Efficient plate shearing machine

A shearing machine, high-efficiency technology, applied in the direction of shearing device, shearing machine equipment, shearing machine accessories, etc., can solve the problems of low efficiency, achieve high flexibility, wide application range, and improve stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

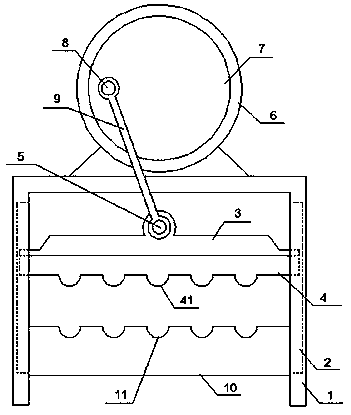

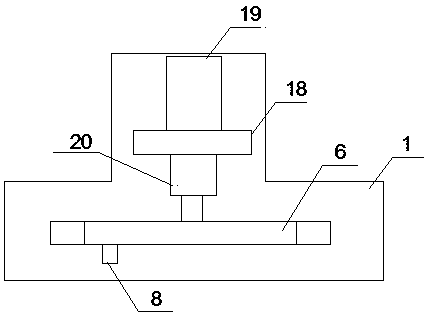

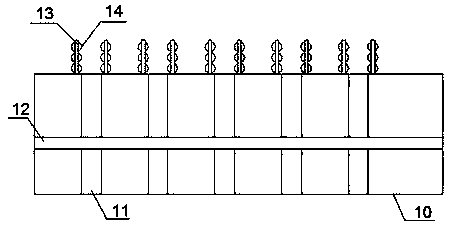

[0021] Such as Figure 1-4 As shown, the present invention discloses a high-efficiency plate shearing machine, comprising a frame 1 and a binder plate 34, the frame 1 is an inverted U shape, and the inner walls of the left and right sides of the frame 1 are respectively provided with chute 2. A tool holder 3 is slidably connected in the chute 2; a blade 4 is fixedly connected to the lower end of the knife holder 3, and a plurality of blades 41 are uniformly arranged on the lower end of the blade 4; the middle of the upper end of the tool holder 3 is fixedly connected There is a rotating shaft one 5; the upper end of the frame 1 is fixedly connected with a turret 6, and the rotating frame 6 is connected with a rotating disk 7; the front plane of the rotating disk 7 is fixedly connected with a rotating shaft 2 8, and the rotating shaft 2 8 is located at the position where the turntable 7 is far away from the center of the circle, the first rotating shaft 5 is rotationally connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com