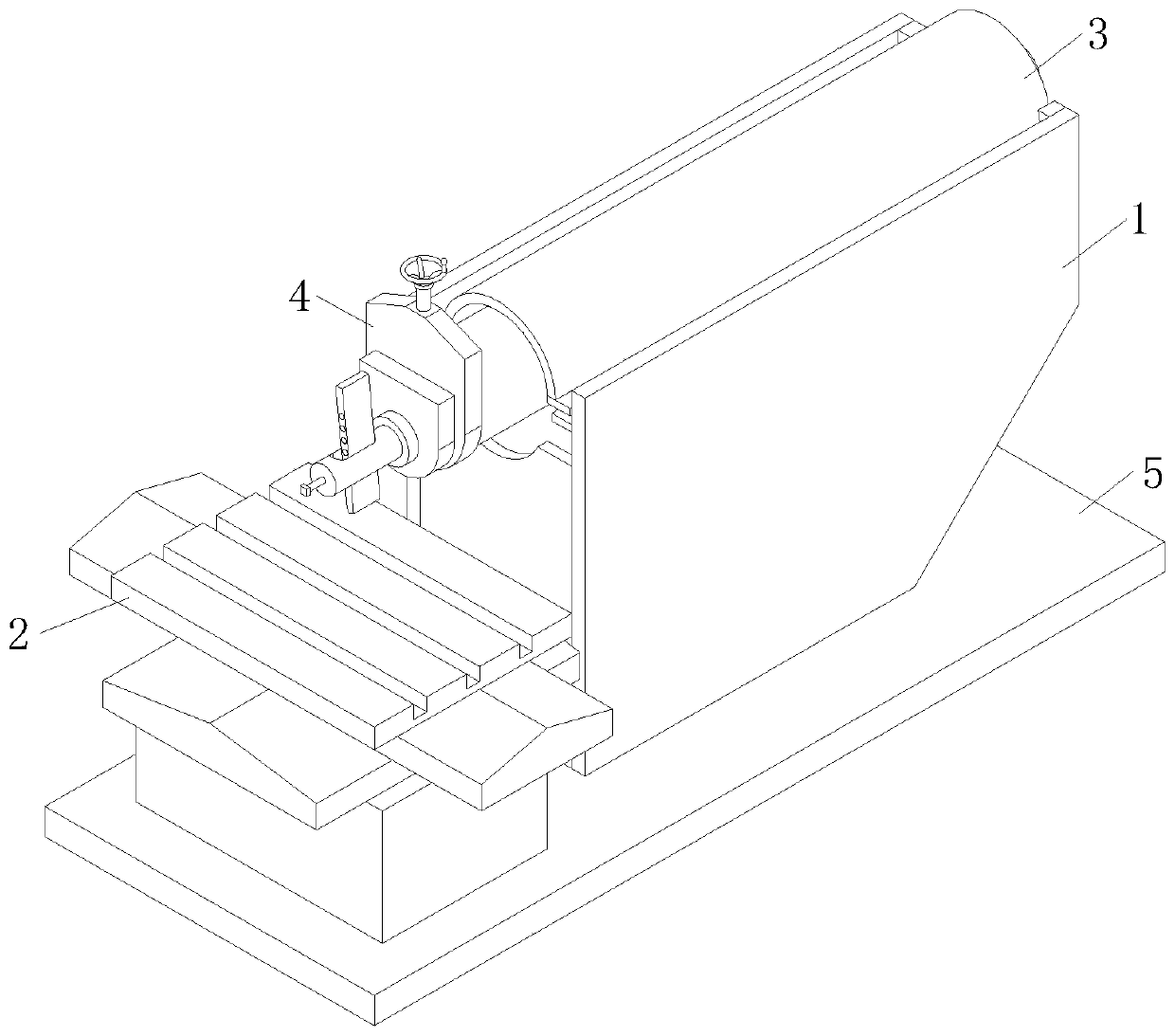

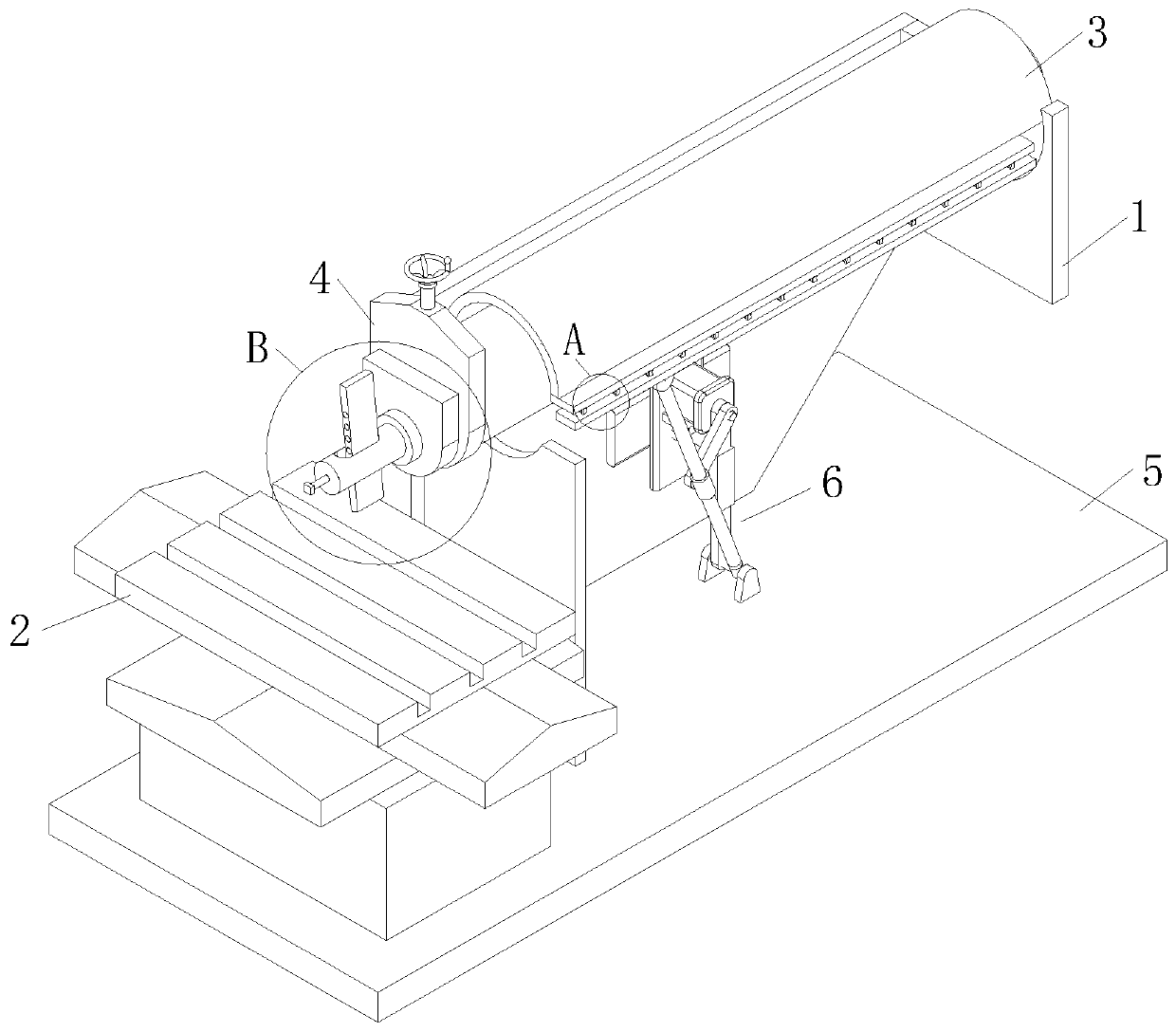

Shaping machine

A planer and bed technology, which is applied in the direction of planer/slotting machine, slotting machine, metal processing equipment, etc., can solve the difficulty of stabilizing the processing effect of the planer, unsolved problems of speed stability of the planer, and the processing quality effect of the planer In order to avoid the influence of static friction, improve the processing effect and improve the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

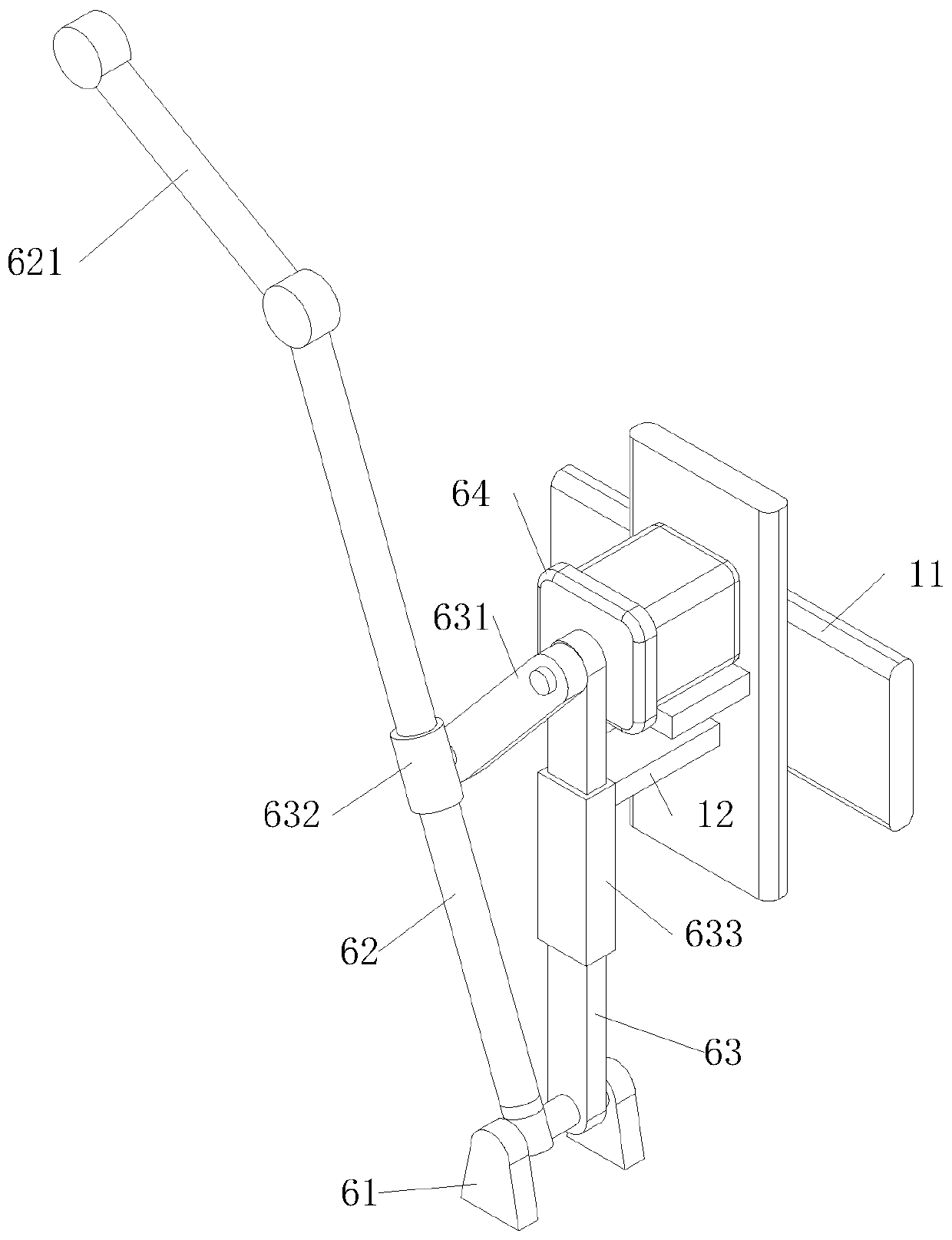

[0028] As an embodiment of the present invention, the upper part of the bed 1 is provided with a slide rail 13, and the slide rail 13 is provided with roller bearings 131, and the roller bearings 131 are evenly distributed on the slide rail 13, and the roller bearings The ram 3 is slidingly installed on the 131; when working, the ram 3 is directly slidably installed on the upper part of the bed 1, and the relatively smooth plane between the bottom of the ram 3 and the bed 1 is used as a sliding contact surface, and the ram 3 reciprocates During the movement, it is necessary to repeatedly overcome the static friction force to achieve the effect of the reciprocating movement of the ram 3, which causes additional loss to the output power of the linkage mechanism 6; through the roller bearing 131 arranged on the slide rail 13 of the bed 1, When the slide rail 13 reciprocates on the bed 1, the rolling contact with the roller bearing 131 avoids the influence of static friction betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com