A kind of high-strength copper-containing cold-rolled non-oriented silicon steel and manufacturing method

A technology of oriented silicon steel and a manufacturing method, applied in the field of steel processing, can solve the problems of high frequency iron loss, difficult realization of thin plate casting and rolling technology, etc., and achieve the effect of simple production process and strong process versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

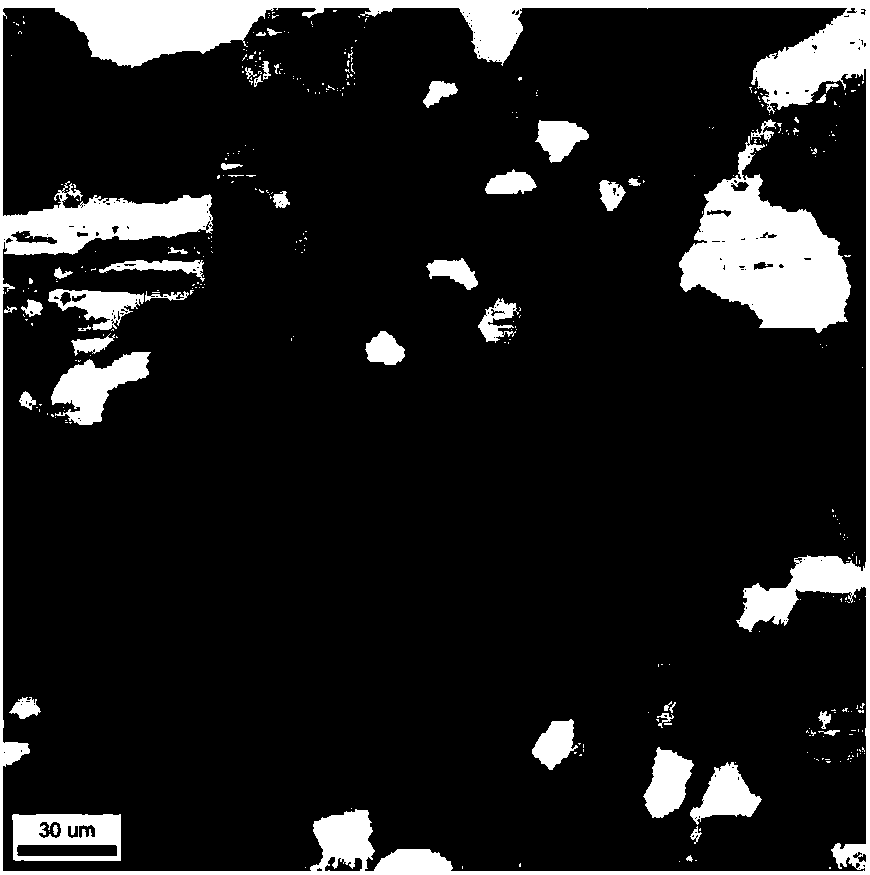

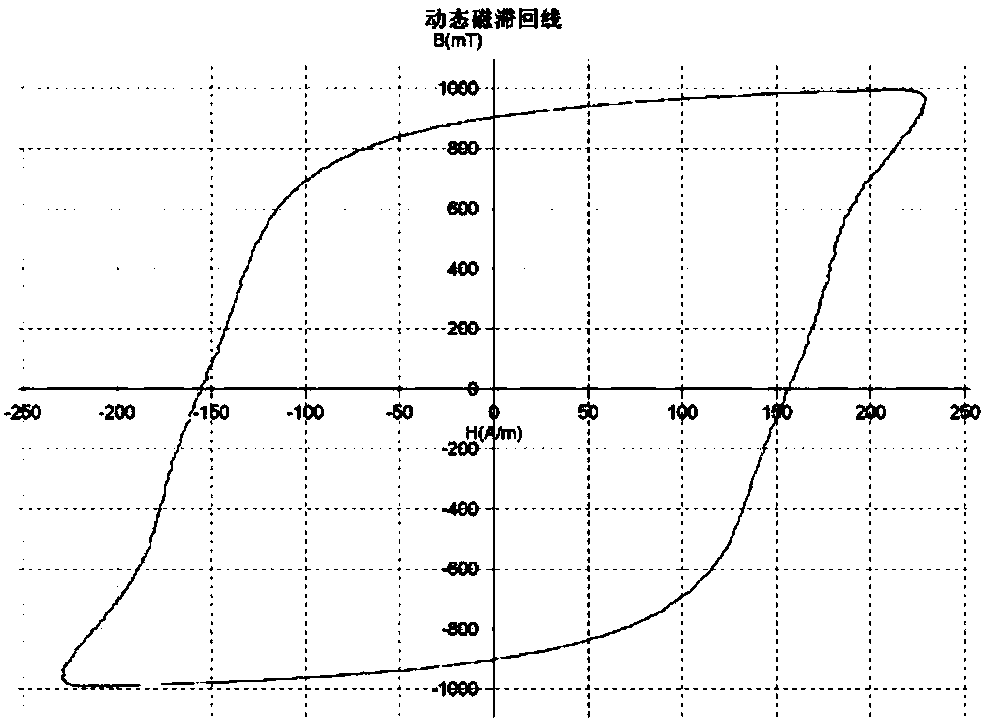

Image

Examples

Embodiment 1

[0027] The chemical composition (by mass percentage) is: 0.0013% C, 0.53% Mn, 0.80% Al, 2.84% Si, 0.0030% N, 0.0027% Nb, 0.0018% S, 0.0045% P, 1.8% Cu, 1.2% Ni, The rest is iron and unavoidable impurities.

[0028] After being held at 1150°C for 1.5h, the forged billet was rolled for 7 passes through the rolling mill. The total reduction rate was 94%, the reduction rate for each pass was 31%, and the final rolling temperature was 870°C. Keep the temperature at 650°C for 1 hour and then cool with the furnace. Then the hot-rolled sheet was dried at 980°C and 100% N 2 Incubate for 5 min under a protective atmosphere and take it out to cool to room temperature. After the normalized sheet is pickled to remove the scale, it is cold-rolled to 0.5mm, and then the cold-rolled sheet is dried at 850°C and 25%H 2 +75%N 2 Insulate for 3 min under a protective atmosphere, then remove and air cool to room temperature. The annealed sheet is subjected to a second cold rolling to 0.35mm, a...

Embodiment 2

[0031] The chemical composition (by mass percentage) is: 0.0015% C, 0.62% Mn, 0.91% Al, 2.92% Si, 0.0030% N, 0.0025% Nb, 0.0018% S, 0.0045% P, 1.5% Cu, 0.8% Ni, The rest is iron and unavoidable impurities.

[0032] After the forged billet is heated at 1150°C, it is rolled through the rolling mill for 7 passes, the total reduction rate is 94%, the reduction rate of each pass is 31%, the final rolling temperature is 870°C, and then the hot-rolled sheet is rolled at 600°C Under the condition of heat preservation for 1h, it was cooled with the furnace. Then the hot-rolled sheet was dried at 1030°C and 100% N 2 Insulate for 3 minutes under a protective atmosphere and then take it out to air-cool. After the normalized sheet is pickled to remove the scale, it is cold-rolled to 0.5mm, and then the cold-rolled sheet is dried at 800 ° C and 25% H 2 +75%N 2 Insulate for 5 minutes under a protective atmosphere, then take it out and cool it to room temperature. Then the annealed plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com