Quantitative feeding device for casting spheroidal graphite cast iron

A feeding device and storage bin technology, applied in casting equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as waste products, synchronization, poor operation safety, unstable auxiliary material addition effect, etc., to ensure time , avoid instability and other interference factors, and increase the effect of operational stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

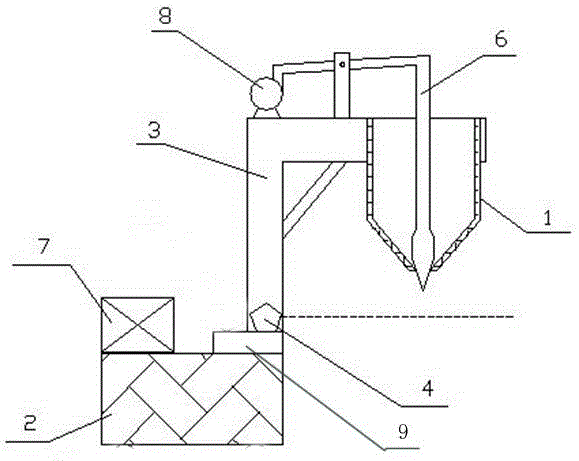

[0011] Below in conjunction with figure, the present invention will be further described:

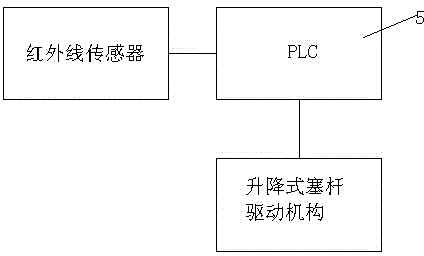

[0012] The quantitative feeding device for casting ductile iron includes a storage bin 1, the storage bin 1 is fixed on the cantilever 3, the cantilever 3 is arranged on the support frame 2 through the turntable 9, an infrared sensor 4 is arranged on the support frame 2, and the storage bin 1. The feeding direction is in the same plane as the detection direction of the infrared sensor 4. The storage bin 1 is provided with a lifting plug rod 6, and the PLC 5 is connected with the lifting plug rod driving mechanism 8. Infrared sensor 4 is connected with PLC5, and the described lifting type plug rod driving mechanism is connected with PLC5.

[0013] During the pouring operation, the molten iron is poured from the pouring ladle into the mold. The light emitted by the infrared sensor 4 is located on the channel path of the molten iron. After the metal blocks the light, the infrared sensor 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com