Process for preparing 1, 1, 1-trifluoroethane and 1, 1, 1-difluorochloroethane

A technology of difluorochloroethane and trifluoroethane, which is applied in the field of preparation of halogenated hydrocarbons, can solve the problems of rising production cost, large equipment investment, complicated recovery process, etc. concise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

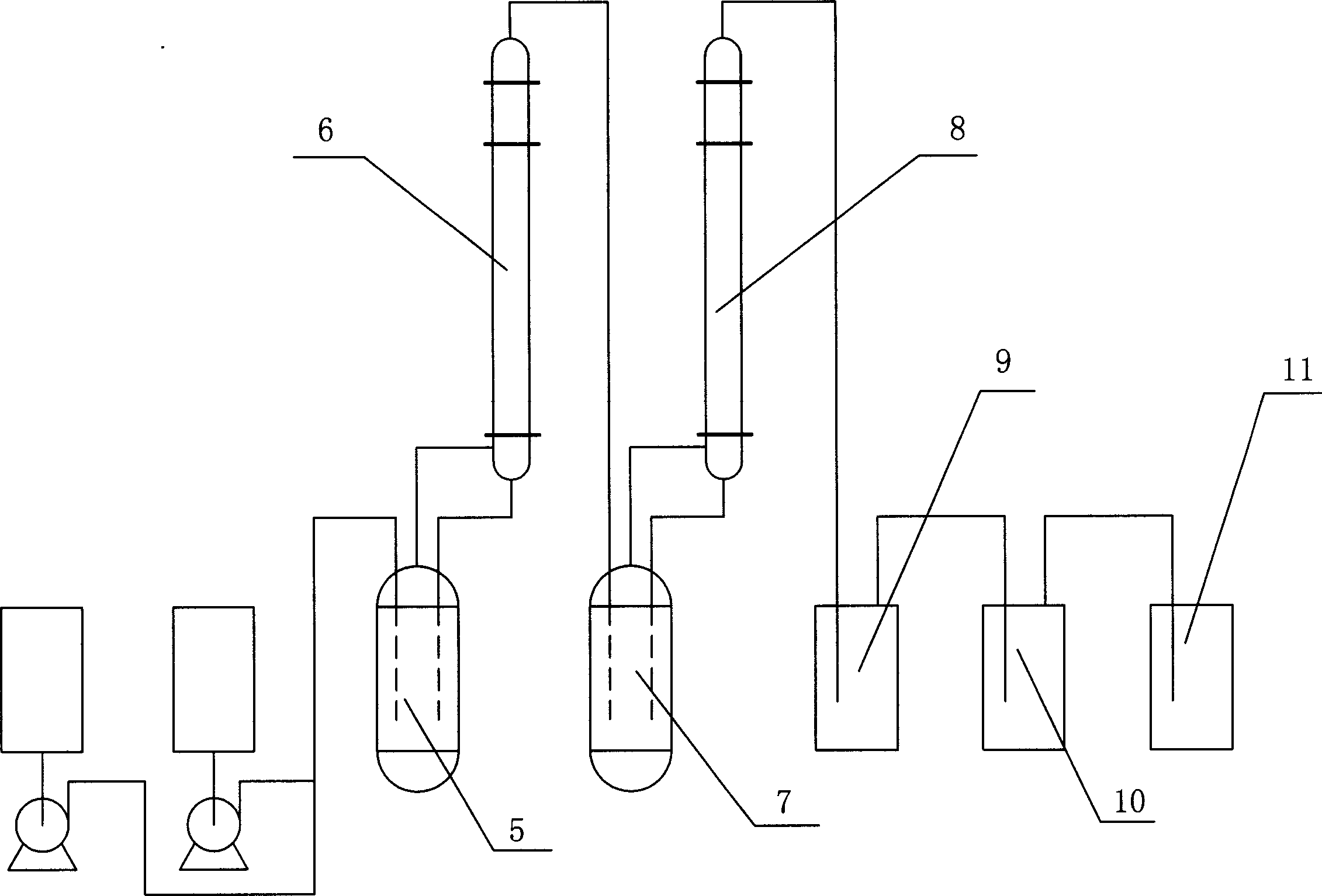

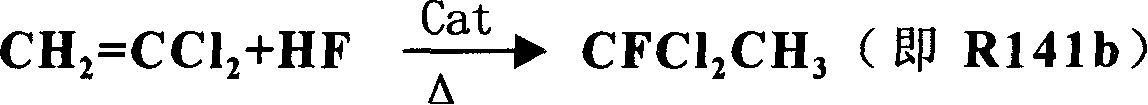

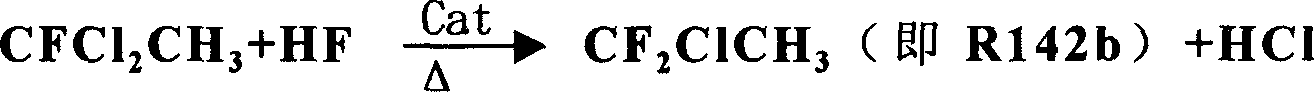

[0024] Example 1: see attached figure 1 shown, first put 200g SnCl 4 The catalyst and 300g of anhydrous HF were pressed into the 1000ml steel first reactor 5 with a reflux tower 6, and the temperature was raised to 55°C; 20g of SbCl 5 The catalyst and 400 g of R142b primer were pressed into a 1000 ml steel second reaction kettle 7 with a reflux tower 8, and the temperature was raised to 50°C. Then, start to pump anhydrous hydrogen fluoride at a speed of 56g / h and vinylidene chloride at a speed of 97g / h to react in the first reactor 5, when the pressure in the first reactor 5 reaches 1.2Mpa, from The reflux tower top of the first reactor 5 introduces the reaction material into the second reactor 7 for further reaction. When the pressure of the second reaction kettle 7 reaches 1.0Mpa, the reaction product starts to be drawn from the reflux tower top of the second reaction kettle 7, and the reaction product is collected in the gas cabinet 11 after the water washing tower 9 and ...

Embodiment 2-4

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com