Impregnation forming method for capacitor core assembly

A technology of impregnation molding and capacitors, which is applied in capacitors, capacitor manufacturing, circuits, etc., can solve problems such as high viscosity of liquids, difficult penetration of core groups, aging failures, etc., and achieve the reduction of liquid surface tension, stable feeding speed, and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

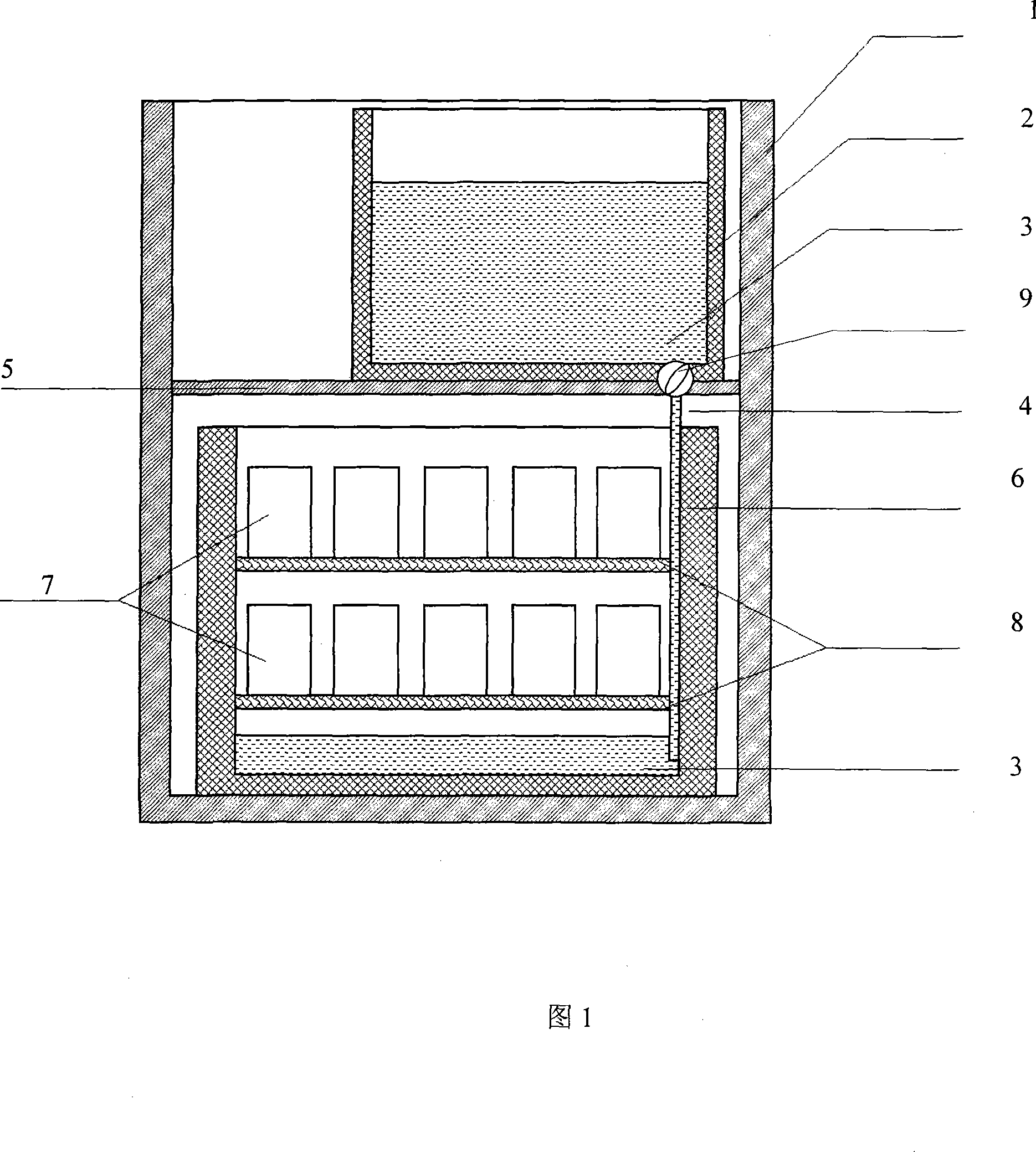

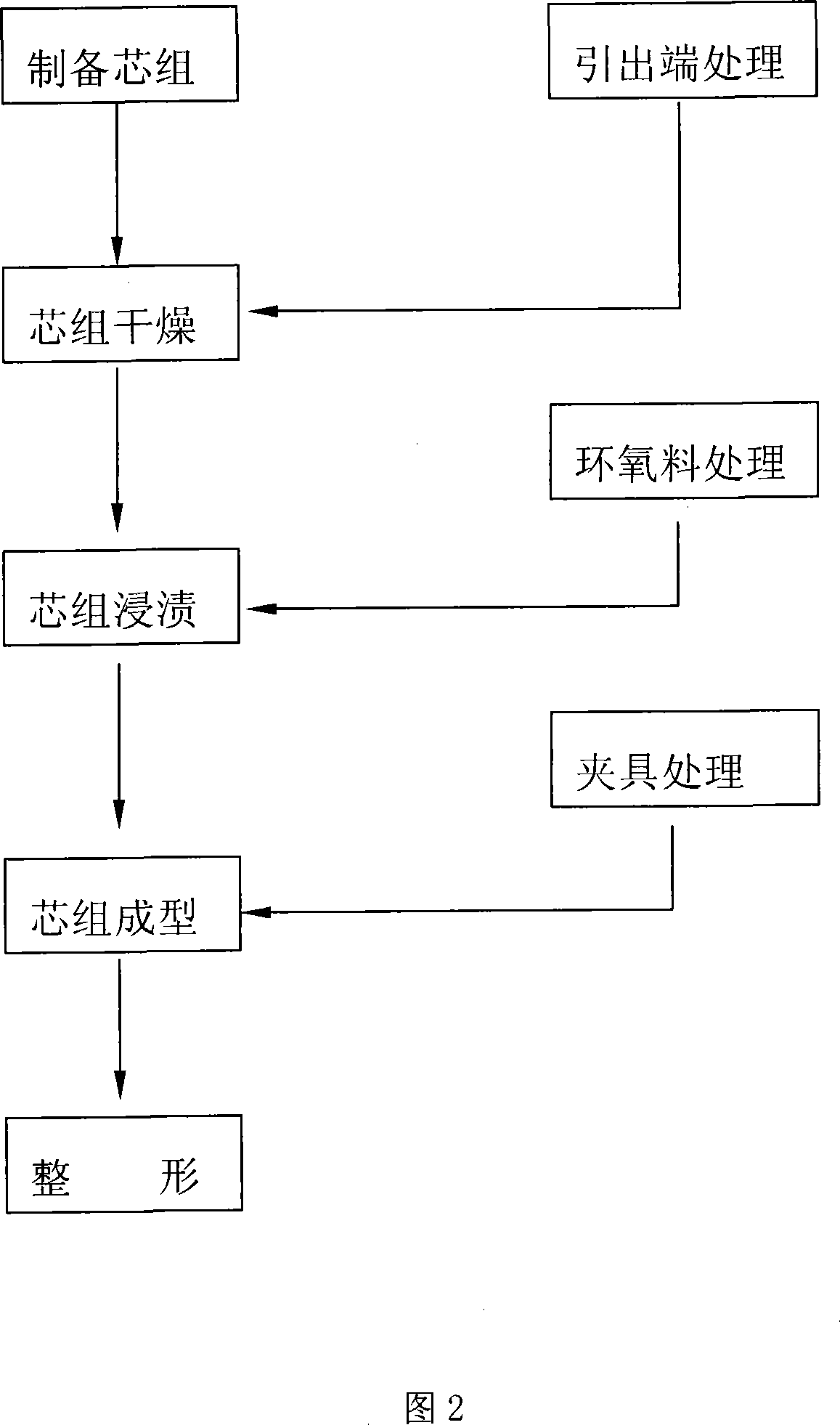

[0026] As shown in Figure 1, the specific implementation is divided into the following steps:

[0027] 1) Prepare the capacitor core group first,

[0028] 2) Prepare the impregnation device and fixture, including impregnation material, porous isolation wire mesh (8), limit washer, and forming press plate for use; the impregnation device includes a material container (1) and a vacuum container (6), and the material container (1) communicates with the vacuum container (6) through the guide rod (4), and the material container (1) is also provided with a discharge valve (9); one end of the guide rod (4) is connected to the vacuum chamber with the core The bottom or inner wall of the container (6) is connected, and the other end is connected with the discharge valve (9);

[0029] 3) Coat the lead part of the core group with an isolating agent to isolate the epoxy resin from the fixture, core, and core metal lead-out parts, reducing the difficulty of subsequent operations. The isol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com