Cold-rolled non-oriented silicon steel with high magnetic induction and low iron loss for high-efficiency motor and manufacture method thereof

A technology of oriented silicon steel and manufacturing method, which is applied in the field of iron and steel metallurgy and processing, can solve problems such as unclear reasons, and achieve the effects of low equipment requirements, strong process versatility, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

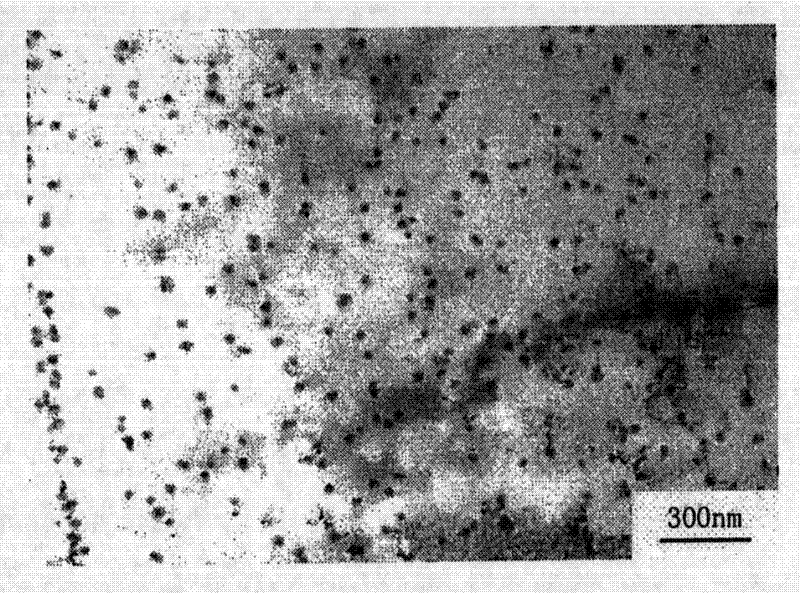

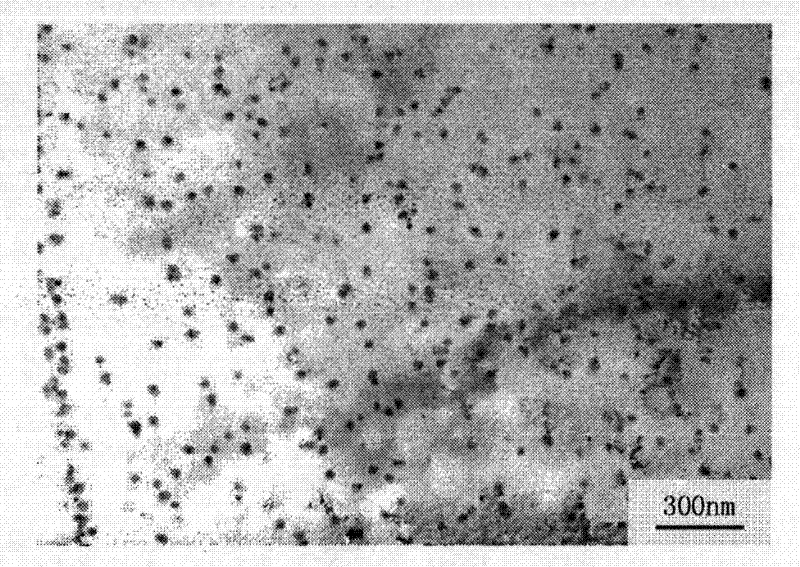

Image

Examples

Embodiment 1

[0020] The chemical composition (by weight percentage) is: C: 0.0046, Si+Al=1.09+0.05, Mn: 0.59, P: 0.0045%, S: 0.0014%, N: 0.0045%, Cu: 0.38, the rest is iron and For the forged billet that avoids impurities, after soaking at 1100°C, it is hot-rolled 5 times, the total reduction rate is 90%, and the reduction rate per pass is 25-40%, that is, from 20mm→12mm→7.2mm→4.4 mm→2.7mm→2.0mm. The finish rolling temperature is 910°C, and the coiling temperature is 540°C. After the hot-rolled sheet is pickled and descaled, it is cold-rolled to a finished product thickness of 0.5mm by a cold-rolling method, and then dried in 25% H 2 +75%N 2 (dew point below 0°C) Finish annealing in a protective atmosphere. The magnetic properties of the resulting finished product are: B 50 =1.72T, iron loss P 1.5 = 3.98W / kg.

Embodiment 2

[0022] The chemical composition (by weight percentage) is: C: 0.0041, Si+Al=1.12+0.14, Mn: 0.56, P: 0.0048%, S: 0.0016%, N: 0.0044%, Cu: 0.17, the rest is iron and For the forged billet that avoids impurities, after soaking at 1150°C, it is hot-rolled for 5 passes, the total reduction rate is 90%, and the reduction rate for each pass is 25-40%, that is, from 21mm→12.6mm→7.6mm→ 4.6mm→2.8mm→2.0mm. The finish rolling temperature is 950°C, and the coiling temperature is 560°C. After the hot-rolled sheet is pickled and descaled, it is cold-rolled to a finished product thickness of 0.5mm by a cold-rolling method, and then dried in 25% H 2 +75%N 2 (dew point below 0°C) Finish annealing in a protective atmosphere. The magnetic properties of the resulting finished product are: B 50 =1.71T, iron loss P 1.5 = 3.94W / kg.

Embodiment 3

[0024] The chemical composition (by weight percentage) is: C: 0.0045, Si+Al=1.10+0.11, Mn: 0.58, P: 0.0046%, S: 0.0013%, N: 0.0023%, Cu: 0.30, the rest is iron and For the forged billet that avoids impurities, after soaking at 1150°C, it is hot-rolled for 5 passes, the total reduction rate is 91%, and the reduction rate for each pass is 30-40%, that is, from 23mm→13.8mm→8.3mm→ 5.1mm→3.2mm→2.1mm. The finish rolling temperature is 940°C, and the coiling temperature is 550°C. After the hot-rolled sheet is pickled and descaled, it is cold-rolled to a finished product thickness of 0.5mm by a cold-rolling method, and then dried in 25% H 2 +75%N 2 (dew point below 0°C) Finish annealing in a protective atmosphere. The magnetic properties of the resulting finished product are: B 50 =1.72T, iron loss P 1.5 = 3.95W / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com