Solution automatic addition system

A technology of automatic addition and solution, applied in electrical components, printed circuit manufacturing, removal of conductive materials by chemical/electrolytic methods, etc. Concentration reduction and other problems, to achieve the effect of easy correction and maintenance, improve accuracy, and reduce waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

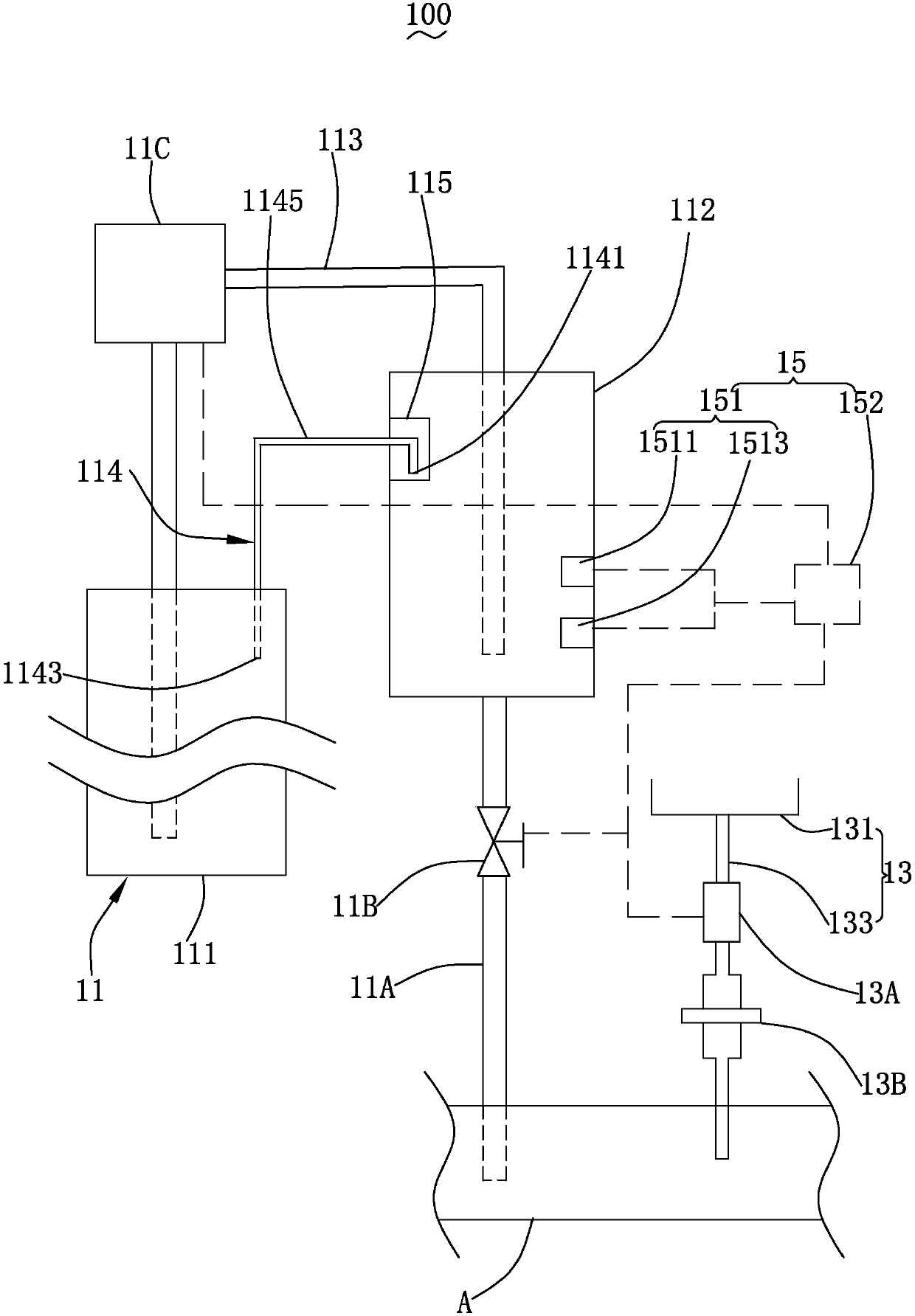

[0040] see figure 1 , is a structural schematic diagram of Embodiment 1 of the automatic solution adding system of the present invention. The automatic solution adding system 100 comprises a liquid medicine adding device 11, a defoamer adding device 13 and a control device 15, and the control device 15 is used to control the liquid medicine adding device 11 and the defoamer adding device 13 to Add chemical solution and defoamer to developing film removing cylinder A.

[0041] The liquid medicine adding device 11 includes a liquid medicine source 111 for providing the medicine liquid, a container 112 with a liquid outlet pipe 11A at the bottom, and a liquid medicine source 111 for transporting the liquid medicine in the liquid medicine source 111 to the container 112. The liquid inlet pipe 113 and the siphon pipe 114, the first control valve 11B is provided on the liquid outlet pipe 11A, the liquid pump 11C is provided on the liquid inlet pipe 113, and one end of the siphon pi...

Embodiment 2

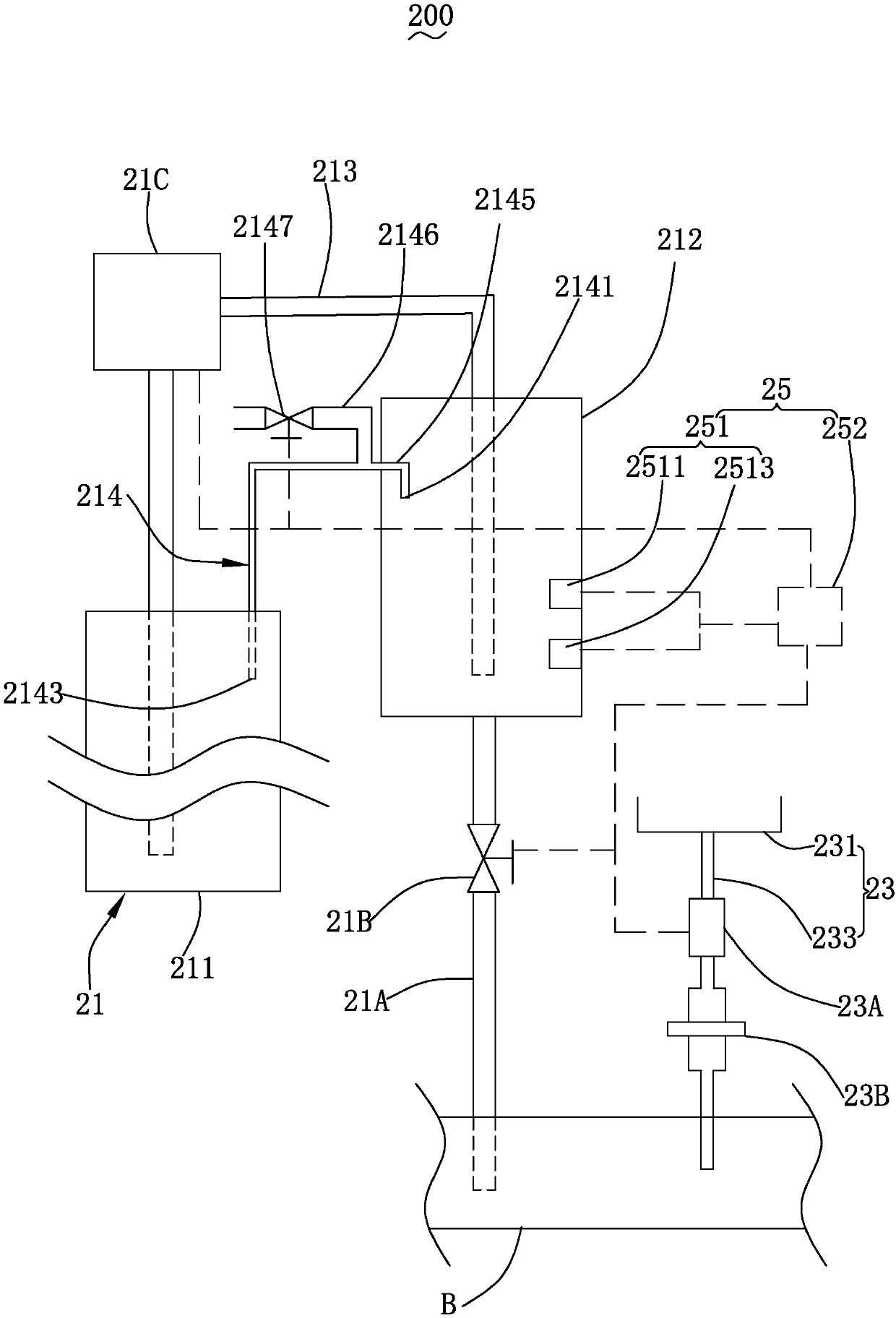

[0060] see figure 2 , is a structural schematic diagram of Embodiment 2 of the automatic solution adding system of the present invention. The automatic solution adding system 200 comprises a liquid medicine adding device 21, a defoamer adding device 23 and a control device 25, and the control device 25 is used to control the liquid medicine adding device 21 and the defoamer adding device 23 to Add chemical solution and defoamer to developing film removing cylinder B.

[0061] The liquid medicine adding device 21 includes a liquid medicine source 211 for providing liquid medicine, a container 212 with a liquid outlet pipe 21A at the bottom, and a liquid medicine source 211 for transporting the liquid medicine in the liquid medicine source 211 to the container 212. The liquid inlet pipeline 213 and the siphon pipeline 214, the first control valve 21B is arranged on the described liquid outlet pipeline 21A, the liquid pump 21C is arranged on the described liquid inlet pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com