A rotary quantitative feeding device and its measuring method

A technology of quantitative feeding device and measuring method, which is used in measuring devices, rotary conveyors, weighing, etc., can solve the problems of increasing the difference of material quantity, the deviation of material centroid, the deviation of material centroid, and the uniform distribution of materials. , to achieve the effect of ensuring the instantaneous feeding rate, improving the measurement accuracy and stabilizing the feeding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

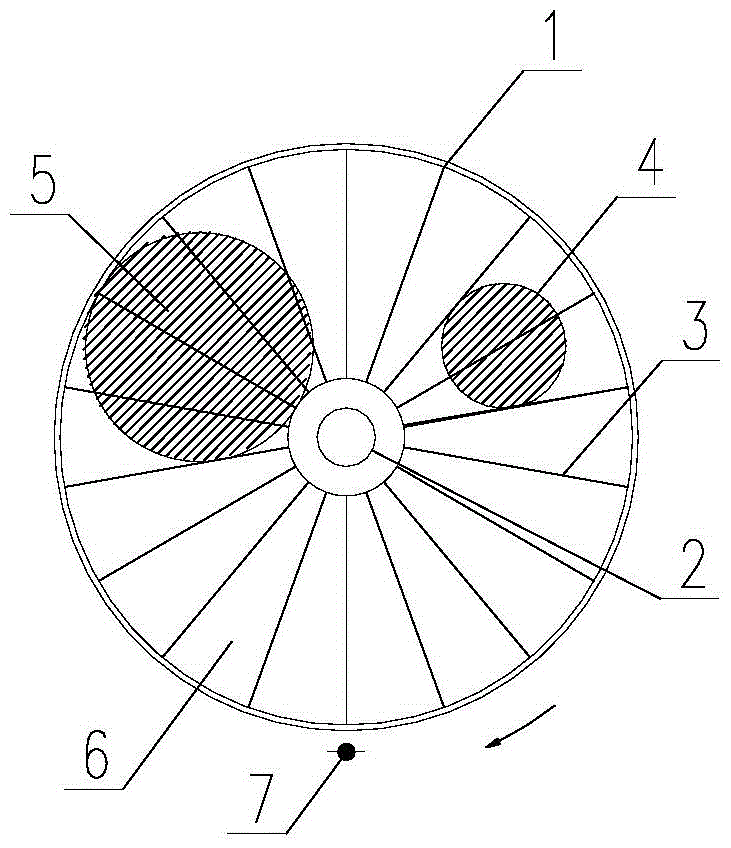

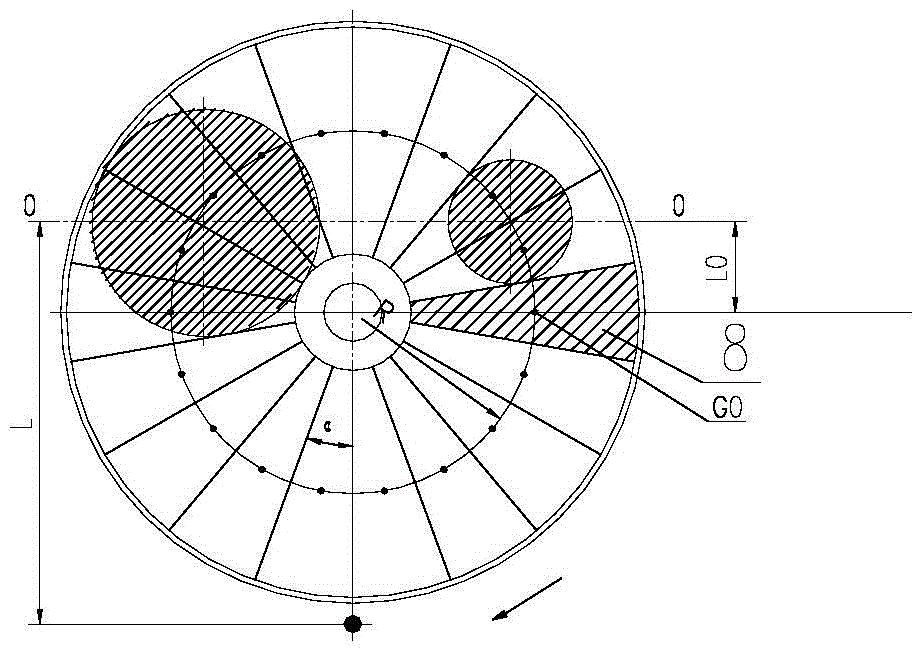

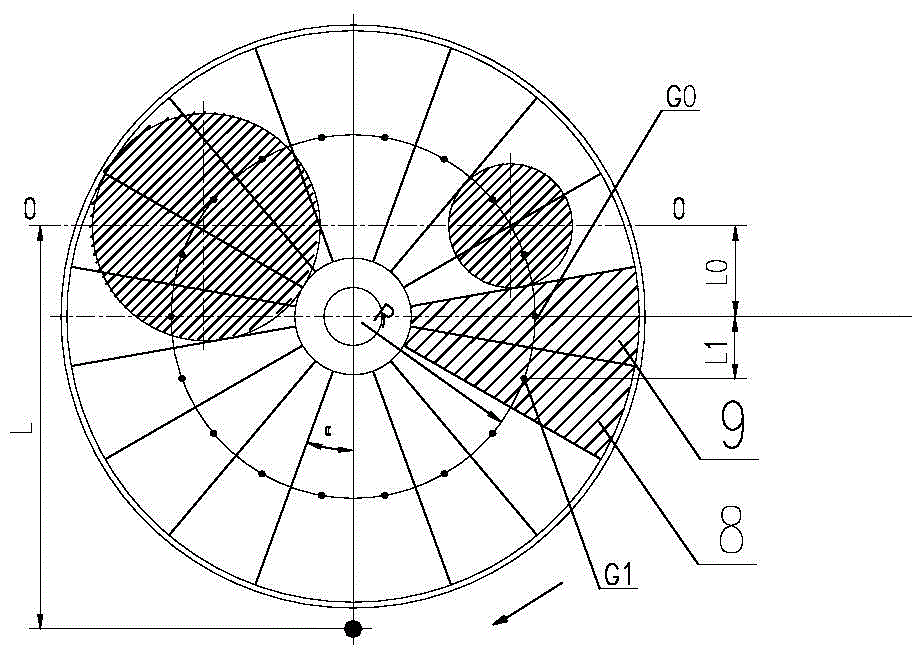

[0034] like Figure 1-4 As shown, this embodiment provides a rotary quantitative feeding device, including a housing 1, a rotatable rotary wheel 2 disposed in the housing 1, and a material inlet 4 and a material outlet 5 arranged on the housing 1 , The rotary wheel 2 is provided with a number of uniformly arranged blades 3, wherein a fan-shaped space 6 for holding materials is formed between two adjacent blades 3.

[0035] The rotary dosing device also includes a weighing device 7, preferably, the weighing device 7 is a load cell. The fulcrum connection line of the feeding device is located on one side of the equipment center, the weighing device 7 is located on the other side of the equipment center, and the weighing device 7 is located on the center line of the fulcrum connection line.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com