Abrasive belt automatic feeding mechanism

An automatic feeding and abrasive belt technology, applied in abrasive belt grinders, grinding drives, grinding machine parts, etc., can solve the problems of difficult operation, large waste, unstable feed rate, etc. The effect of stable quantity, reasonable structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

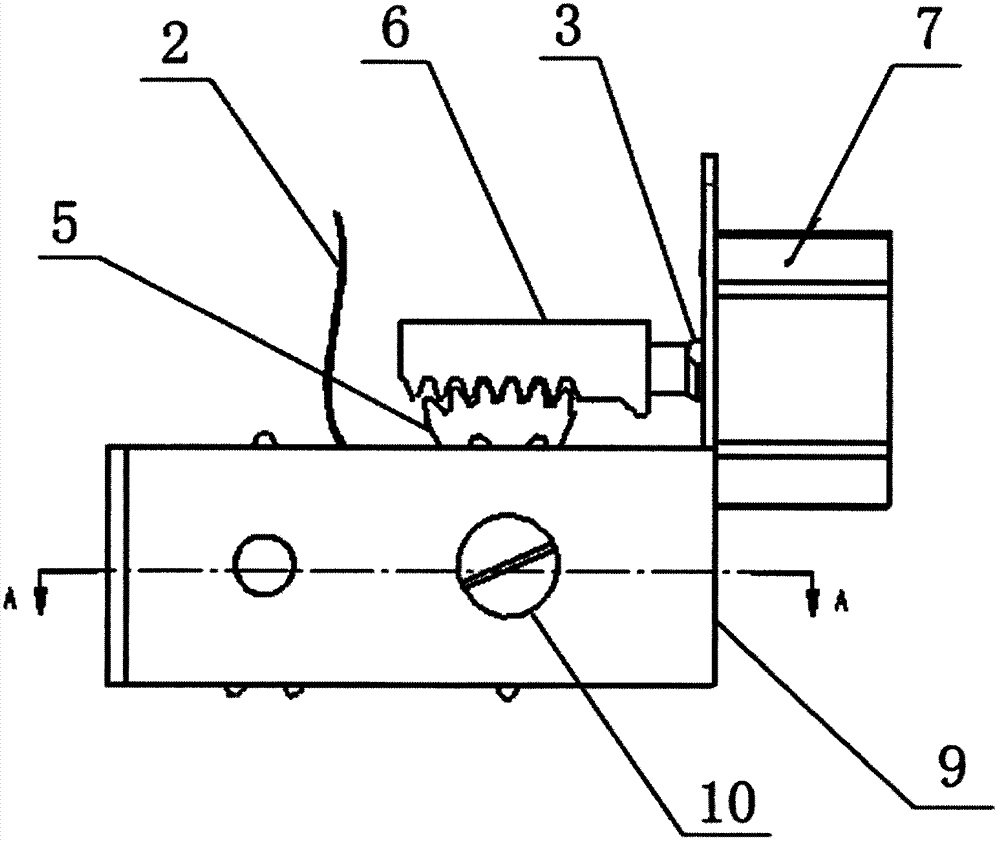

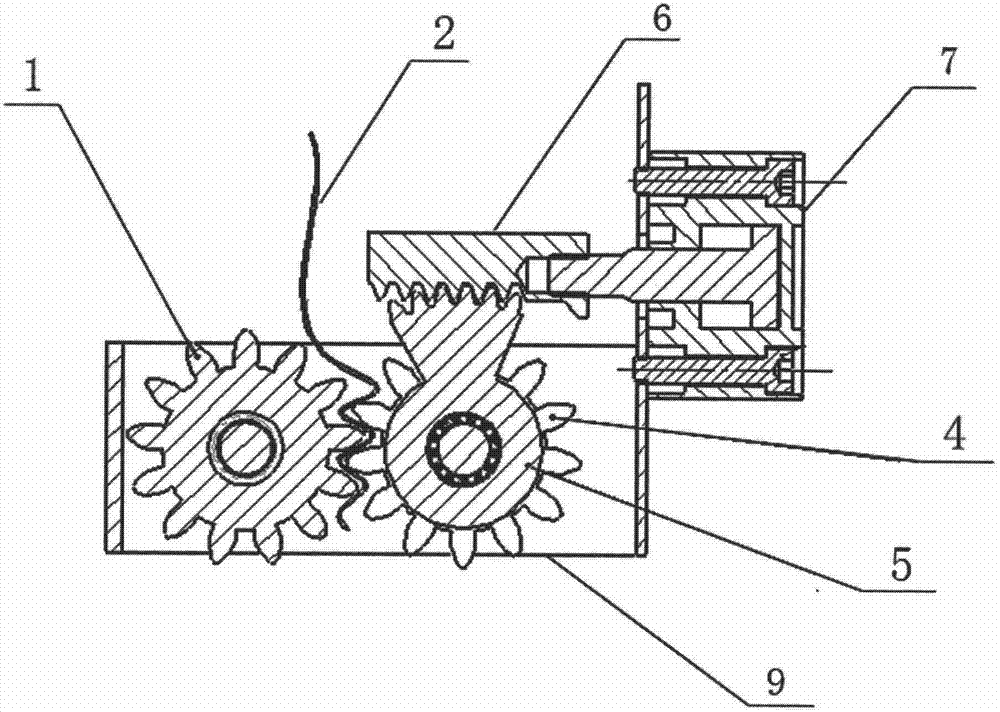

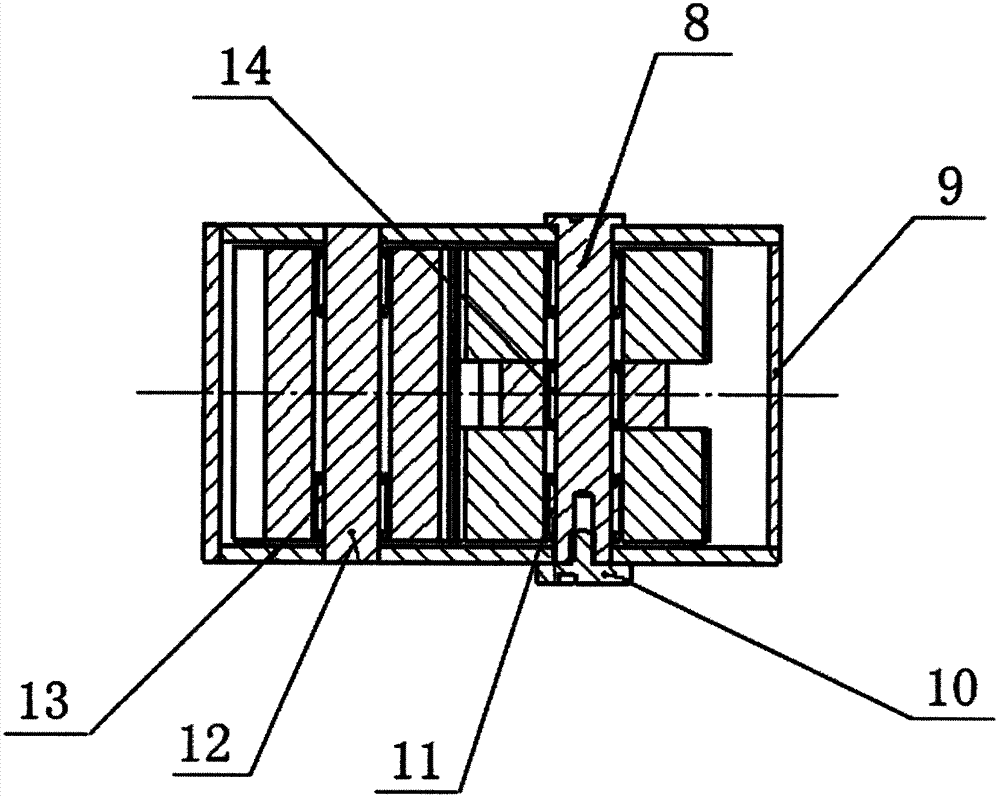

[0017] Such as Figure 1~3 Shown, a kind of abrasive belt automatic feeding mechanism comprises feeding cylinder 7, feeding rack 6, tape cassette 9, and long gear 1, two short gears 4, feed Sector gear 5, fixed shaft 12 and feed shaft 8, fixed shaft 12 passes through the long gear 1 that one-way needle roller bearing II13 is installed at both ends and is fixed on the tape cassette 9 front ends, and feed shaft 8 passes through the single The short gear 4 of the needle roller bearing I11, the feed sector gear 5 with the one-way needle roller bearing III14 and another short gear 4 with the one-way needle roller bearing I11 installed are installed in the middle part of the tape cassette 9, two The short gear 4 meshes with the long gear 1 at the same time, and the two ends of the feed shaft 8 are installed in the symmetrical mounting holes on both sides of the tape cassette 9; the feed cylinder 7 is fixed on the outside of the rear end of the tape cassette 9, and the feed gear The...

Embodiment 2

[0021] Such as Figure 1~3 Shown, a kind of abrasive belt automatic feeding mechanism comprises feeding cylinder 7, feeding rack 6, tape cassette 9, and long gear 1, two short gears 4, feed Sector gear 5, fixed shaft 12 and feed shaft 8, fixed shaft 12 passes through the long gear 1 that one-way needle roller bearing II13 is installed at both ends and is fixed on the tape cassette 9 front ends, and feed shaft 8 passes through the single The short gear 4 of the needle roller bearing I11, the feed sector gear 5 with the one-way needle roller bearing III14 and another short gear 4 with the one-way needle roller bearing I11 installed are installed in the middle part of the tape cassette 9, two The short gear 4 meshes with the long gear 1 at the same time, and the two ends of the feed shaft 8 are installed in the symmetrical mounting holes on both sides of the tape cassette 9; the feed cylinder 7 is fixed on the outside of the rear end of the tape cassette 9, and the feed gear The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com