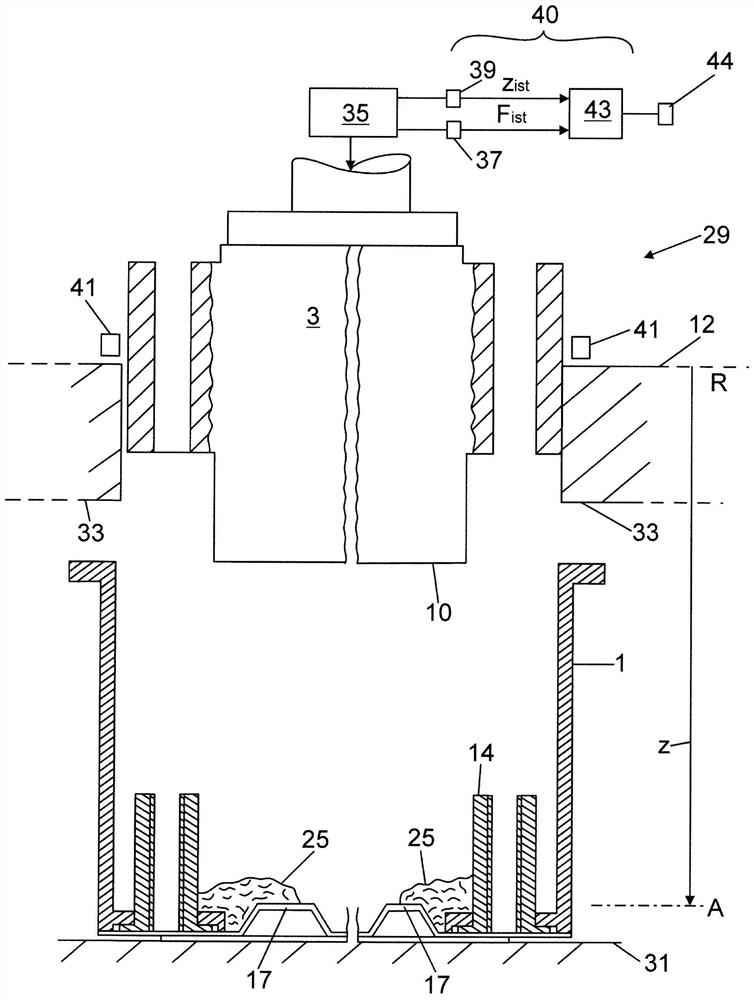

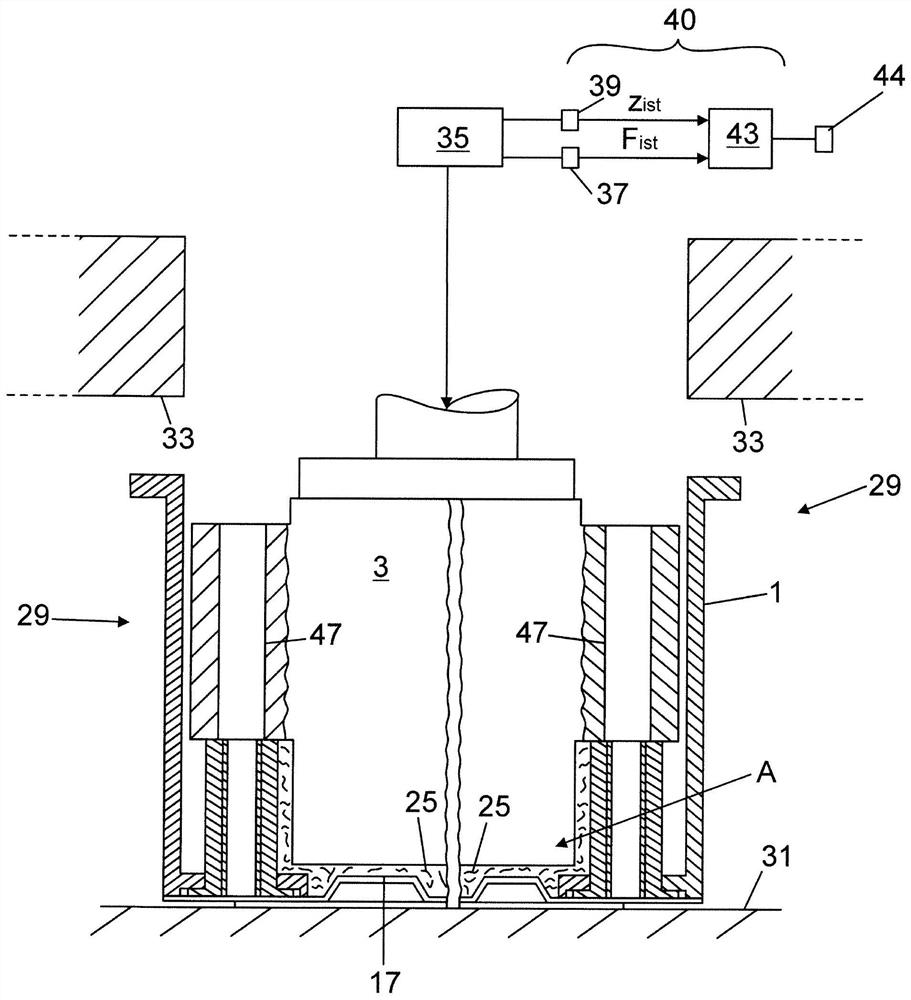

[0018] exist figure 1 , the traction battery of an electric vehicle is shown in a roughly simplified side sectional view. The traction battery has a pot-shaped or box-shaped battery housing 1 , in which a rectangular battery module 3 is accommodated, which consists of individual cells (not shown). The battery module 3 is mounted on the housing bottom 7 of the battery housing 1 by means of a fastening unit 5 . Such as figure 1 It is further shown that the housing bottom 7 has a housing bottom base 9 and a cooling embossment 11 which is raised from the housing bottom base by a pressing height in the direction of the housing interior. The cooling emboss 11 together with the lower cover part 13 delimits a coolant channel 15 which is a component of the external vehicle cooling system. The upper side of the cooling pressing part 11 is in figure 1 A contact contour 17 is formed in , on which the battery module 3 is placed via an insulating layer of thermally conductive paste.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com