Beneficiation method for copper and lead zinc separation by adopting liquid sulfur dioxide

A liquid sulfur dioxide, sulfur dioxide technology, applied in the direction of solid separation, flotation, etc., can solve the problems of concentration effect of separation operation, unfavorable effective separation of copper and lead and zinc, etc., and achieve the effect of improving the concentration of pulp and improving the separation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

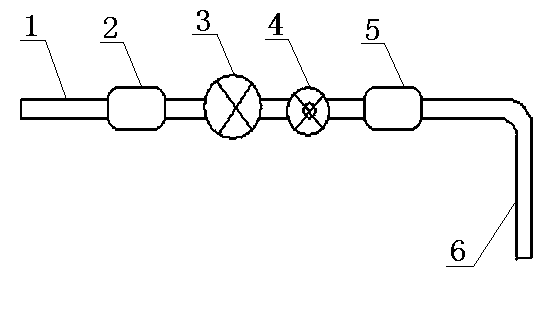

Image

Examples

Embodiment 1

[0022] The invention is used to carry out separation flotation of copper and lead-zinc on a certain copper-lead-zinc polymetallic sulfide ore. Add 200 g / ton of sodium sulfide and stir for 3 minutes under the condition of pulp concentration of 24%, then add sulfur dioxide 1000 g / ton and stir, the pulp concentration remains basically unchanged, and copper and lead-zinc are carried out under the condition of pulp pH value of 6.0. Sulfur separation and flotation to obtain coarse copper concentrate and lead-zinc mixed concentrate; the separation index is: separated feed copper grade 5.85%, lead grade 12.61%, zinc grade 23.32%; separated copper concentrate grade copper copper 19.46%, It contains 5.66% lead, 6.47% zinc, and a copper recovery rate of 80.59%; the lead-zinc mixed concentrate contains 1.50% copper; the lead recovery rate is 89.12%, and the zinc recovery rate is 93.27%.

Embodiment 2

[0028] The invention is used to carry out separation flotation of copper and lead-zinc on a certain copper-lead-zinc polymetallic sulfide ore. When the pulp concentration is 23.5%, add sodium sulfide 150 g / ton and stir for 3 minutes, then add sulfur dioxide 800 g / ton and stir. Copper rough concentrate and lead-zinc mixed concentrate were obtained by sulfur separation flotation; the separation indicators were: separated ore copper grade 3.37%, lead grade 12.10%, zinc grade 23.48%; separated copper concentrate grade copper copper 16.42%, containing Lead 4.58%, zinc 6.11%, copper recovery rate 79.63%; lead-zinc mixed concentrate contains copper 0.82%; lead recovery rate 93.82%, zinc recovery rate 95.75%.

Embodiment 3

[0034] The invention is used to carry out separation flotation of copper and lead-zinc on a certain copper-lead-zinc polymetallic sulfide ore. Add sodium sulfide 400 g / ton and stir for 4 minutes under the condition of pulp concentration of 26%, then add sulfur dioxide 1400 g / ton and stir, the pulp concentration is basically unchanged, and copper and lead-zinc are carried out under the condition of pulp pH value of 6.2. Sulfur separation and flotation to obtain coarse copper concentrate and lead-zinc mixed concentrate; the separation index is: the copper grade of the separated ore feed is 6.04%, the lead grade is 15.17%, and the zinc grade is 24.25%; the copper-copper grade of the separated copper concentrate is 20.37%, It contains 5.81% lead, 7.23% zinc, and a copper recovery rate of 88.25%; the lead-zinc mixed concentrate contains 0.96% copper; the lead recovery rate is 89.99%, and the zinc recovery rate is 92.20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com