A kind of anti-atomic oxygen polyimide composite film and preparation method thereof

An oxygen polyimide, polyamic acid gel film technology, applied in the coating and other directions, can solve the problems of sharp physical or chemical interaction at the interface, cracking or peeling of the protective layer, low adhesion of the protective layer, etc. The effect of simple chemical forming process, maintaining mechanical properties, and controllable film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

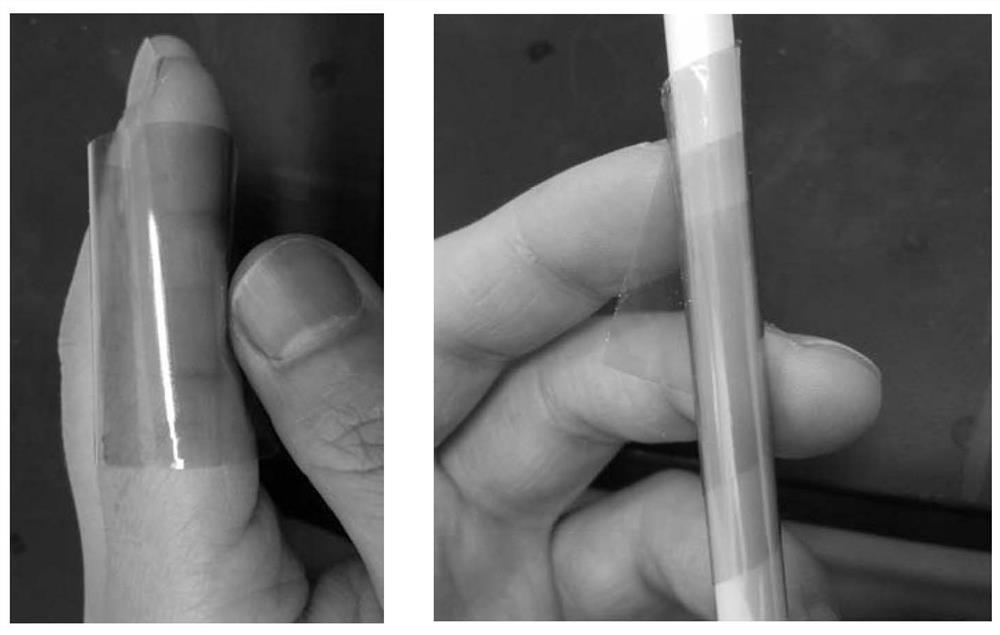

Method used

Image

Examples

preparation example Construction

[0044]Preparation of polyamic acid resin solution. Under stirring conditions, dissolve the diamine in the organic solvent, add the dianhydride monomer in batches (at least twice), and continue stirring at room temperature (15-30°C) for 3-12 hours to obtain a polyamic acid resin solution . The solid content of the obtained polyamic acid resin solution may be 10-25 wt%. Among them, the diamine can be 4,4'-diaminodiphenyl ether (4,4'-ODA), p-phenylenediamine (p-PDA), m-phenylenediamine (m-PDA), 2,2-bis [4-(4-aminophenoxy)phenyl]propane (BAPP), 3,3'-diaminodiphenyl ether (3,3'-ODA) or 1,3-bis(4-aminophenoxy ) At least one of benzene (TPER). The dianhydride can be pyromellitic dianhydride (PMDA), 2,3',3,4'-biphenyltetracarboxylic dianhydride (a-BPDA), 3,3',4,4'-biphenyltetracarboxylic acid Dianhydride (s-BPDA), 4,4'-oxydiphthalic anhydride (ODPA), 4,4'-(hexafluoroisopropylene) diphthalic anhydride (6FDA), 4,4'-(4, At least one of 4'isopropyldiphenoxy)bis(phthalic anhydride) (B...

Embodiment 1

[0062] 1) Put 80kg of dimethylacetamide solvent (DMAC) and 9.57kg of 4,4'-diaminodiphenyl ether (ODA) into the dry reaction kettle, stir until ODA is completely dissolved, then slowly add pyromellitic acid in turn Dianhydride (PMDA) 5kg, 3kg, 2kg and 0.43kg, feed intake interval 1 hour each time, continue to stir at room temperature for 8 hours, obtain the polyamic acid resin (substrate solution) that solid content is 20%;

[0063] 2) Weigh 518 grams of 4,4'-diaminodiphenyl ether (ODA) and dissolve it in a mixed solvent consisting of 2.63 kg of dioxane and 3.95 kg of dimethylacetamide solvent (DMAC), and weigh 367 grams of Pyrellitic dianhydride (PMDA) was added into the above solution twice, and stirred at room temperature for 2 hours; continue to add 500 grams of aminobis-blocked polysiloxane (wherein, R is vinyl, T is methyl, a=10.3, b=3.2), after stirring for 1 hour, slowly add 295.4 grams of PMDA, and stir overnight at room temperature to obtain a polyamic acid / polysiloxa...

Embodiment 2

[0070] The preparation process of the preparation method of the anti-atomic oxygen polyimide film in this embodiment 2 refers to implementation 1, the difference is only: the wet coating amount of the transition layer in step 5) is about 50g / m 2 , step 6) in the coating amount of atomic oxygen protection layer is about 20g / m 2 . In the obtained anti-atomic oxygen polyimide film, the thickness of the substrate is about 30 μm, the thickness of the transition layer is about 7.5 μm, and the thickness of the anti-atomic oxygen layer is about 9 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com