Numerically-controlled double-end saw

A cutting saw and saw blade technology, which is applied in the field of CNC double-head sawing, can solve the problems that the feeding speed of the cutting saw blade is not stable enough, affecting the use function of the double-head cutting saw, etc., and achieves stable feeding speed, convenient operation, extended The effect of the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

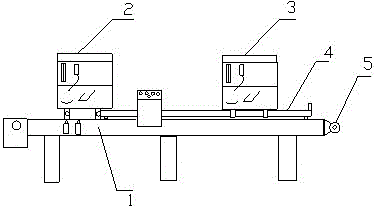

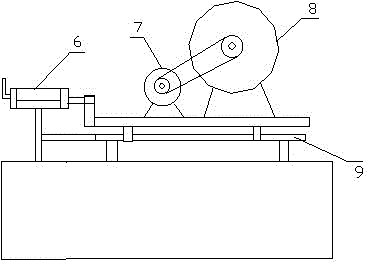

[0010] see figure 1 As shown in -2, a numerically controlled double-head cutting saw includes a body 1, a fixed sawing mechanism 2, a movable sawing mechanism 3, and drives the movable sawing mechanism along a horizontal straight line 3 provided on the body 1. The servo motor 5 that moves the guide rail 4, the fixed sawing mechanism 1 is respectively provided with a longitudinal linear guide rail 9, a cutting saw blade 8, a spindle motor 7 that drives the rotation of the cutting saw blade 8, and drives the fixed sawing mechanism 1 A feed mechanism 6 that moves along the longitudinal linear guide rail 9, and the feed mechanism 6 is a gas-hydraulic damping cylinder.

[0011] Because the present invention adopts the gas-liquid damping cylinder with the advantages of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com