Full-automatic nonmetal laser machining equipment

A laser processing and non-metal technology, applied in metal processing equipment, laser welding equipment, welding equipment, etc., can solve difficult processing and other problems, and achieve the effect of high automation, wide compatibility, stable and reliable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

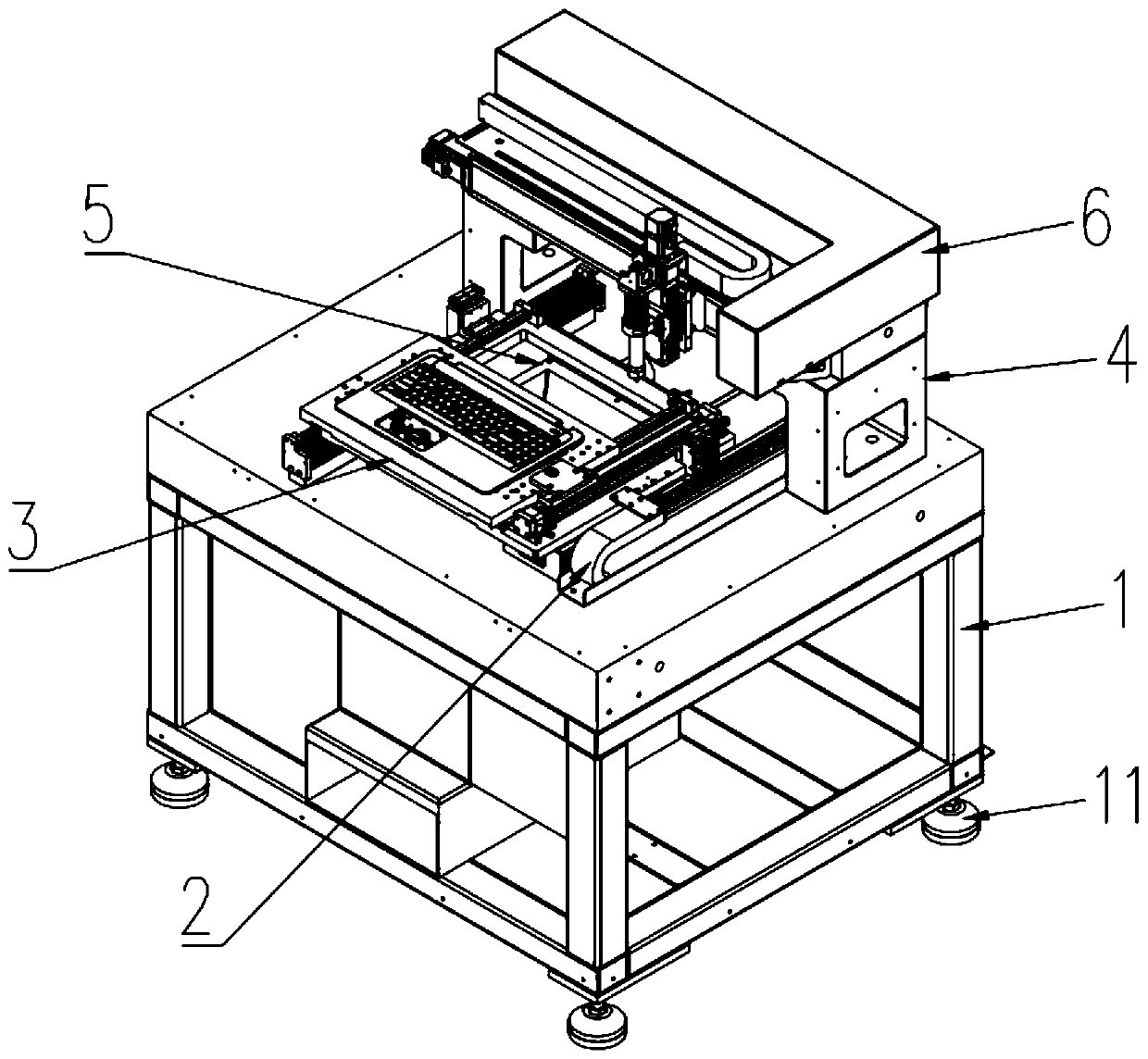

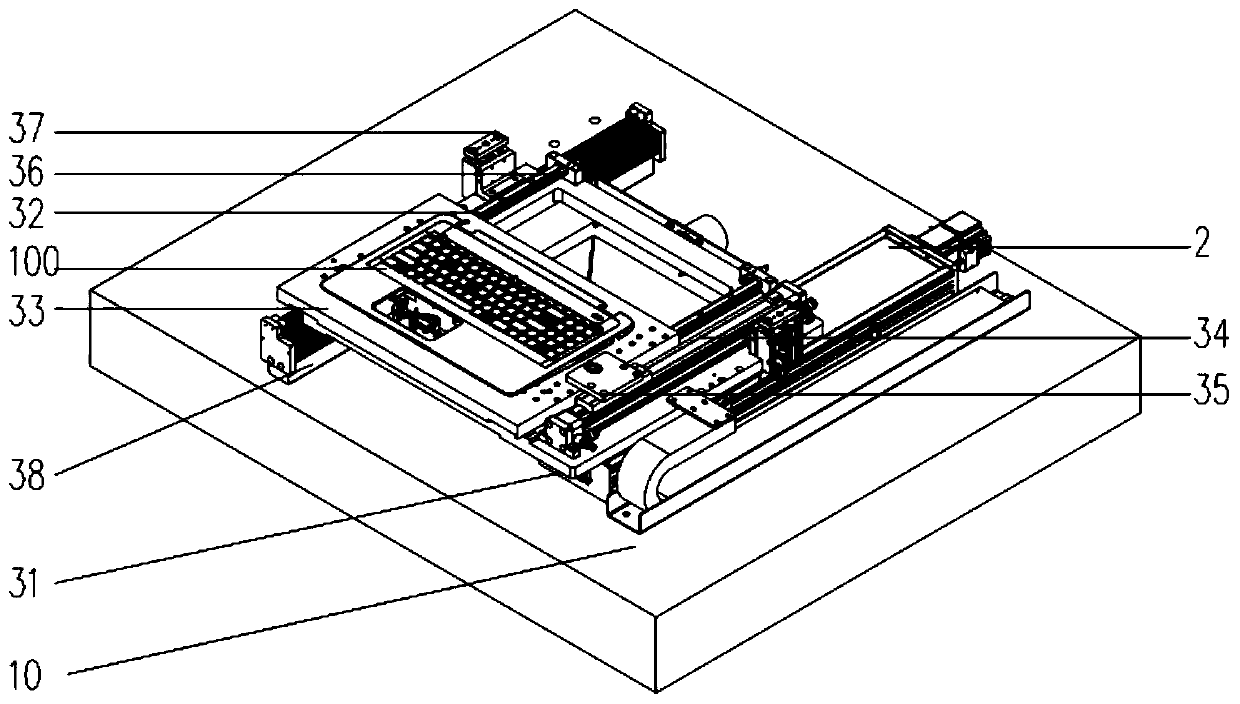

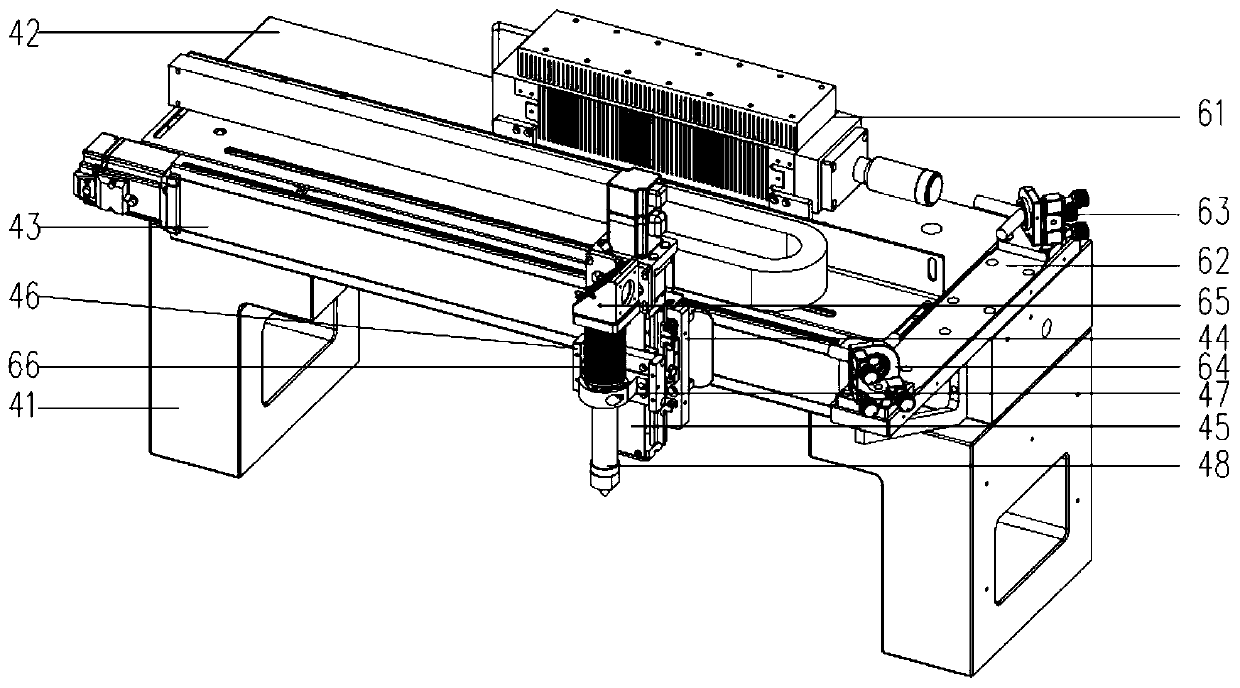

[0043] refer to figure 1 , is a kind of full-automatic non-metallic laser processing equipment described in the present invention, comprises equipment support 1, and the upper side of this equipment support forms work table top 10, is respectively defined as X with two mutually perpendicular side directions of this work table top In the Y direction and the Y direction, the Y-axis module 2, the Y-direction jig movement module 3, the laser processing module 4, the material receiving box 5 and the laser module 6 are arranged on the working table. In this embodiment, the equipment support 1 is a square steel frame, and the four-corner bottom plates of the square steel frame are respectively provided with installation feet 11, and the working table 10 is a granite platform. Each module will be described in detail later in conjunction with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com