Zero emission treatment method of completely turning chromium-containing waste liquor into useable resources.

A treatment method and recycling technology, which is applied in the field of zero-discharge treatment of all chromium-containing waste liquids, can solve the problems of groundwater and surface water pollution, and achieve the effects of reducing treatment costs, easy control of process conditions, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

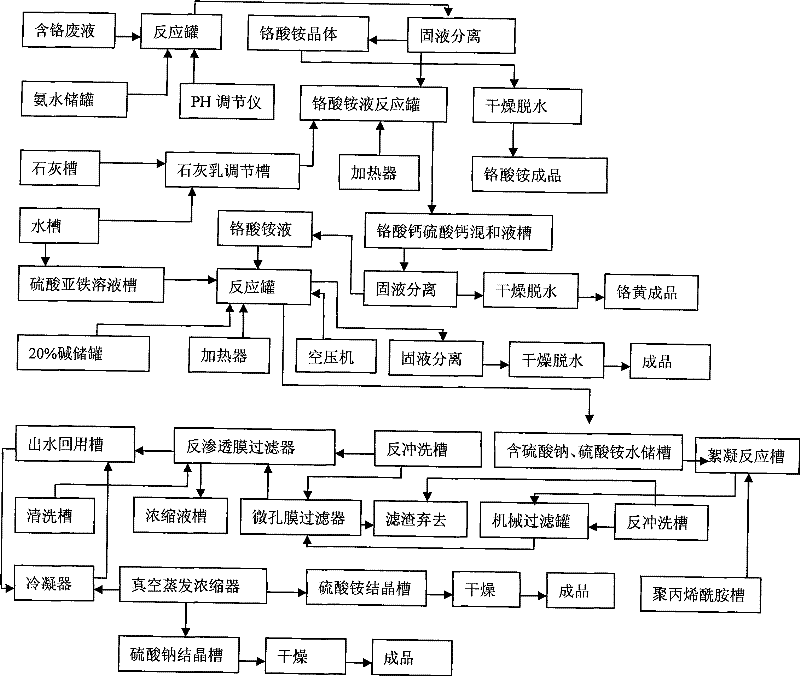

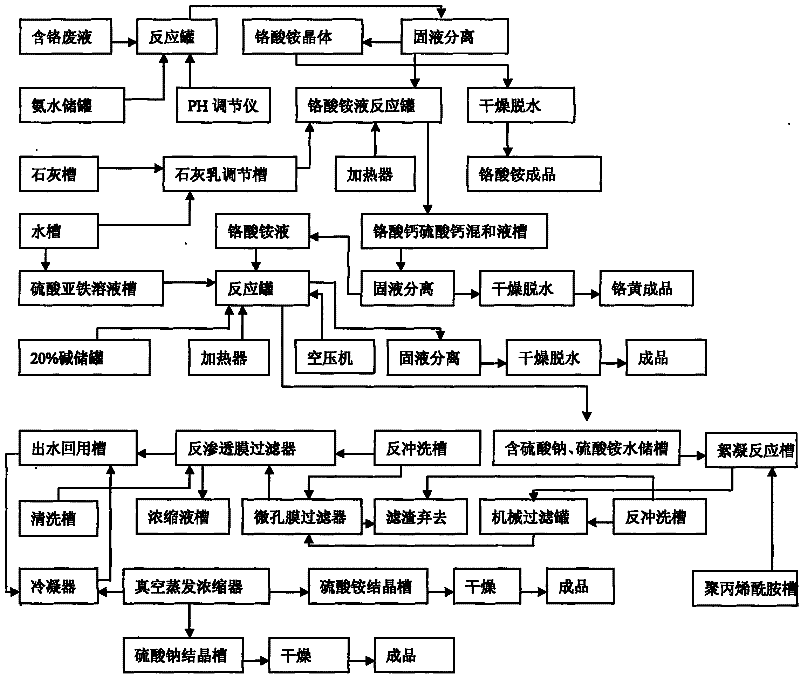

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. The experimental methods without specific conditions indicated in the following examples are usually in accordance with conventional conditions, or in accordance with the conditions suggested by the manufacturer, unless otherwise specified.

[0020] The embodiment is described in conjunction with the process flow of the accompanying drawings.

[0021] The chromium-containing waste liquid is pumped from the storage tank to the reaction tank, and at the same time, the ammonia water with a concentration of 15% by weight is pumped from the ammonia water storage tank to the reaction tank, and the pH is adjusted to 7 with an automatic pH value controller to control the amount of ammonia water added. After reacting at room temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com