Fixing structure used for self-moving nut

A technology for fixing structures and nuts, applied in the directions of transportation, packaging, vehicle parts, etc., can solve the problems of wasting time and personnel, increasing the difficulty of installation, and increasing costs, saving installation time, reducing the number of personnel, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

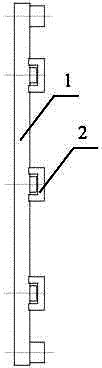

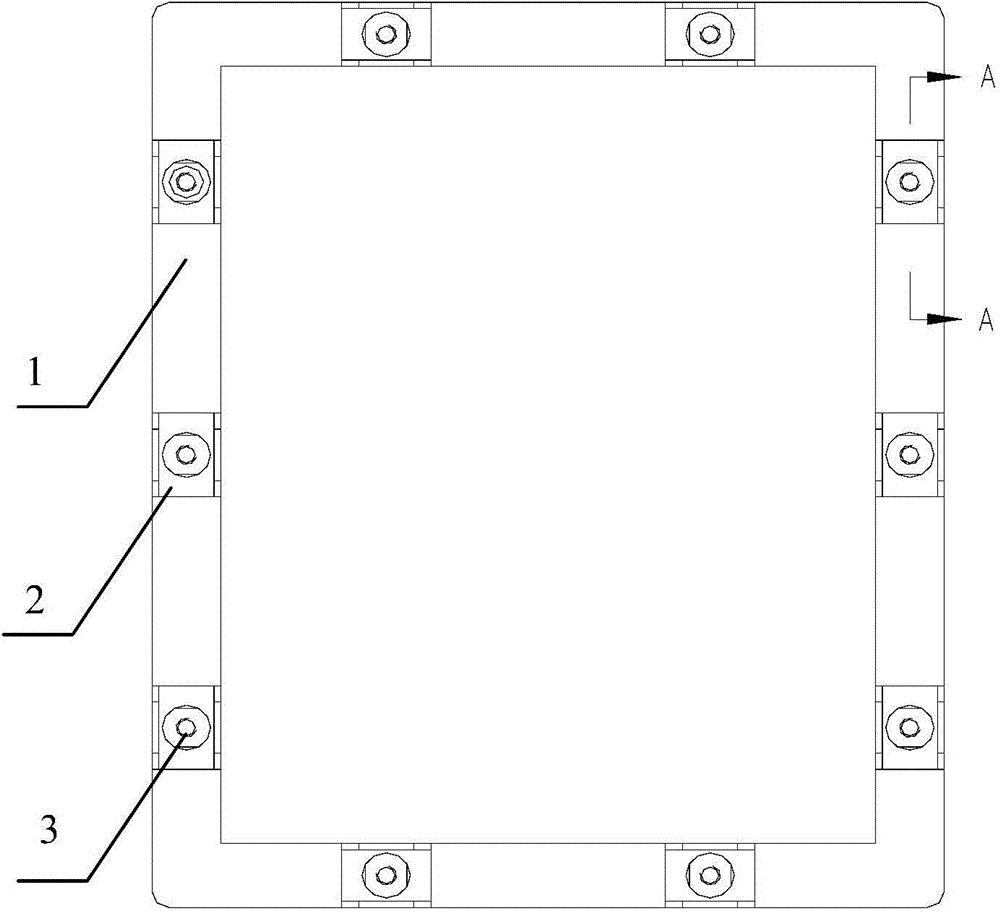

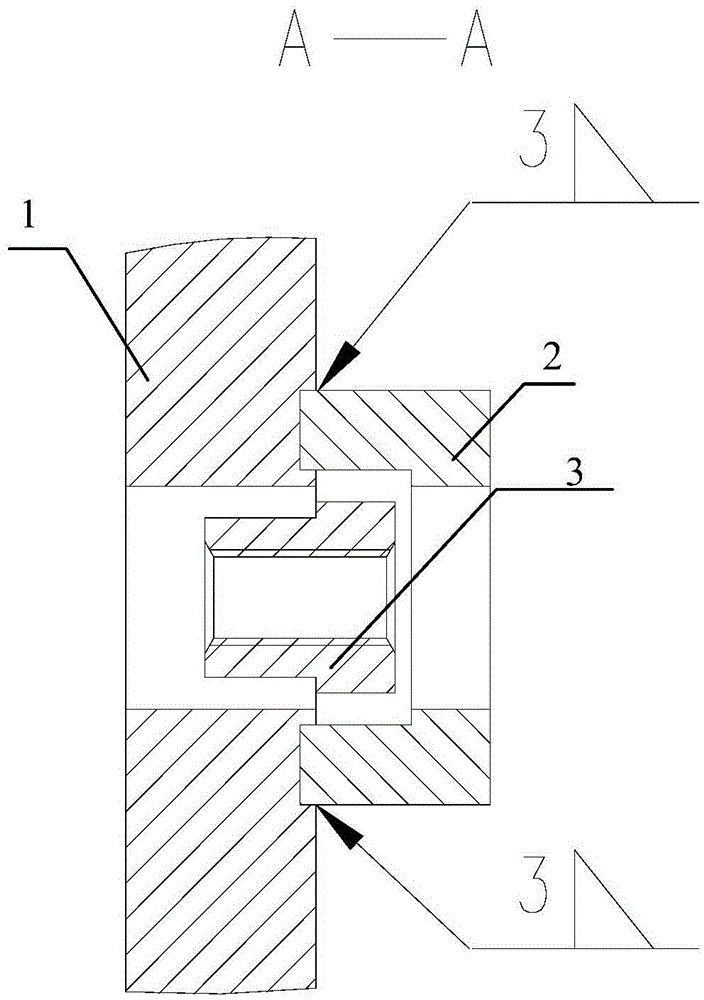

[0036] figure 1 Shows the front view of the self-moving nut fixing structure of the embodiment of the present invention, figure 2 is based on figure 1 side view of the structure. from figure 1 with figure 2 It can be seen from the figure that the self-movable nut fixing structure includes installation equipment, a limit kit 2, a movable nut 3 and a carrier plate 1.

[0037] First, determine the number of mounting holes on the car body according to the weight and size of the target equipment.

[0038] In the case that the number of vehicle body mounting holes determined according to the weight and size of the target equipment is small, and the manufacturing precision is high, there will be basically no problem that multiple mounting holes cannot be installed. At this time, this The fixing structure of the embodiment of the invention only needs to install the equipment, the limit kit 2 and the movable nut 3 .

[0039] in, figure 1 and figure 2 The car body between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com