A short-process preparation method of tc4 titanium alloy fine equiaxed structure and large-scale rods

An equiaxed structure and titanium alloy technology, which is applied in the field of short-process preparation of large-sized bars with shaft structure, can solve the problems of low yield, long production cycle and large grinding loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

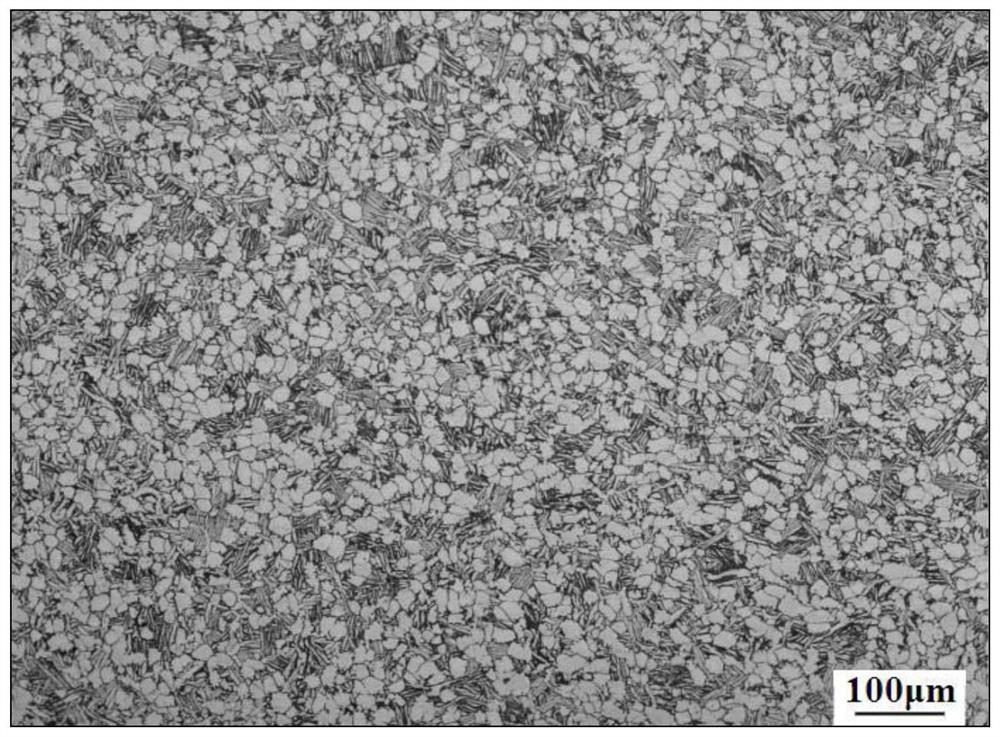

Embodiment 1

[0030] This embodiment includes the following steps:

[0031] Step 1. Peel the cylindrical 8TC4 titanium alloy ingot with a specification of Ф720mm×550mm (section diameter×length) to a specification of Ф690mm×550mm (section diameter×length), and then carry out 2 rounds of billet forging. Among them, the first The initial forging temperature of the first fire blank forging is 1150°C, the final forging temperature is 930°C, the total forging ratio is 8.4, air cooling after forging, the initial forging temperature of the second fire blank forging is 1070°C, and the final forging temperature is 930 ℃, the total forging ratio is 10.8, air-cooled after forging, and the surface of the TC4 titanium alloy ingot is subjected to surface grinding treatment after each fire forging, and the primary forging billet is obtained;

[0032] Step 2, the primary forging billet that obtains in step 1 is (T β Under the condition of -15℃), carry out 4 times of upsetting and drawing forging, wherein, ...

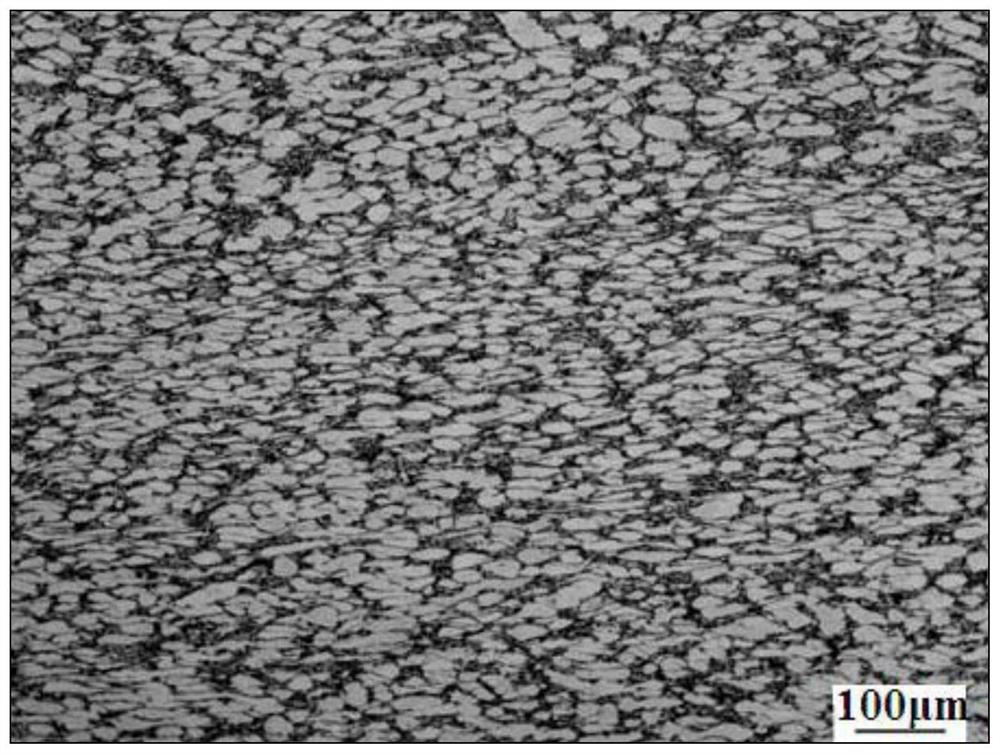

Embodiment 2

[0037] This embodiment includes the following steps:

[0038] Step 1. Peel the cylindrical TC4 titanium alloy ingot with a specification of Ф820mm×950mm (section diameter×length) to a specification of Ф790mm×550mm (section diameter×length), and then carry out 3 times of billet forging. Among them, the first The initial forging temperature of the first fire blank forging is 1150°C, the final forging temperature is 940°C, the total forging ratio is 6.0, air cooling after forging, the initial forging temperature of the second fire blank forging is 1100°C, and the final forging temperature is 920 ℃, the total forging ratio is 9.6, air cooling after forging, the initial forging temperature of the third fire forging is 1050°C, the final forging temperature is 920°C, the total forging ratio is 10.2, air cooling after forging, and the billet opening for each fire After forging, the surface of the TC4 titanium alloy ingot is subjected to surface grinding treatment to obtain the primary...

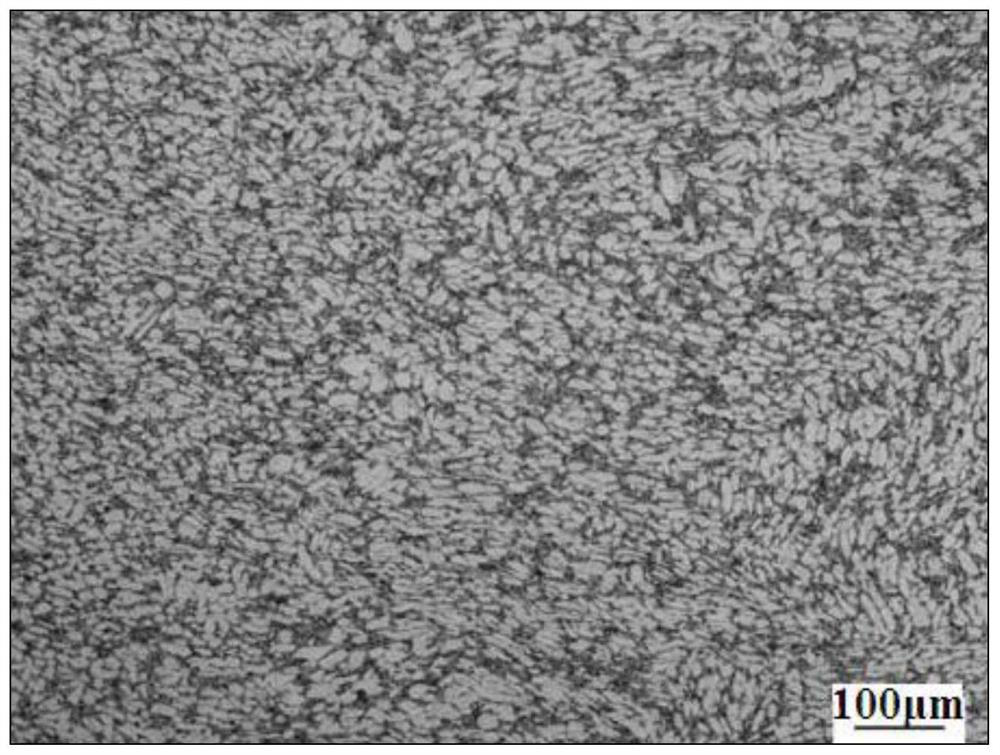

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] Step 1. Peel the cylindrical TC4 titanium alloy ingot with a specification of Ф640mm×550mm (section diameter×length) to a specification of Ф609mm×550mm (section diameter×length), and then carry out 3 times of billet forging. Among them, the first The initial forging temperature of the first billet forging is 1150°C, the final forging temperature is 910°C, the total forging ratio is 8.4, air cooling after forging, the initial forging temperature of the second billet forging and the third billet forging are the same The final forging temperature is 1070°C, the final forging temperature is 920°C, the total forging ratio is 10.2, air-cooled after forging, and the surface of the TC4 titanium alloy ingot is ground after each firing forging to obtain the primary forging billet;

[0046] Step 2, the primary forging billet that obtains in step 1 is (T β Under the condition of -25℃), carry out 3 times of upsetting forging, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com