An Ultrasonic Roller Structure for Rebar Rolling

A technology of threaded steel and rolls, which is applied in the field of threaded steel rolls, can solve the problem that ultrasonic rolls are difficult to continuously form ultrasonic interference, and achieve the effect of reducing ultrasonic energy loss and improving grain refinement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

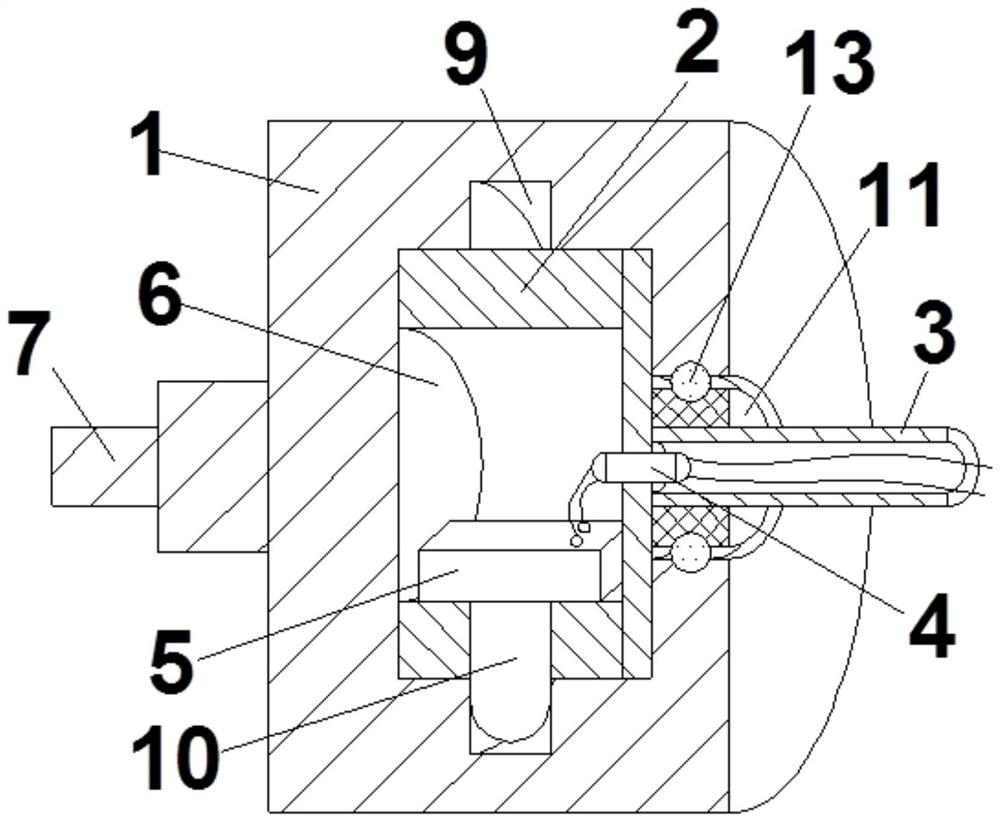

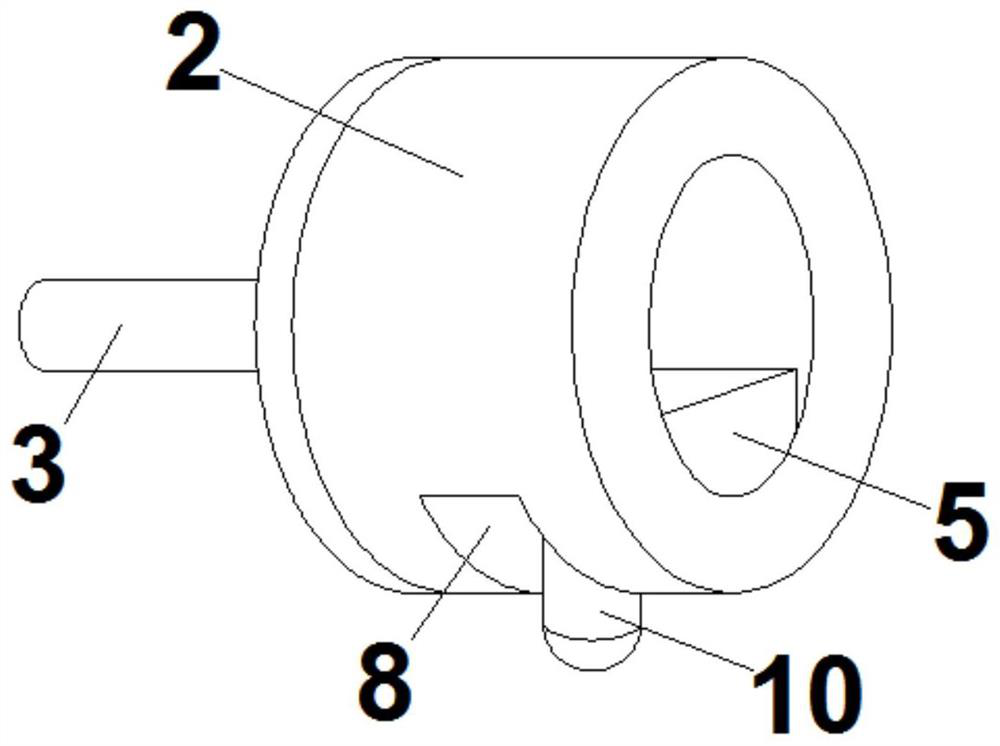

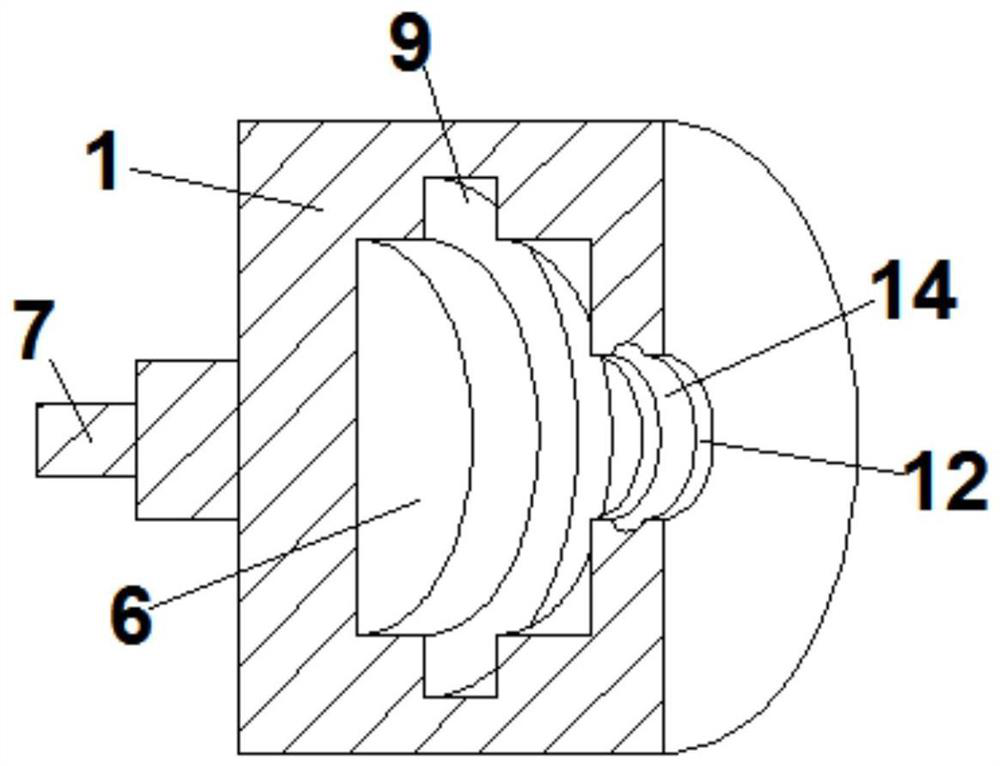

[0014] like Figure 1-Figure 3 As shown, an ultrasonic roll structure for threaded steel rolling includes a roll 1, a support wheel 2, the support wheel 2 is hollow inside, the support wheel 2 is closed at one axial end and is coaxially connected with a hollow support shaft 3, and the support wheel 2 A joint 4 is installed at the joint of the axial closed end corresponding to the support shaft 3. One end of the joint 4 extends into the support wheel 2, and the other end extends into the support shaft 3. An ultrasonic transmitter 5 is installed at the inner bottom of the support wheel 2. The ultrasonic transmitter The electrical connection end of 5 is connected to one end of the joint 4 through a wire, and the other end of the joint 4 is connected to a wire drawn out along the inside of the support shaft 3; the inside of the roll 1 has a circular groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com