Biomass gasification equipment

A technology for gasification equipment and biomass, which is applied in the manufacture of combustible gas, petroleum industry, etc., can solve the problems of weak feeding capacity of gasifier, high cost of use, low purity of gasification gas, etc., and achieves good continuous working performance, Long service life and good gasification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

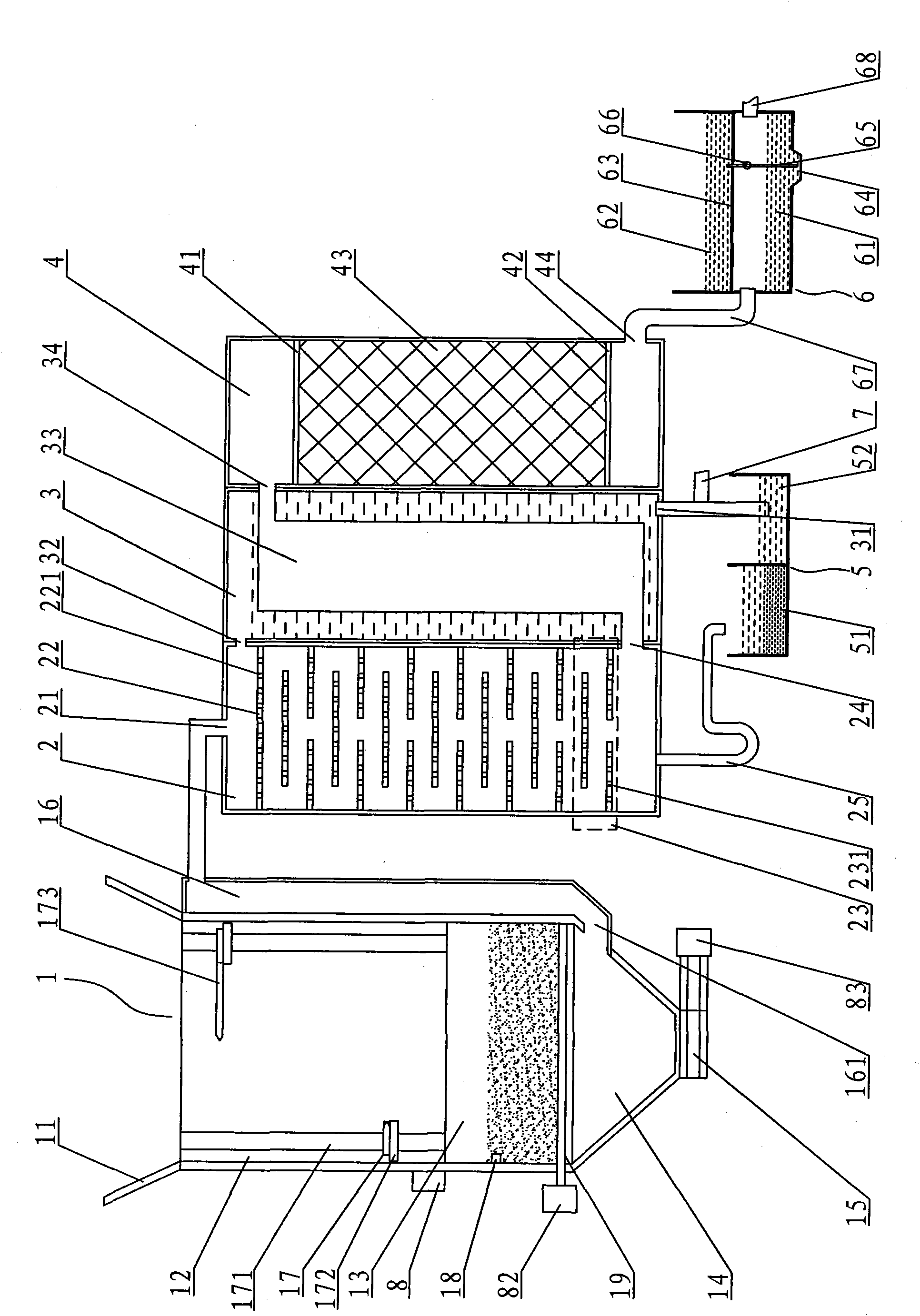

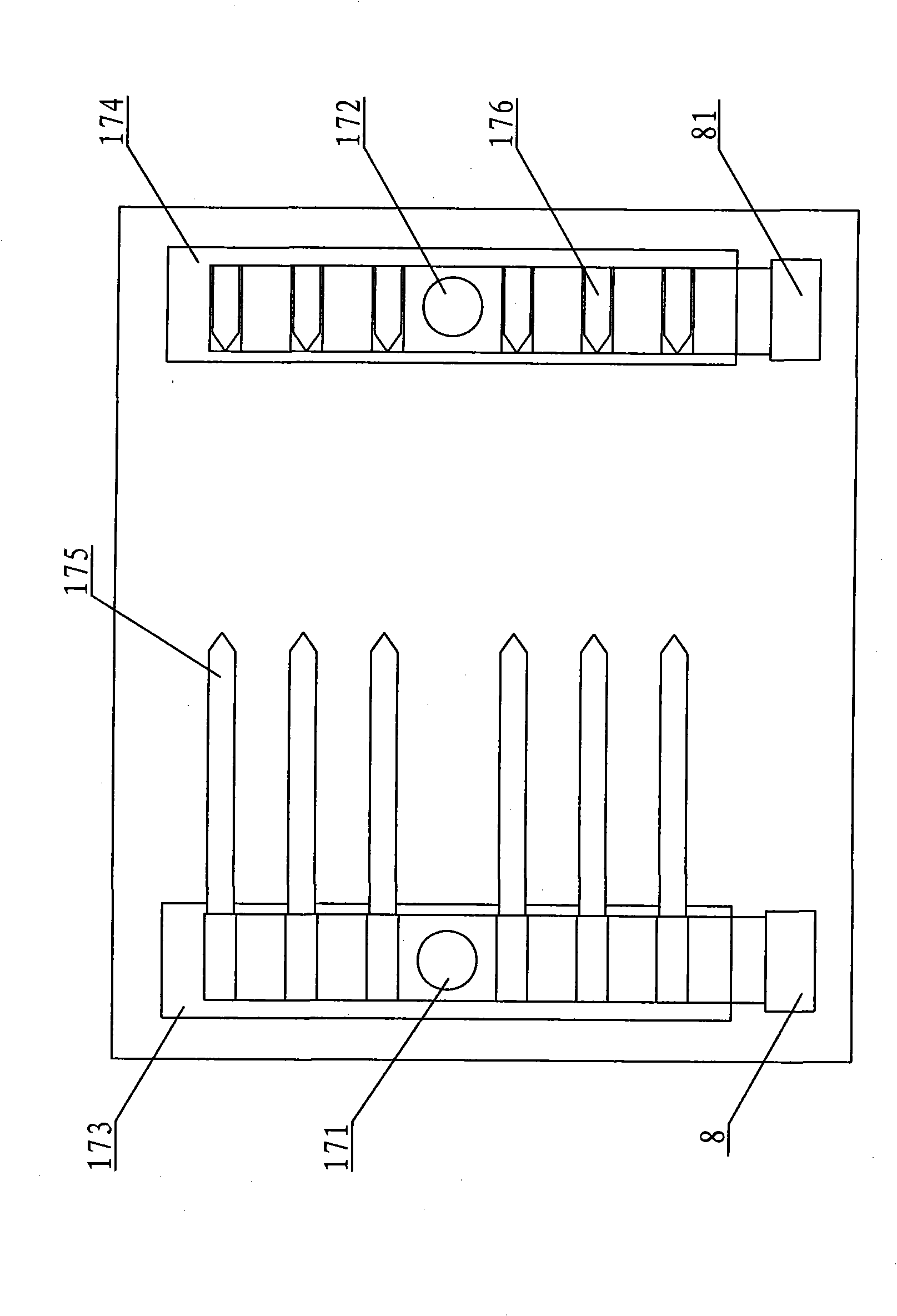

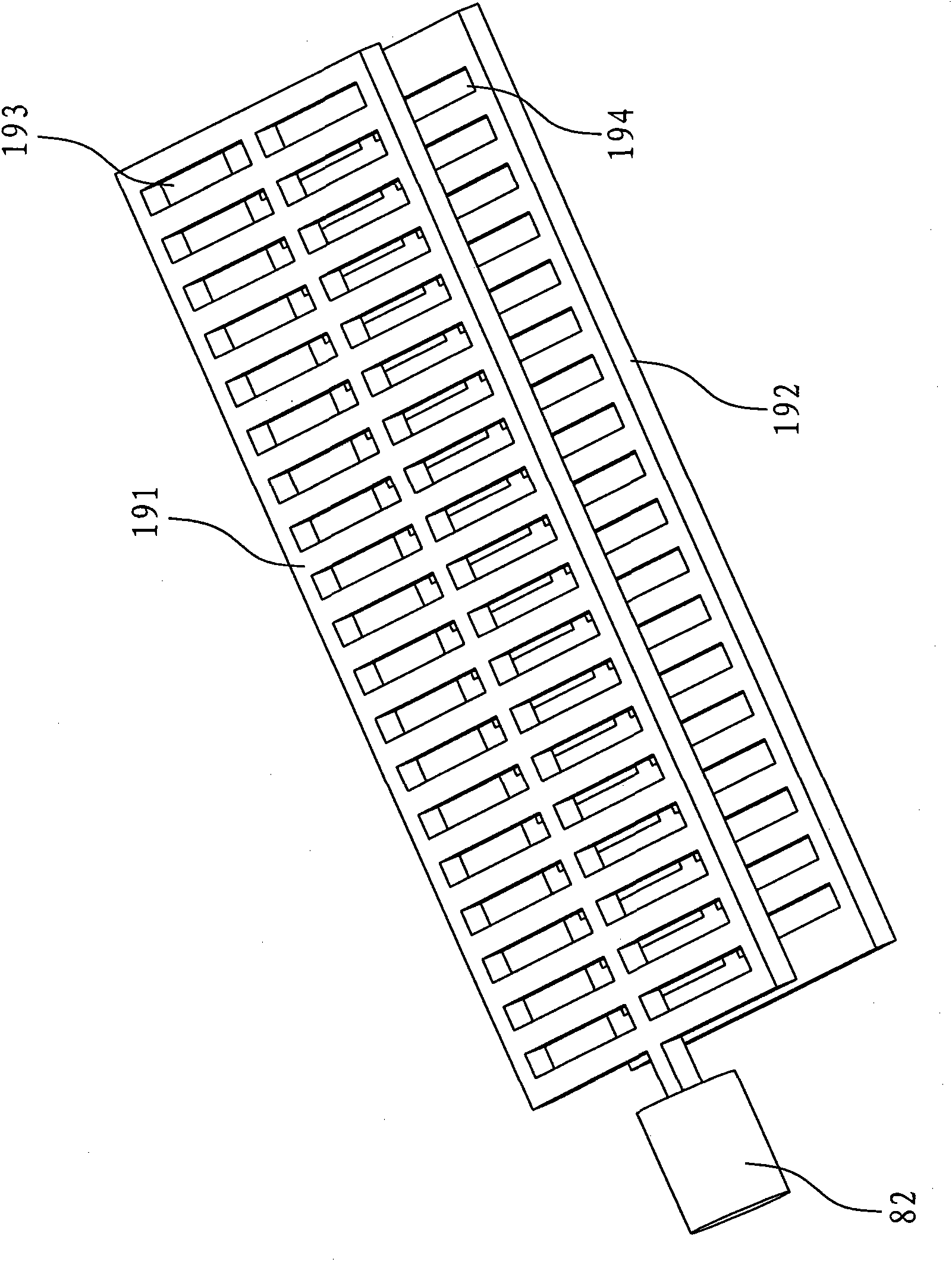

[0032] figure 1 As shown, the biomass gasification equipment mainly includes a gasifier 1 , a clean room, a liquid separation tank 5 and a gas storage tank 6 . The gasifier 1 mainly includes a hopper 11, a pressing bin 12 with a pressing mechanism, a combustion chamber 13, and a carbon outlet 14. The hopper 1 is arranged above the pressing bin 12, and a combustion chamber 13 is arranged below the pressing bin 12. The combustion chamber The bottom of 13 is provided with a fire grate 19 and an air outlet pipe 16, a temperature sensor 18 is provided on the side wall of the combustion chamber 13 at the top of the fire grate 19, an air outlet pipe 16 is arranged on the side wall of the combustion chamber 13 below the fire grate 19, and the lower part of the air outlet pipe 16 is connected The gas outlet 161 below the combustion chamber 13 is provided with a carbon outlet 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com