Automatic magnetic steel drilling machine

A technology of magnetic steel and countersunk hole, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing, etc., can solve the problems of low processing efficiency, high labor intensity, inclined drilling, etc., to improve processing efficiency , Improve the processing quality, the effect of stable feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

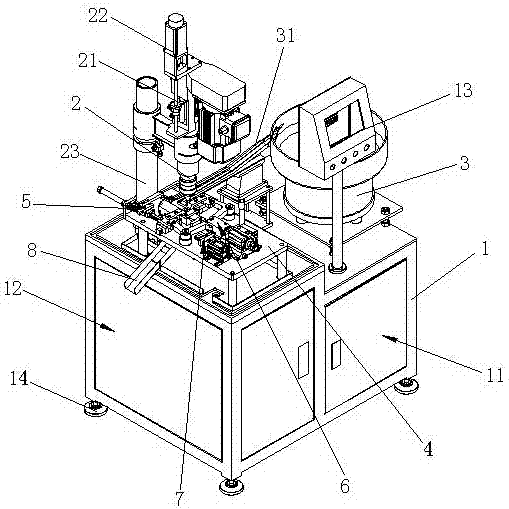

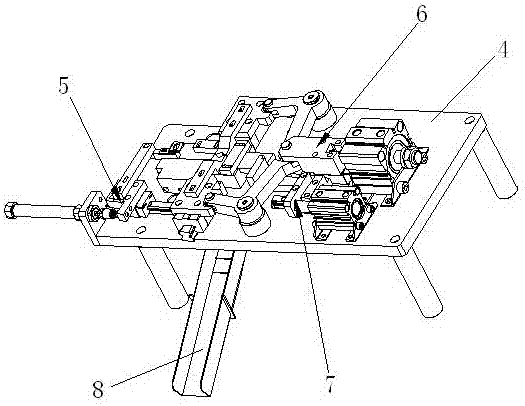

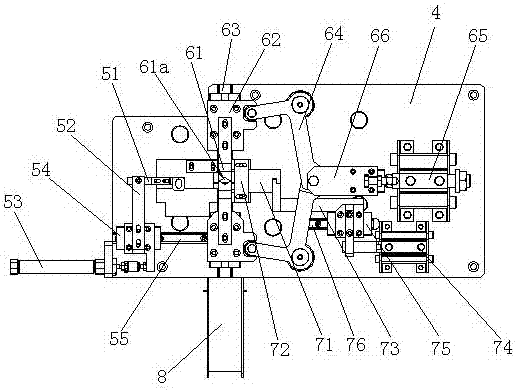

[0022] Such as Figure 1 to Figure 3 Shown is the structural representation of the present invention,

[0023] The reference signs are: frame 1, power distribution cabinet 11, water tank cabinet 12, console 13, support feet 14, drilling rig 2, ball screw 21, servo motor 22, column 23, vibration plate 3, direct vibration Slideway 31, bracket 4, feeding mechanism 5, feeding push block 51, feeding connecting rod 52, feeding cylinder 53, feeding slider 54, feeding slide rail 55, workpiece clamping mechanism 6, clamping block 61 , V-shaped groove 61a, clamping slider 62, clamping slide rail 63, connecting rod 64, clamping cylinder 65, connecting block 66, blanking mechanism 7, slide plate 71, baffle plate 72, blanking connecting rod 73, Blanking cylinder 74, blanking slide block 75, blanking slide rail 76, blanking slideway 8.

[0024] Such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com