Numerical controller

A technology of numerical control device and control unit, applied in the direction of program control, computer control, general control system, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

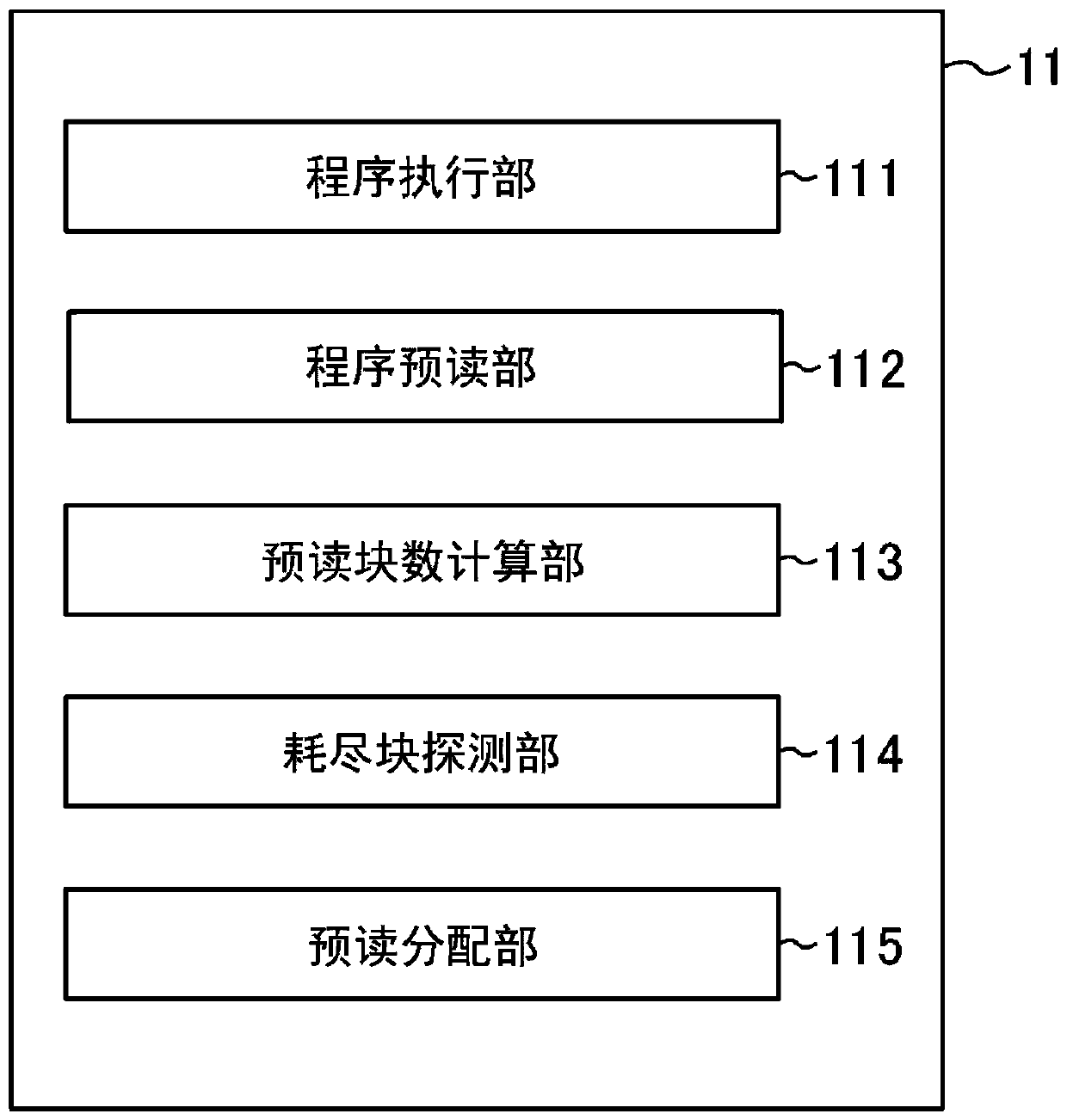

[0041] [1.1 Structure of the invention]

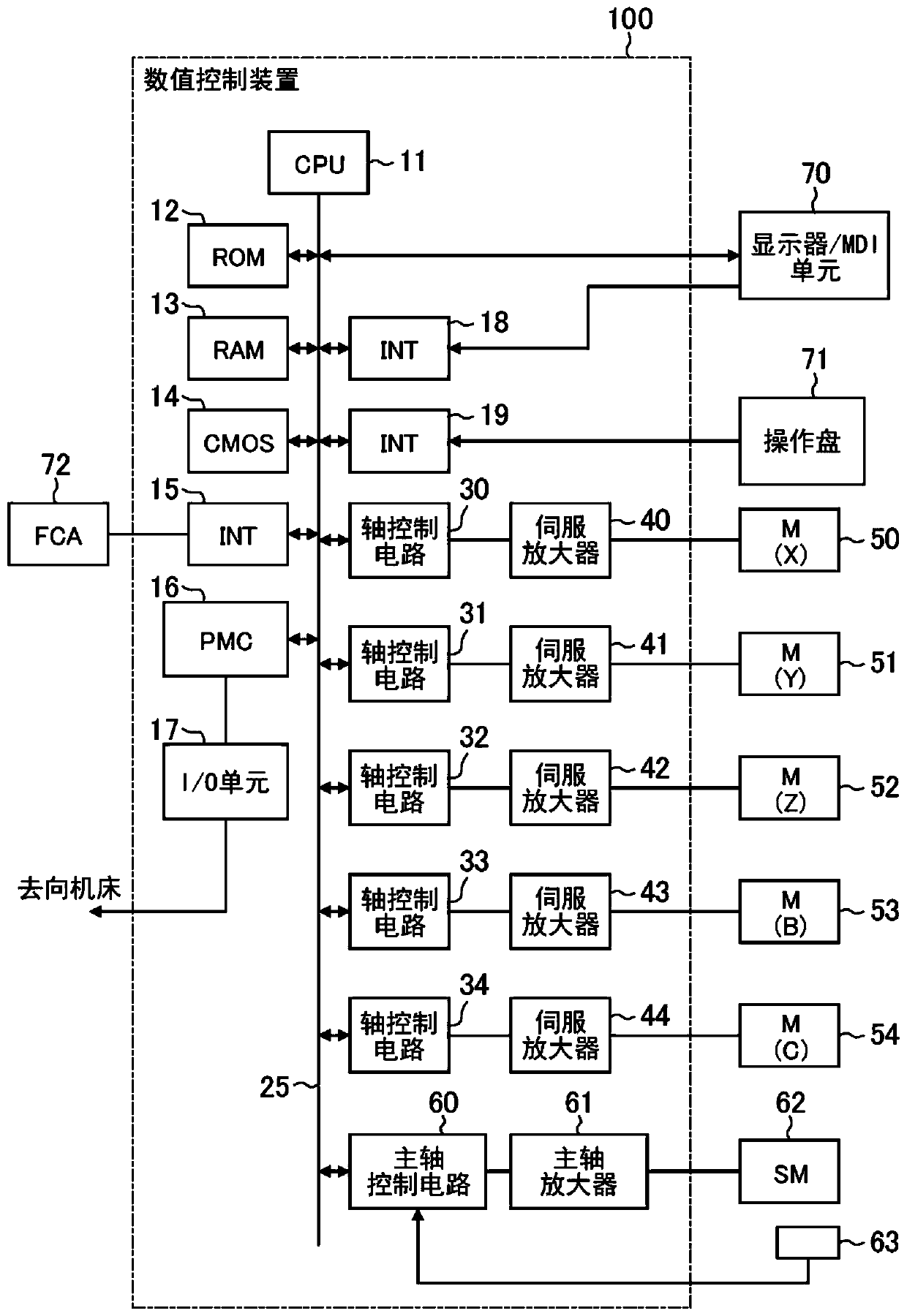

[0042] figure 1 A configuration of a control system 10 including a numerical controller 100 according to the first embodiment of the present invention and a machine tool 200 controlled by the numerical controller 100 is shown.

[0043] The numerical control device 100 is a device that outputs operation commands to the machine tool 200 and performs numerical control on the machine tool 200 by having functions described later. Details of the configuration and functions of the numerical controller 100 will be described later.

[0044] The machine tool 200 is an apparatus for performing predetermined machining such as cutting. The machine tool 200 includes a motor driven to machine a workpiece, a main shaft attached to the motor, a feed shaft, jigs, tools, and the like corresponding to these respective shafts. Further, the machine tool 200 performs predetermined machining by driving a motor based on an operation command output from the...

no. 2 approach 〕

[0101] Below, by referring to Figure 9 and Figure 10 A second embodiment of the present invention will be described. In addition, in order to simplify the description, the numerical control device 100A according to the second embodiment will be mainly described below in terms of differences from the numerical control device 100 according to the first embodiment.

[0102] [2.1 Structure of the invention]

[0103] A numerical controller 100A according to the second embodiment is different from the numerical controller 100 according to the first embodiment in that it includes a CPU 11A instead of the CPU 11 .

[0104] Figure 9 is a functional block diagram of the CPU 11A. Unlike the CPU 11 , the CPU 11A does not include the look-ahead block number calculation unit 113 and the exhausted block detection unit 114 , but instead includes a machining accuracy index calculation unit 116 and a machining accuracy required block detection unit 117 .

[0105] The machining accuracy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com